Yellow-green halimasch fibrinolytic enzyme and production method thereof

A technology of Armillaria chrysanthemum and its production method, applied in the field of Armillaria chrysogenum and its production and preparation, to achieve the effect of easy extraction and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

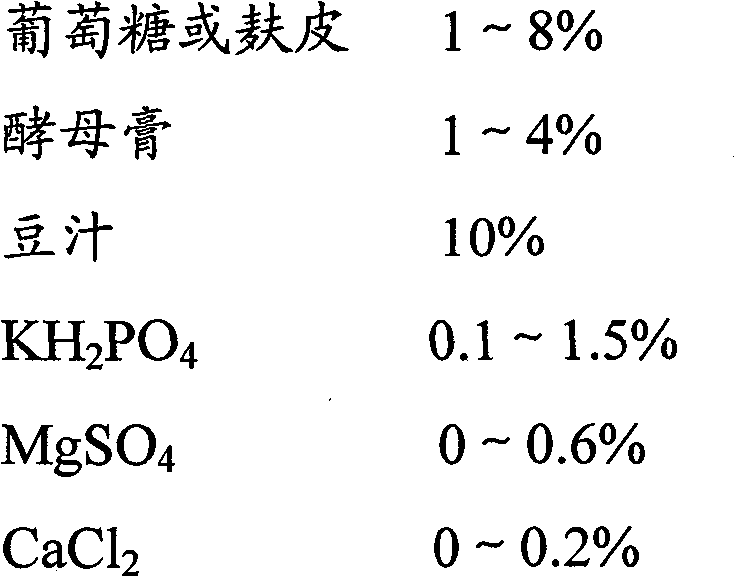

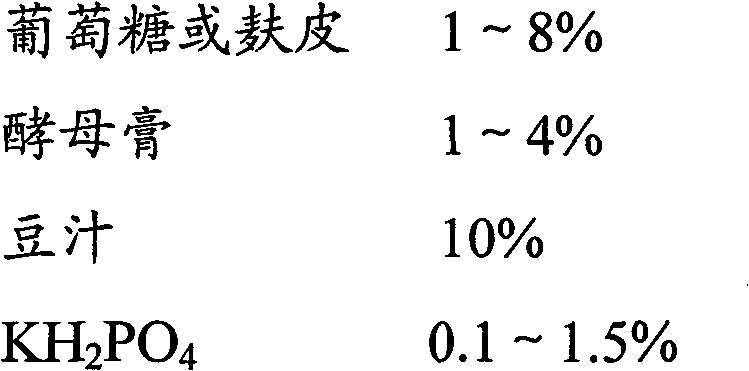

[0037] Medium, culture method and extraction:

[0038] The strains were stored on a slant in PDA medium. First, the strains were cultured at 23° C. for 72 hours, and then inoculated on the liquid fermentation medium.

[0039] The liquid fermentation medium contains 2% glucose, 2% yeast extract, 10% soybean juice (preparation method: soak 10% soybeans for 24 hours, simmer for 30 minutes, and extract the juice), KH 2 PO 4 1%, MgSO 4 0.45%, pH 4.

[0040] Inoculum size 1×10 8 spores / ml, the fermentation temperature is 28°C, the shaker speed is 140r / min, and the maximum enzyme activity obtained is 310IU / ml after culturing for 120 hours.

[0041] Rough purification of enzymes: The fermented liquid is subjected to high-speed refrigerated centrifugation at a speed of 12000r / min and a temperature of 4°C to remove the bacteria to obtain supernatants, which are respectively 45% and 80% ammonium sulfate solutions by mass Carry out segmental salting-out, and dissolve the precipitat...

Embodiment 2

[0044] The strains were stored on a slant in PDA medium. First, the strains were cultured at 23° C. for 72 hours, and then inoculated on the liquid fermentation medium.

[0045] The liquid fermentation medium contains 2% bran, 2% yeast extract, 10% soybean juice (preparation method: soak 10% soybeans for 24 hours, simmer for 30 minutes, filter to obtain juice), KH 2 PO 4 1%, MgSO 4 0.45%, 0.1% CaCl 2 , pH 4. Inoculum size 1×10 8 spores / ml, the fermentation temperature is 28°C, the shaker speed is 140r / min, and the maximum enzyme activity obtained after 120 hours of fermentation is 450IU / ml.

[0046] According to the rough purification of enzyme in embodiment 1 and the fine purification method of enzyme, obtain the higher Armillaria chrysanthemum fibrinolytic enzyme of enzyme activity, through SDS-PAGE analysis, its apparent molecular size is 26KDa; The ratio of this enzyme The activity is 40000IU / mg protein.

Embodiment 3

[0048] The strains were stored on a slant in PDA medium. First, the strains were cultured at 23° C. for 72 hours, and then inoculated on the liquid fermentation medium.

[0049] The liquid fermentation medium contains 5% bran, 1% yeast extract, 10% soybean juice (preparation method: soak 10% soybeans for 24 hours, simmer for 30 minutes, filter to obtain juice), KH 2 PO 4 1%, MgSO 4 0.5%, 0.1% CaCl 2 , pH 4. The inoculum size is 1×10 8 spores / ml, the fermentation temperature is 28°C, the shaker rotation speed is 140r / min, and the maximum enzyme activity obtained by fermentation for 120 hours is 517IU / ml.

[0050] According to the rough purification of enzyme in embodiment 1 and the fine purification method of enzyme, obtain the higher Armillaria chrysanthemum fibrinolytic enzyme of enzyme activity, through SDS-PAGE analysis, its apparent molecular size is 26KDa; The ratio of this enzyme The activity is 50000IU / mg protein.

[0051] Example 3

[0052] The strains were st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com