Direct freezing type refrigerator capable of enhancing thermal discharging efficiency of condensator

A technology for condensers and refrigerators, which is used in household refrigeration devices, lighting and heating equipment, household appliances, etc., can solve the problems of reducing the efficiency of refrigeration cycles, increasing the amount of refrigerant filling, and disturbing the liquid refrigerant, so as to reduce the length of pipes and reduce the size of pipes. length, noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

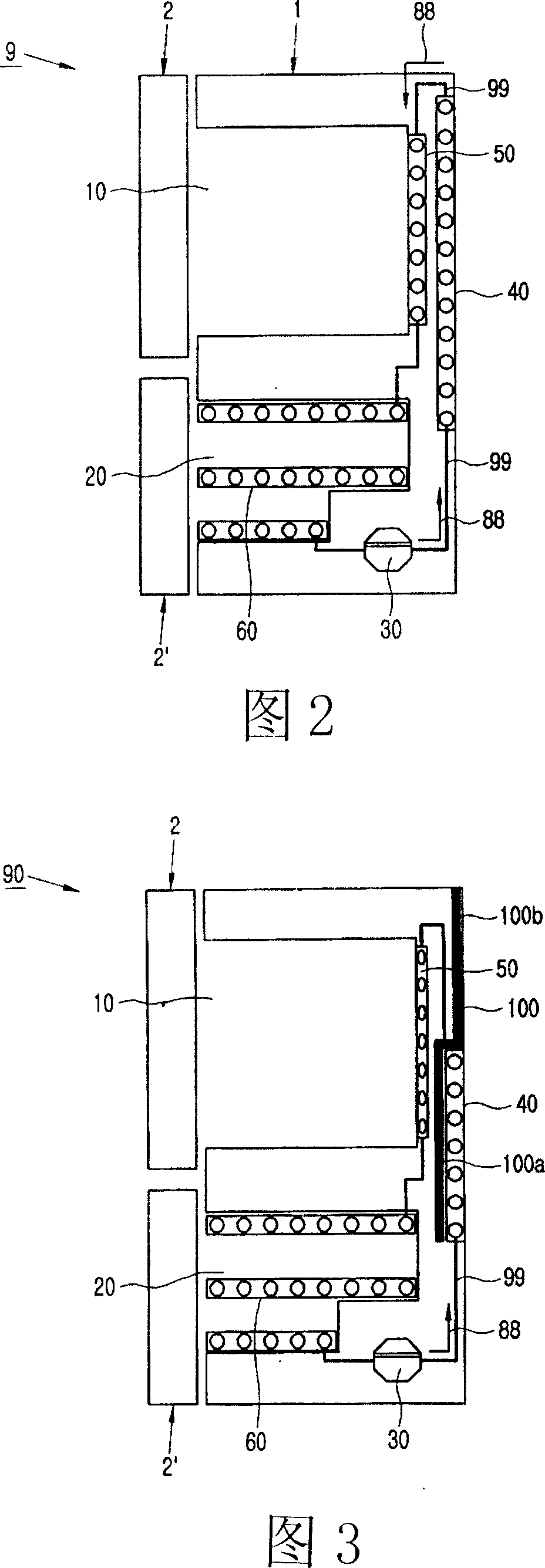

[0030] As shown in FIG. 3 , a direct cooling refrigerator 90 according to an embodiment of the present invention includes the following parts: a refrigerator casing 1 forming a refrigerating chamber 10 and a freezing chamber 20; The compressor 30 at the bottom of the above-mentioned casing 1; the condenser 40 that receives the compressed refrigerant supplied in the direction of reference numeral 88 in the drawing along the refrigerant flow path 99, releases heat to the surroundings, and condenses the refrigerant; The refrigerant absorbs the surrounding heat and cools the refrigerator compartment 10. The first evaporator 50 is formed in close contact with the rear of the refrigerator compartment 10; it is formed between the shelves of the freezer compartment 20 and is used to evaporate the first evaporator 50 described above. The refrigerant of the evaporator 50 and the second evaporator 60 that cools the freezer compartment 20; the surface is in contact with the surface opposit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com