Mascara brush

An eyelash brush and eyelash technology, which is applied in the field of eyelash brushes, can solve the problems of not being able to comb the eyelashes well, the teeth of the plates cannot be close together, and the eyelashes stick together, etc., and achieve the effect of low cost, simple manufacture, and good curling degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The mascara brush of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] The accompanying drawings of the present invention are illustrated to make the above and other objects, features, advantages and embodiments of the present invention more comprehensible, but the present invention is not limited to the forms in these drawings.

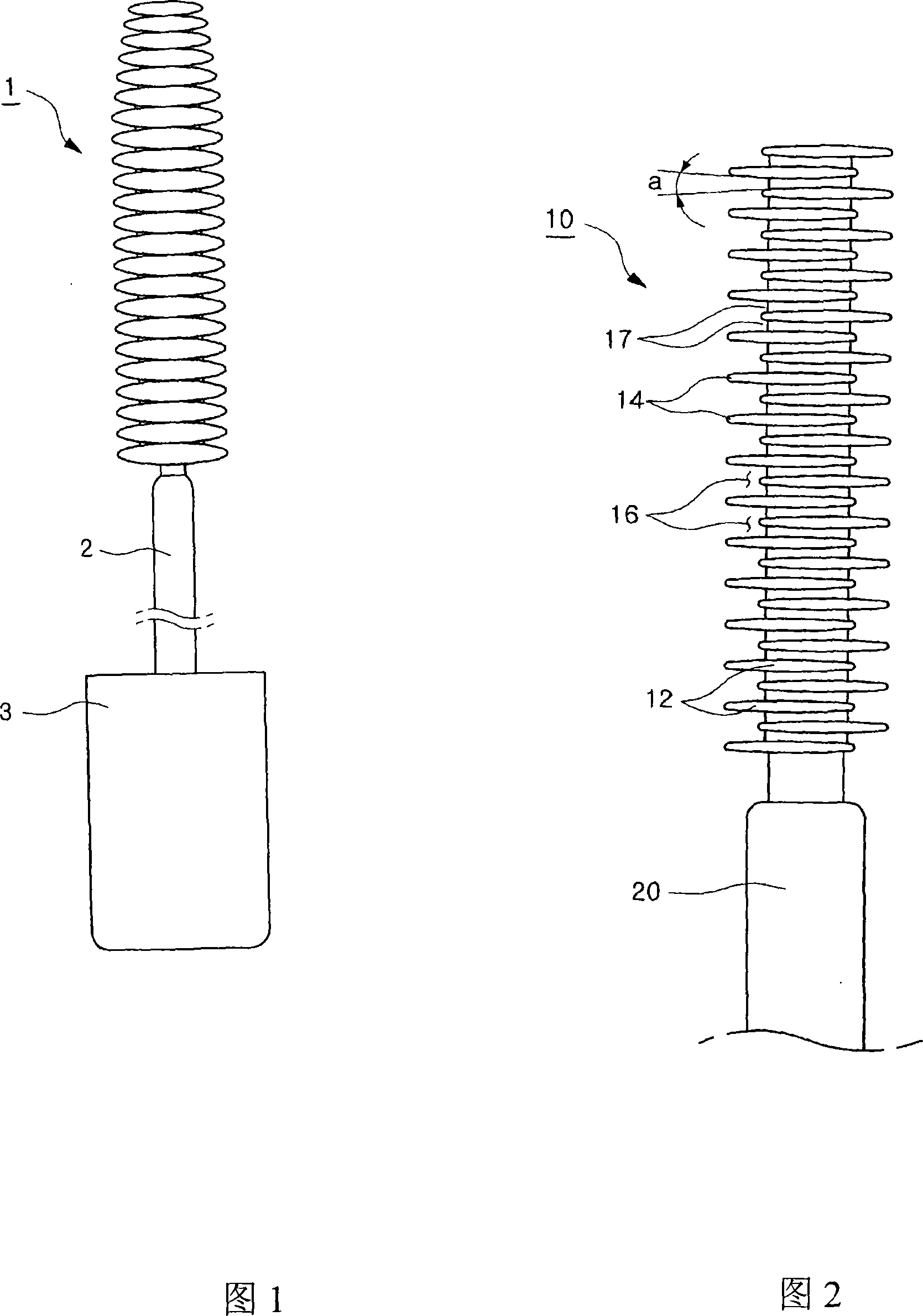

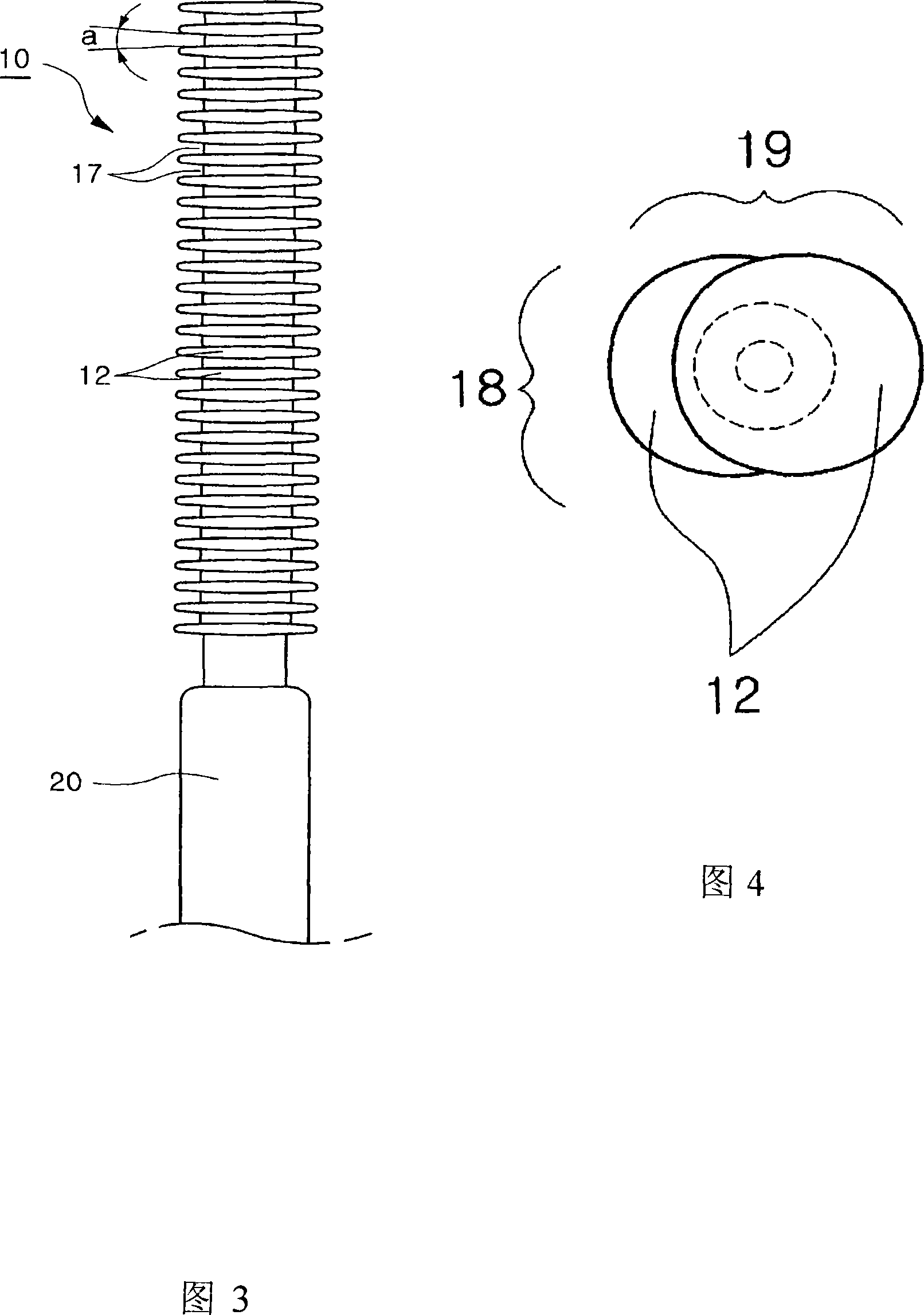

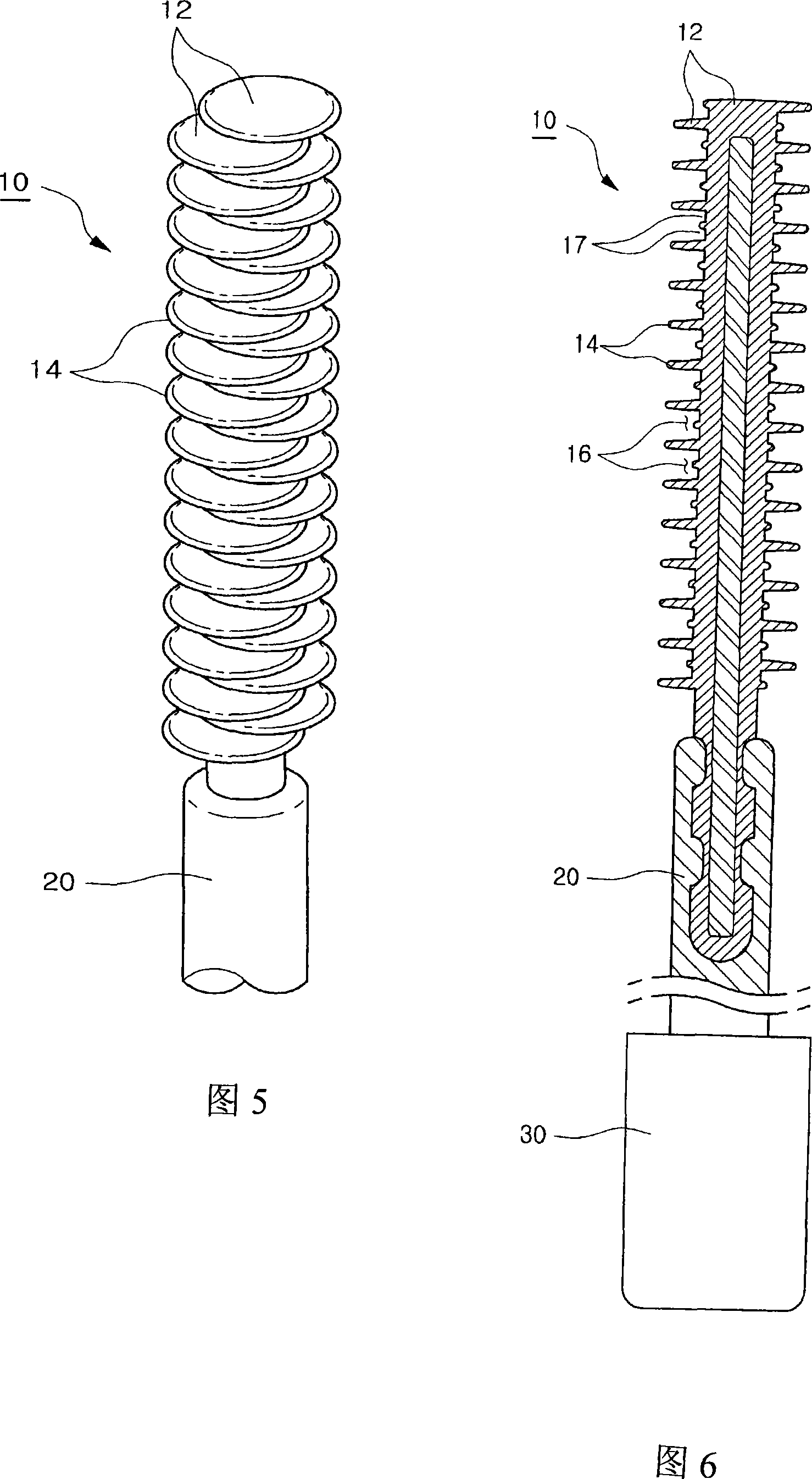

[0024] Fig. 2 is the front view of the mascara brush according to one embodiment of the present invention, Fig. 3 is the side view of the mascara brush according to one embodiment of the present invention, Fig. 4 is the plane view of the mascara brush according to one embodiment of the present invention, FIG. 5 is a perspective view of a mascara brush according to one embodiment of the present invention, and FIG. 6 is a vertical sectional view of the mascara brush according to one embodiment of the present invention.

[0025] As shown in the figure, the present invention provides a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com