Optical hole measuring device

An optical pick-up device and hole measuring technology, which is applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of large error and intensity, and no way to realize the operation, etc., and achieve the effect of easy handling, simple structure, and high optical density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0030] Hereinafter, embodiments of the present invention will be described based on the drawings.

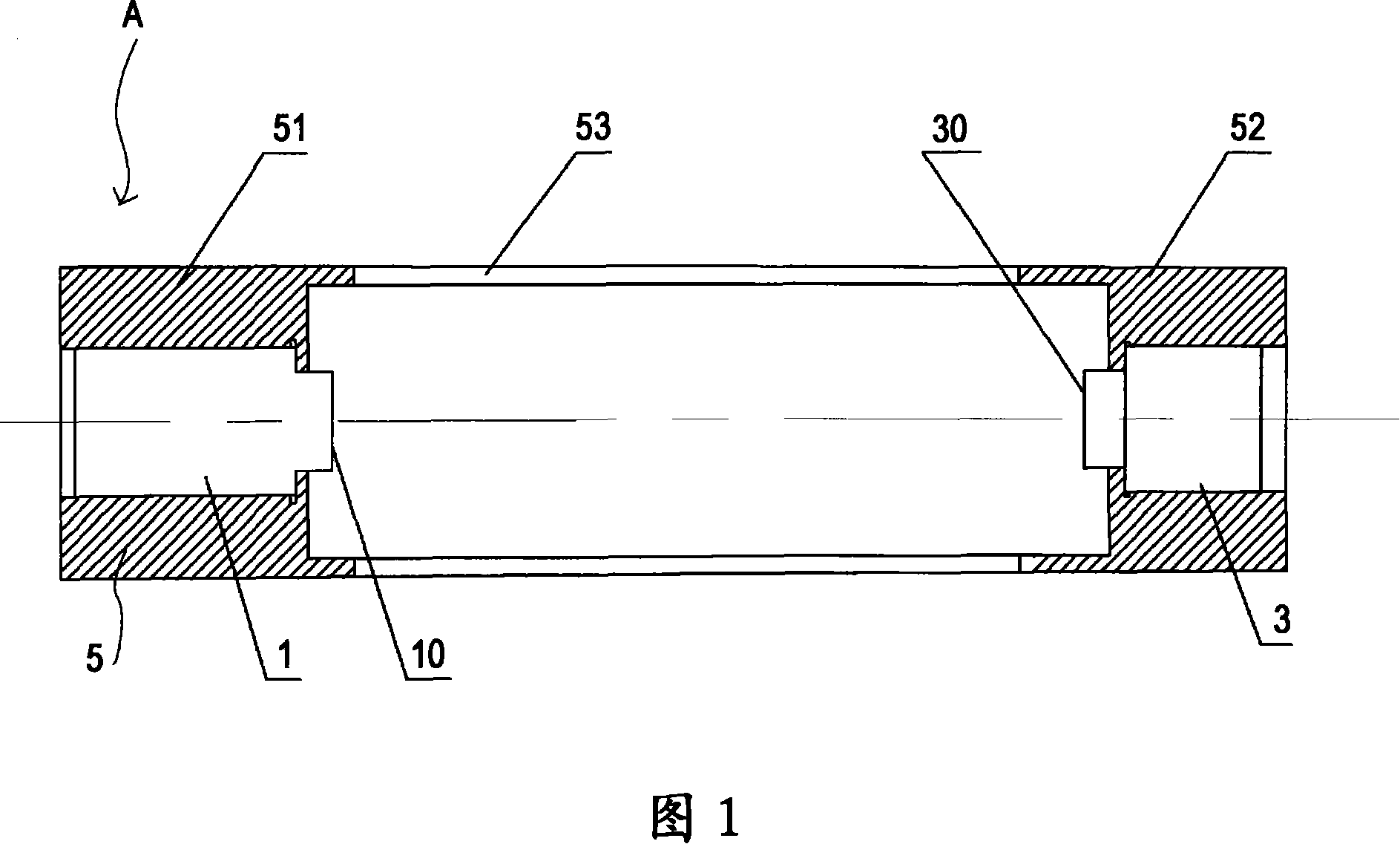

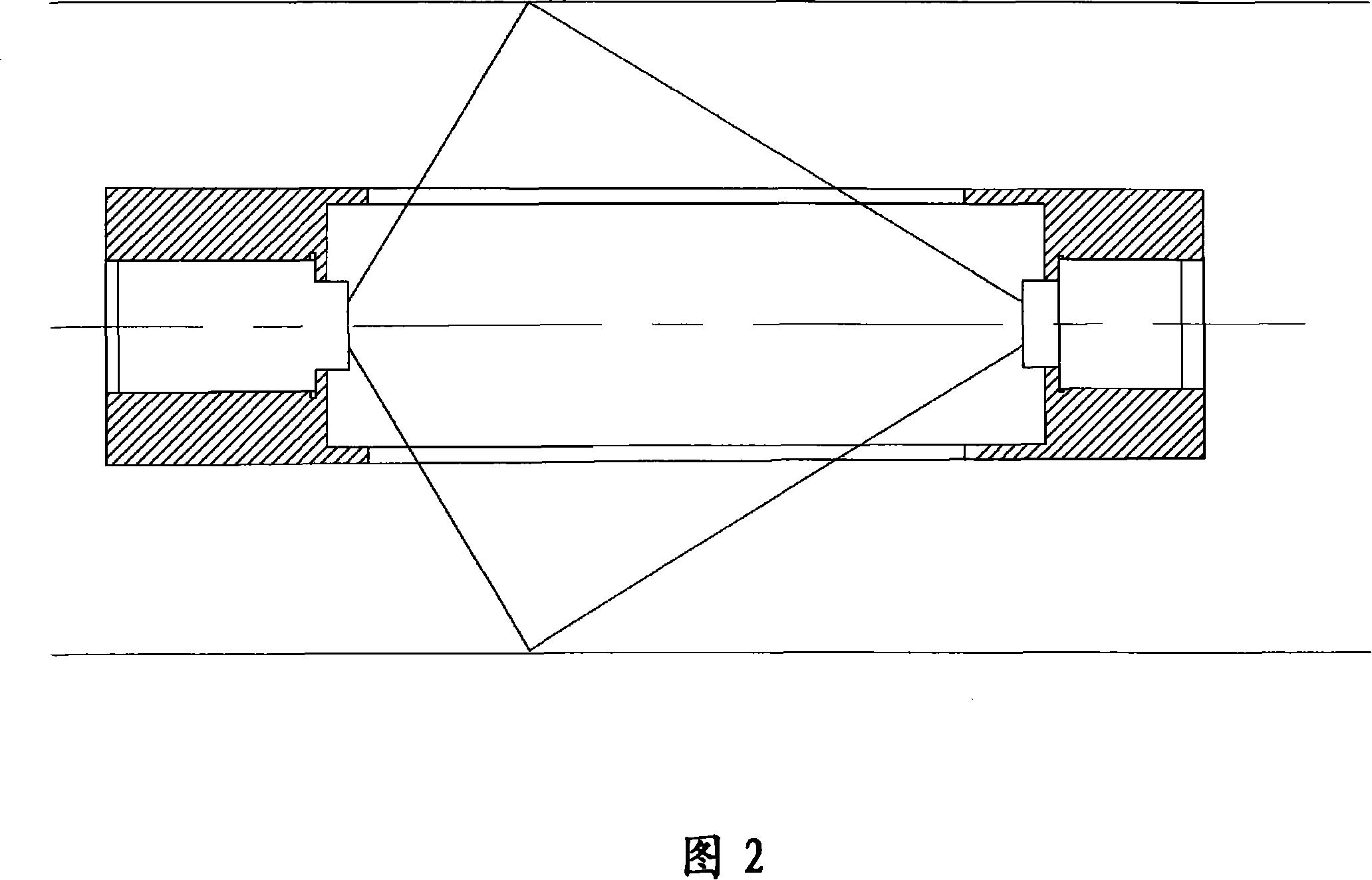

[0031] Fig. 1 is a schematic cross-sectional view of an optical hole measuring device according to Embodiment 1 of the present invention, and the cross-section passes through the central axis of the device. Fig. 2 is a schematic diagram of the working principle of the optical hole measuring device according to Embodiment 1 of the present invention.

[0032] As shown in FIG. 1 , the optical hole measuring device A has a frame 5 , a laser generator 1 as a laser light source, and a CCD camera 3 as an optical pickup device disposed in the frame 5 . In addition, the optical hole measuring device A is powered by a power source.

[0033] As shown in Figure 1, in this embodiment, the laser generator 1 is a ring laser generator capable of emitting ring-shaped laser light, and the laser beam emitted by it is in the form of outward diffusion, that is, the laser beam is in the shape of a c...

