Mechanical caging device for on-off switch and interlocking mechanism for control cabinet door of high-voltage electric main control cabinet

A mechanical locking, high-voltage electrical technology, applied in the direction of electric switches, air switch parts, electrical components, etc., can solve the problems of unopenable cabinet doors, poor reliability, complicated wiring, etc., to ensure safety, trouble-free installation, and structural simplified effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable examiners, especially the public, to further understand the structural features and beneficial effects of the present invention, the specific implementation of the present invention is described in detail as follows in conjunction with the drawings and examples:

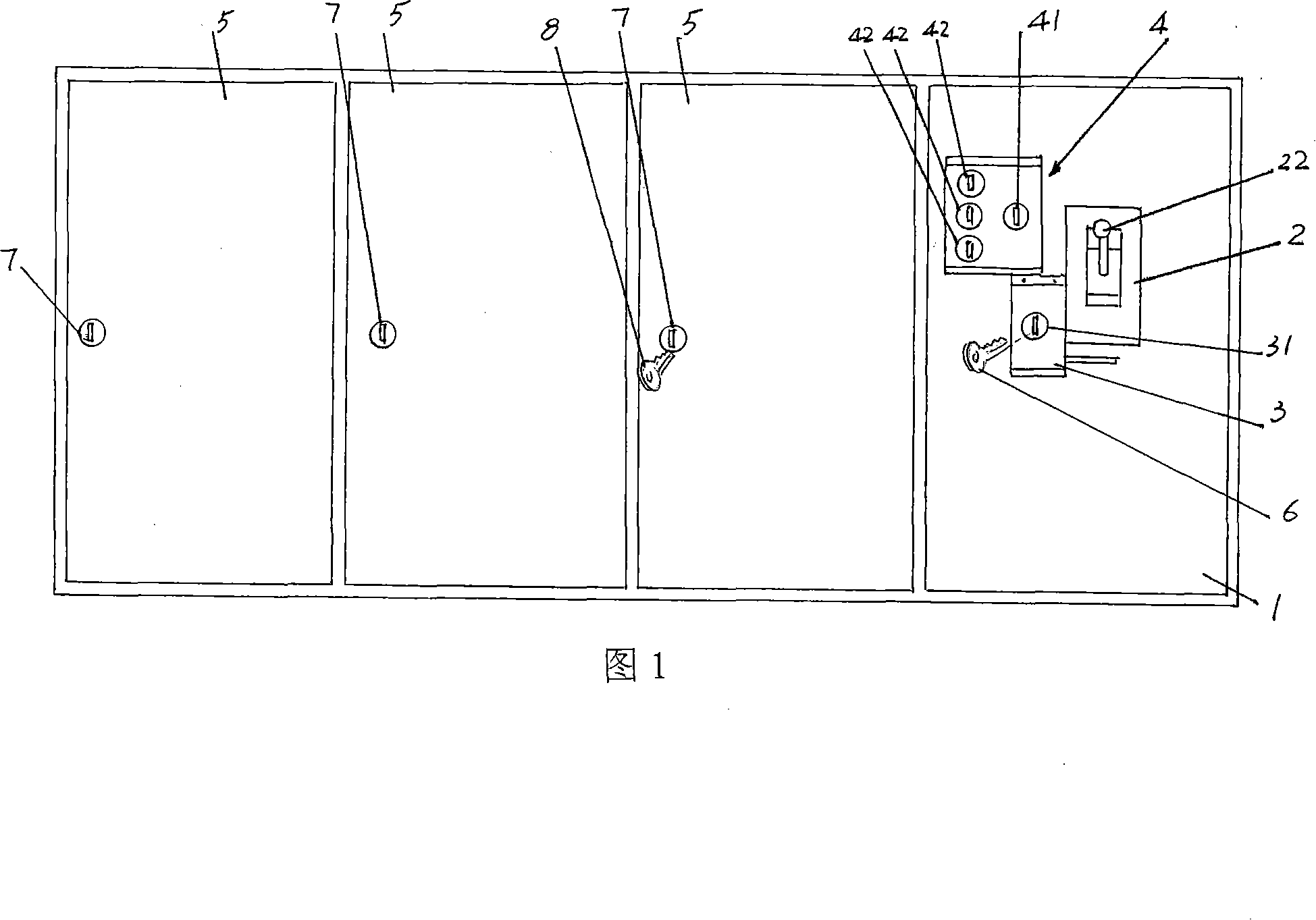

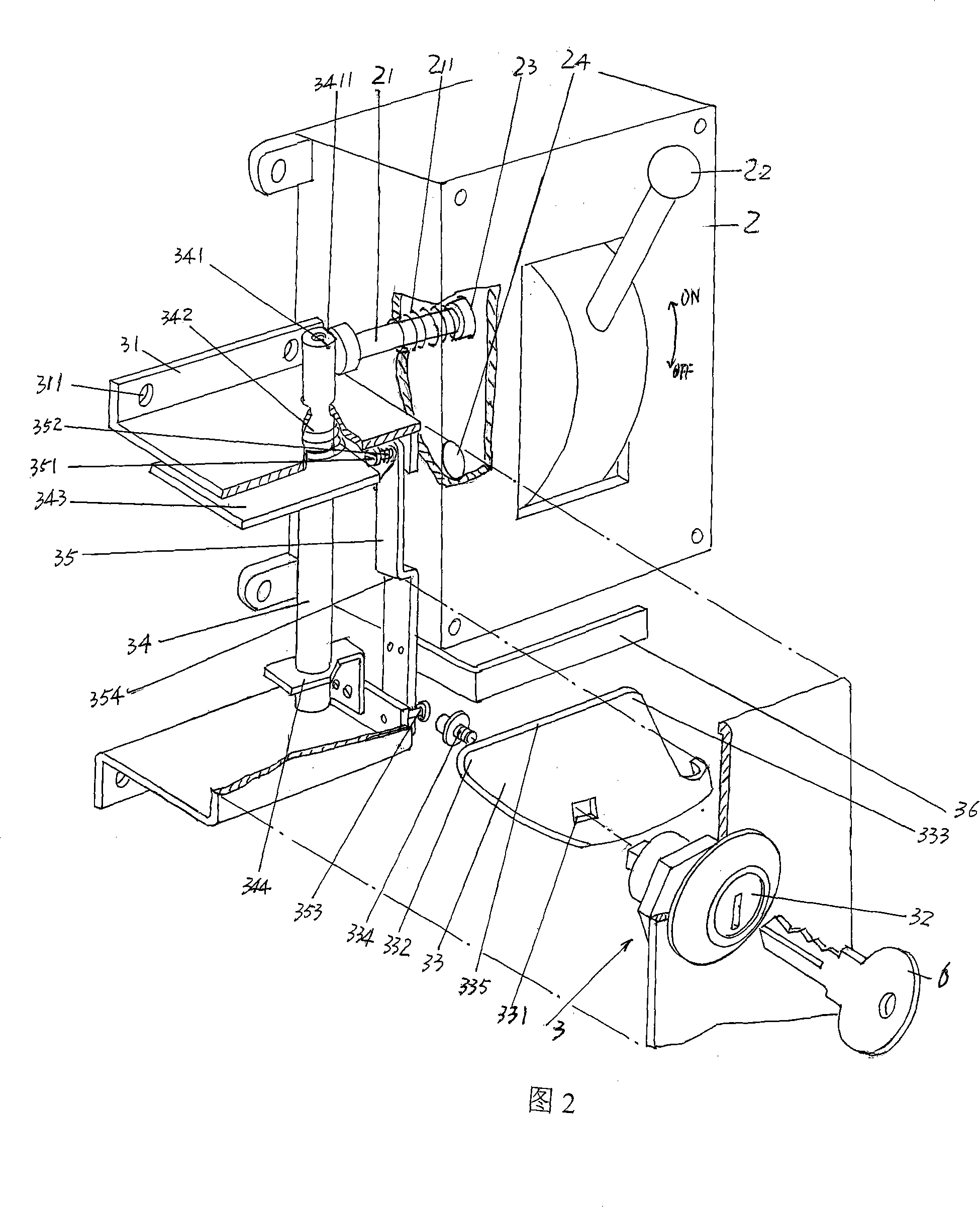

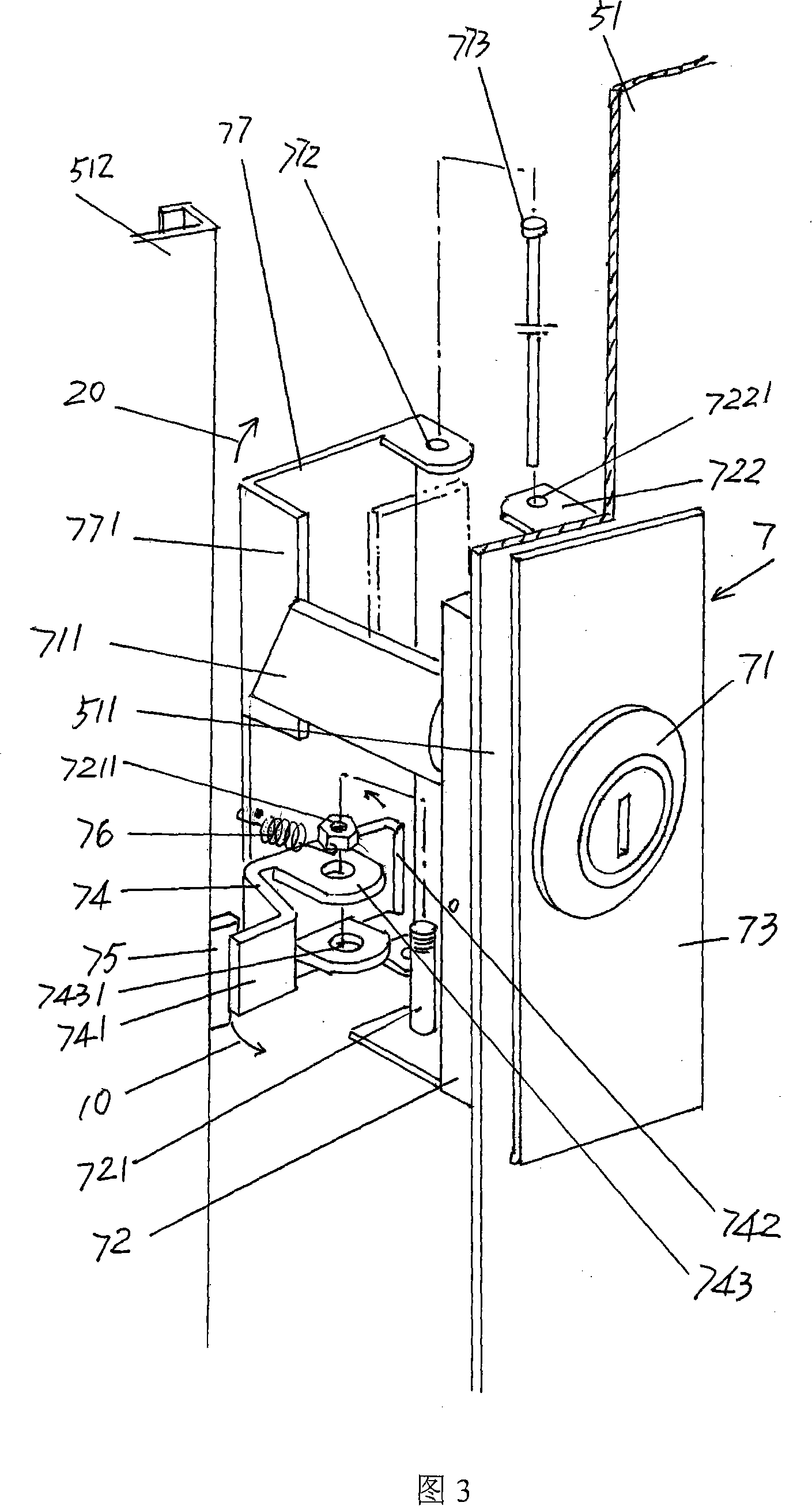

[0021] Please refer to Fig. 1, as a certain embodiment that is not specifically limited, the applicant has provided a set of main control cabinet cabinet body 1, and this main control cabinet cabinet body 1 is equipped with three sets of sub-control cabinets 5, three sets of sub-control cabinets 5 The control cabinet 5 is used to respond to the voltage (energy) distributed by the main control cabinet 1. If the main control cabinet 1 is defined as an upstream high-voltage electrical cabinet, then the sub-control cabinet 5 can be defined as a downstream high-voltage electrical cabinet. Install the first mechanical locking device 3 at the opening and closing switch 2 adjacent to the main control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com