Powder feeder for manufacturing function gradient element or material

A functional gradient, powder feeder technology, applied in metal material coating process, conveyor, mechanical conveyor, etc., can solve the problems of difficult control of powder feeding amount, screw stuck, poor powder discharge, etc., to achieve powder feeding The effect of continuous and easy control, increasing conveying distance and long powder feeding distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

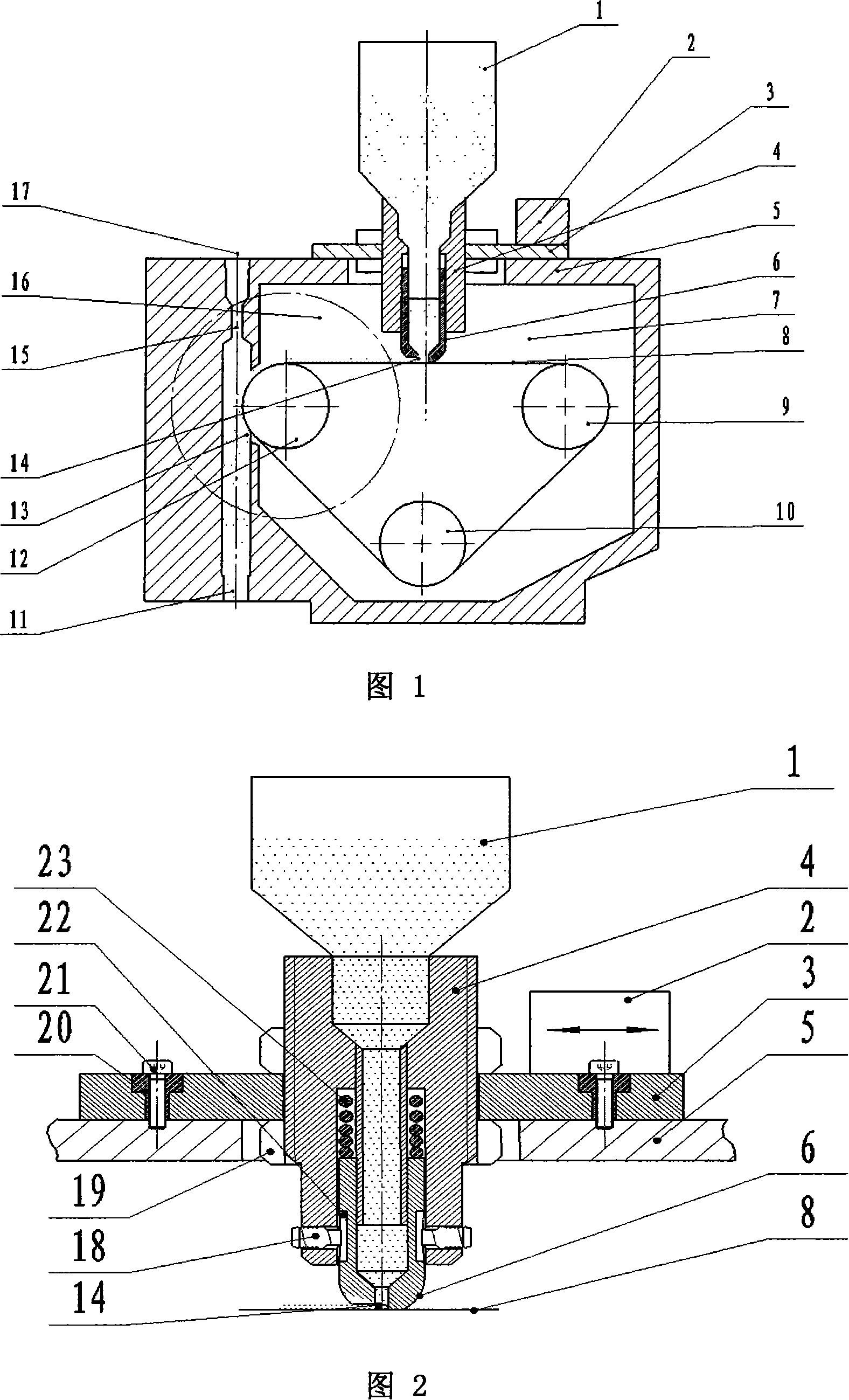

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0017] As shown in Fig. 1, driving wheel 12, driven wheel 9, tension pulley 10 and synchronous powder feeding belt 8 are installed in the powder feeding cavity 7 of housing 5 of the present invention, and synchronous powder feeding belt 8 is composed of driving wheel 12 and driven wheel Driven by 9 and tensioned by the tensioning wheel 10, there is a powder feeding gap 13 on one side of the powder feeding chamber 7, which communicates with the air supply and powder outlet channel on the side of the housing; the opening on the air supply and powder outlet channel is the powder feeding gas inlet 17 1. The lower opening is the powder outlet 11, and the inner diameter of a part of the upper section of the air supply and powder outlet channel is smaller than the inner diameter of other parts, forming a powder delivery gas acceleration hole 15.

[0018] As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com