Swelling type screen pipe suspension method and swelling type screen pipe hanger

An expansion type and hanger technology, which is applied in earth-moving drilling, fluid production, wellbore/well components, etc., can solve the problems of many times of drilling, inability to establish circulation, aggravating oil layer pollution, etc., saving construction costs and improving Completion efficiency and the effect of improving recovery value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: construction process:

[0037] A. Run the screen completion string into the wellbore

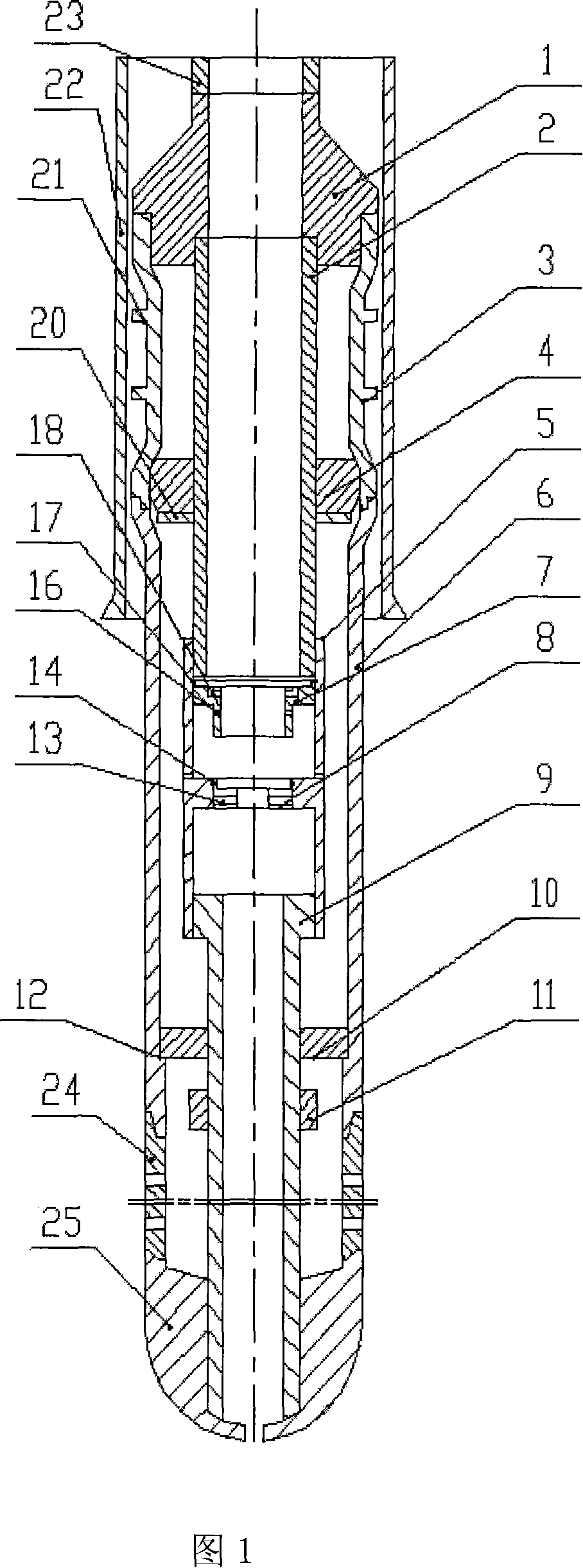

[0038] Refer to accompanying drawing 1. Run the screen completion string into the wellbore casing and lower it to the predetermined position. The structure of the screen completion string is as follows from bottom to top: the lower end is the flushing seal and the floating shoe 25, and the upper part of the flushing seal and the floating shoe 25 is connected to the screen string 24. The upper part of the screen string 24 is connected to the expandable screen hanger, and the upper part of the expandable screen hanger is connected to the drill string 23 .

[0039] B. Inject drilling fluid

[0040] When the screen completion string is lowered to the design position, the drilling fluid is injected into the screen completion string, and the original drilling fluid between the screen and the open hole is replaced by circulation, and then the drilling fluid injection is stop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com