Method for measuring thin layers in solid state devices

A solid-state, object-based technology, applied in semiconductor/solid-state device testing/measurement, measuring devices, instruments, etc., can solve problems such as unsatisfactory technology and indistinguishable signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

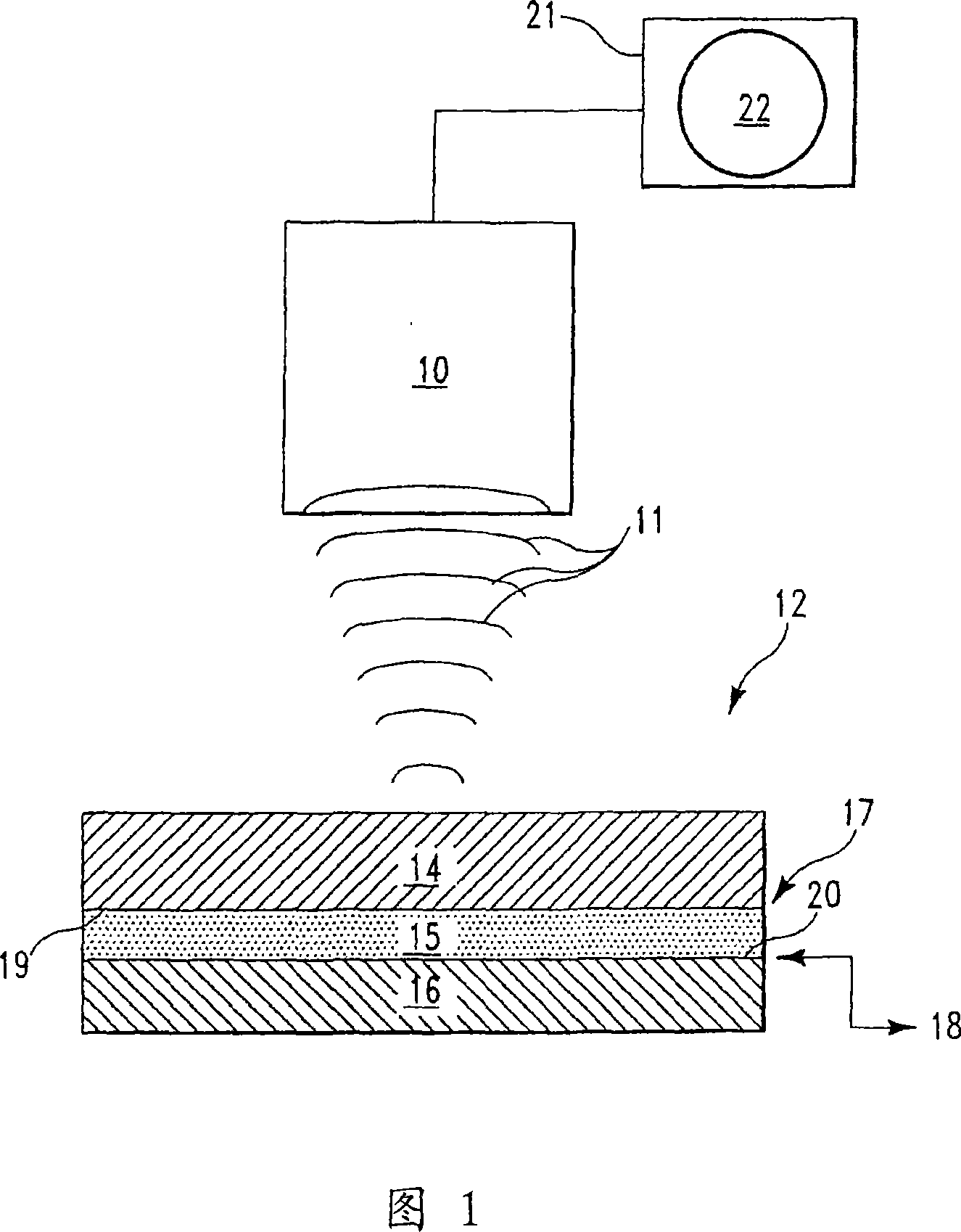

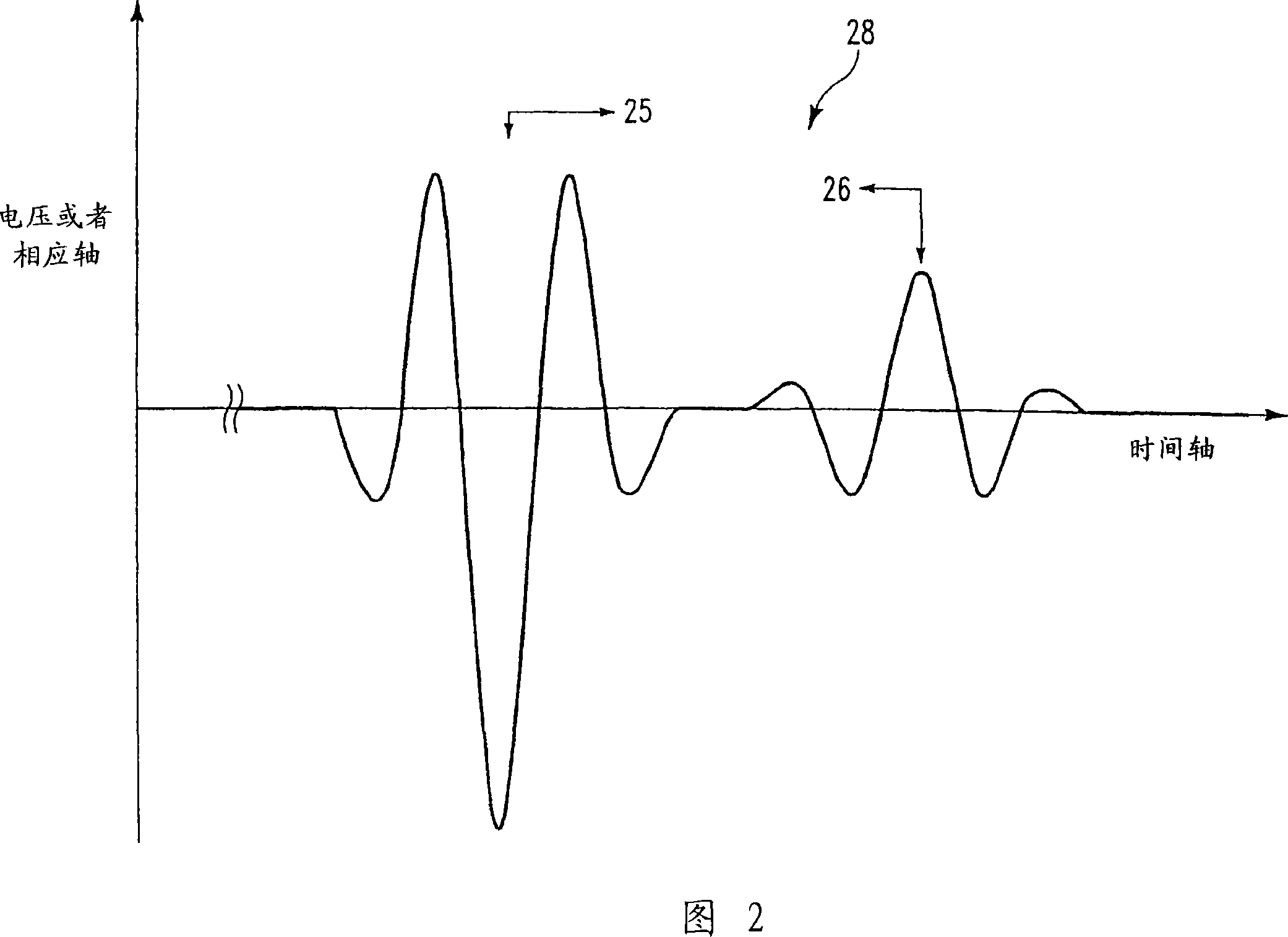

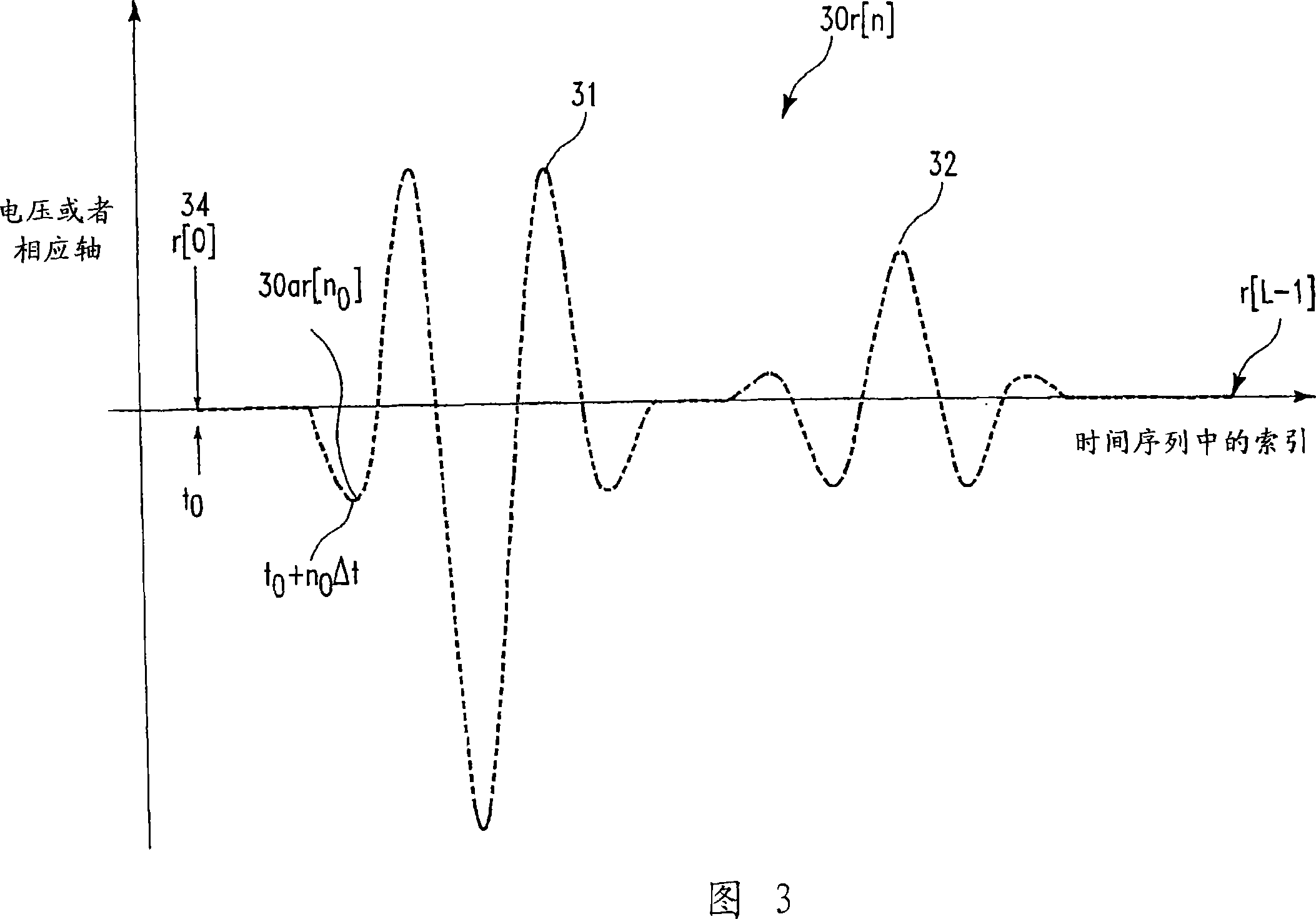

[0022] A full understanding of the features and advantages of the present invention may be better obtained by referring to the accompanying drawings, in particular: Figure 1 schematically illustrates an acoustic microscope, applying sound waves to the surface of an object comprising The middle bond layer is fixed to the first material on the second material; Figure 2 shows when a wave from the microscope of Figure 1 is applied to a device with a bond layer thick enough to produce sufficiently separated primary and secondary echoes The resulting primary and secondary echoes; Figure 3 shows the primary and secondary echoes shown in Figure 2 after these echoes have been digitized into corresponding time series; Figure 4 shows the time Figure 5 shows the primary and secondary echoes returned from the object of Figure 1 when the object contains a bonding layer whose thickness is so thin that the primary and secondary echoes overlap each other; Fig. 6 shows the primary and secondary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com