Embodiment approach 2

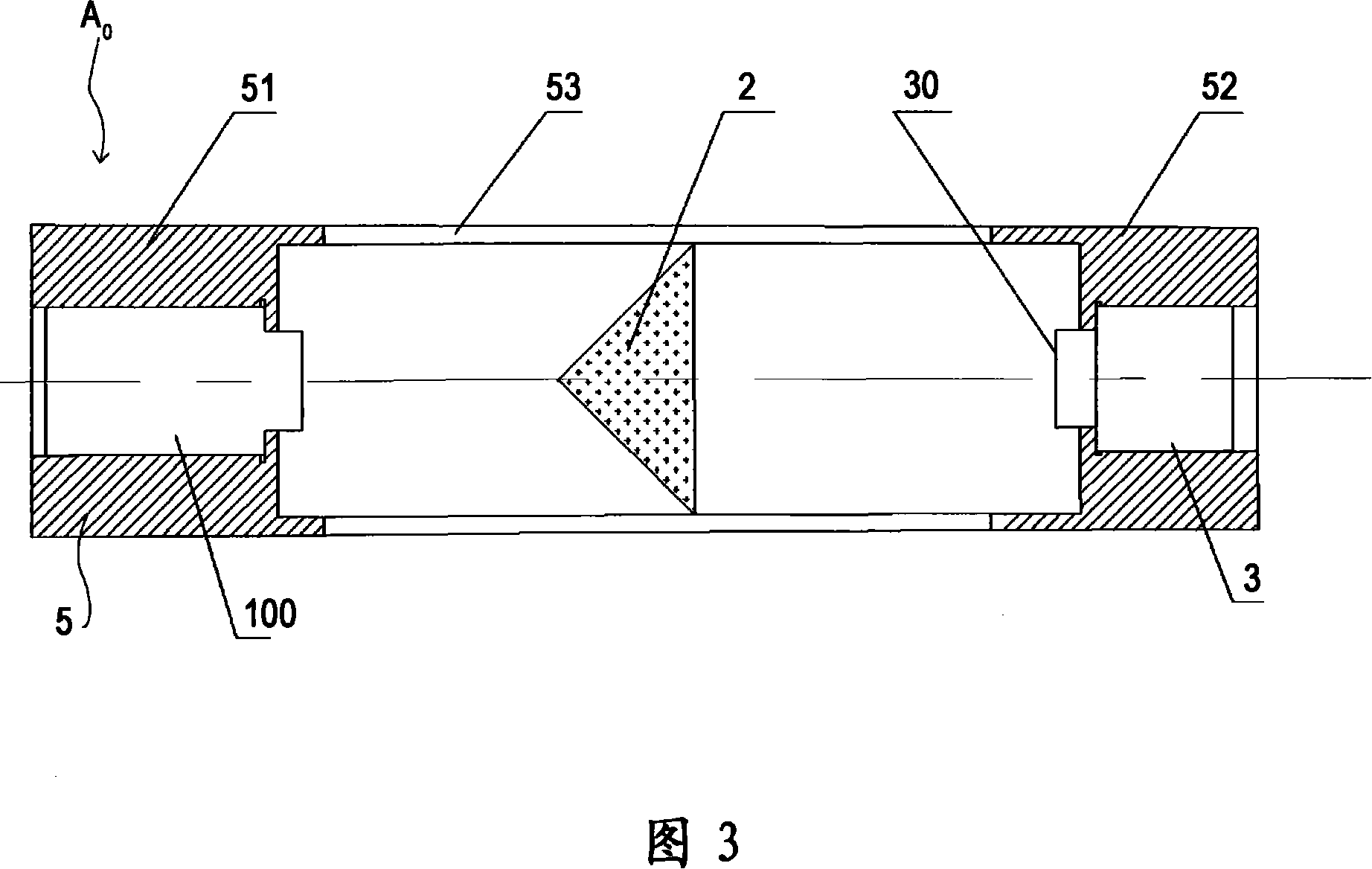

[0051] Fig. 3 is a schematic cross-sectional view of the optical hole measuring device according to Embodiment 2 of the present invention, the cross-section passing through the central axis of the device. Fig. 4 is a schematic diagram of the working principle of the optical hole measuring device according to Embodiment 2 of the present invention.

[0052] As shown in FIG. 3 and FIG. 4 , a reflective mirror 2 as a reflective member is attached to the third frame 53 , and the reflective mirror 2 has a reflective portion. Optical hole measuring device A of this embodiment 0 In the present invention, the laser generator 100 is different from Embodiment 1, and other configurations can refer to the above-mentioned embodiment, and therefore, descriptions of other parts are omitted.

[0053] In the present embodiment, reflective mirror 2 is a conical solid component, and this reflective mirror 2 is used for reflecting the laser beam that is sent by laser generator 100, therefore, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com