Polyamine-coated superabsorbent polymers

A superabsorbent, polymer technology for absorbent pads, coatings, bandages, etc. that addresses adverse effects, difficulty in improvement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

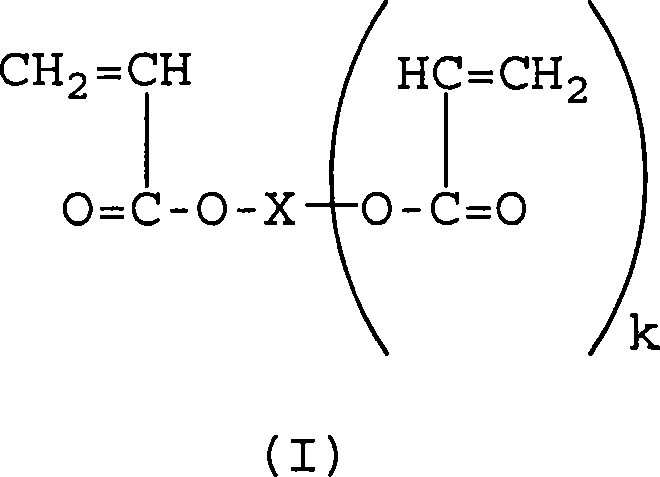

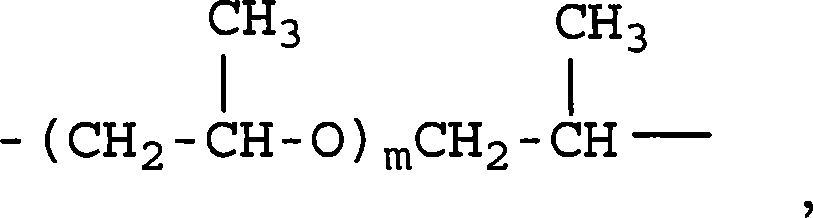

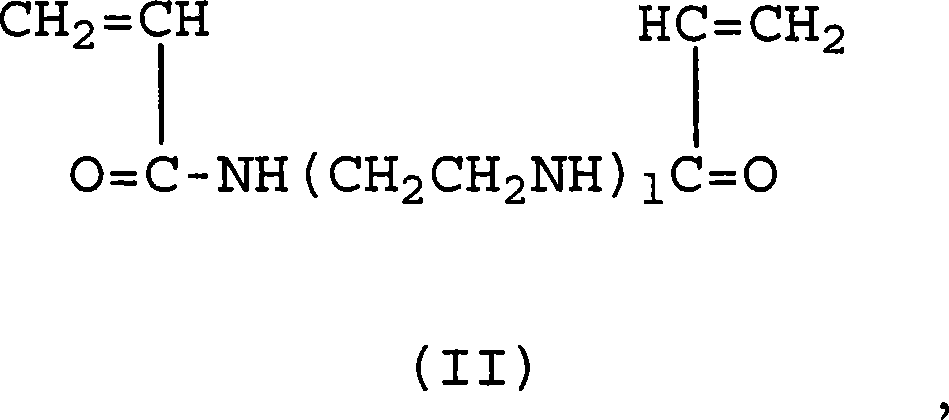

Method used

Image

Examples

Embodiment 1

[0104] base polymer 1) : CRC=30g / g, particle size distribution: 106-850μm (>850μm particle amount: 0.2%)

[0105] With coating solution 1: 3g CATIOFAST 2) VHF (polyvinylamine, 22% solids) and 2 g propylene glycol were used to coat the base polymer (40 g), followed by coating solution 2: 0.8 g deionized water, 0.8 g propylene glycol, aluminum sulfate solution (27% solids) as listed in the table below ) and 0.08g ethylene glycol diglycidyl ether (EGDGE) coating. The resulting base polymer particles were then heated in a laboratory oven at 150°C for 60 minutes to provide SAP particles of the invention.

[0106] Aluminum sulfate

the solution

CRC(g / g)

AUL0.9psi

(g / g)

0.3psiGBP

(Darcy)

>850μm

0g 3)

24.7

16.6

6

16.7%

2.2g

23.5

17.8

19

2.1%

3.1g

22.5

16.4

24

1.2%

[0107] 1) The raw material poly...

Embodiment 2

[0111] base polymer 4) : CRC=33g / g, pH=6.0, DN=74mol%, particle size distribution: 106-850μm (>850μm particle amount: 0.3%)

[0112] With coating solution 1: 3g CATIOFAST VHF (polyvinylamine, 22% solids) and 2 g propylene glycol were used to coat the base polymer (40 g), followed by coating solution 2: 0.4 g deionized water, 0.8 g propylene glycol, sodium phosphate solution (12 g in water) as listed below % solids) and 0.12 g EGDGE coating. The resulting base polymer particles were cured in a laboratory oven at 150°C for 60 minutes to provide the SAP particles of the present invention.

the solution

CRC(g / g)

AUL0.9psi

(g / g)

0.3psiGBP

(Darcy)

>850μm

0g 3)

26.3

18.6

3

18.5%

2.0g

25.9

17.9

8

3.4%

4.2g

25.6

17.2

10

1.6%

[0114] 4) Sodium polyacrylate

[0115] Ex...

Embodiment 3

[0117] Poly(sodium acrylate) superabsorbent particles (100 parts) with CRC=25.5 g / g and DN=74% were mixed with 7.5 parts containing 26.7% water, 25.7% propylene glycol in a Lödige M5 mixer operating at 300 rpm , 44.9% alum solution F (27% aluminum sulfate) and 1.7% EGDGE solution. The resulting granules were dried at 130° C. for 1 hour. These granules were further treated with 8 parts of a solution containing 62.3% ultrafiltered 50K polyvinylamine (27 wt% PVAm), 37.4% propylene glycol and 0.25% EGDGE in a Lödige M5 mixer operating at 300 rpm. The resulting granules were again dried at 130°C for 1 hour to provide SAP granules with CRC = 20.6 g / g and 0.3 GBP = 9.2 Darcy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water solubility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com