Engine with decompression device

A decompression device, engine technology, applied in the direction of engine components, machine/engine, engine cooling, etc., to achieve the effect of suppressing increase, realizing miniaturization, and realizing the number of assembly processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

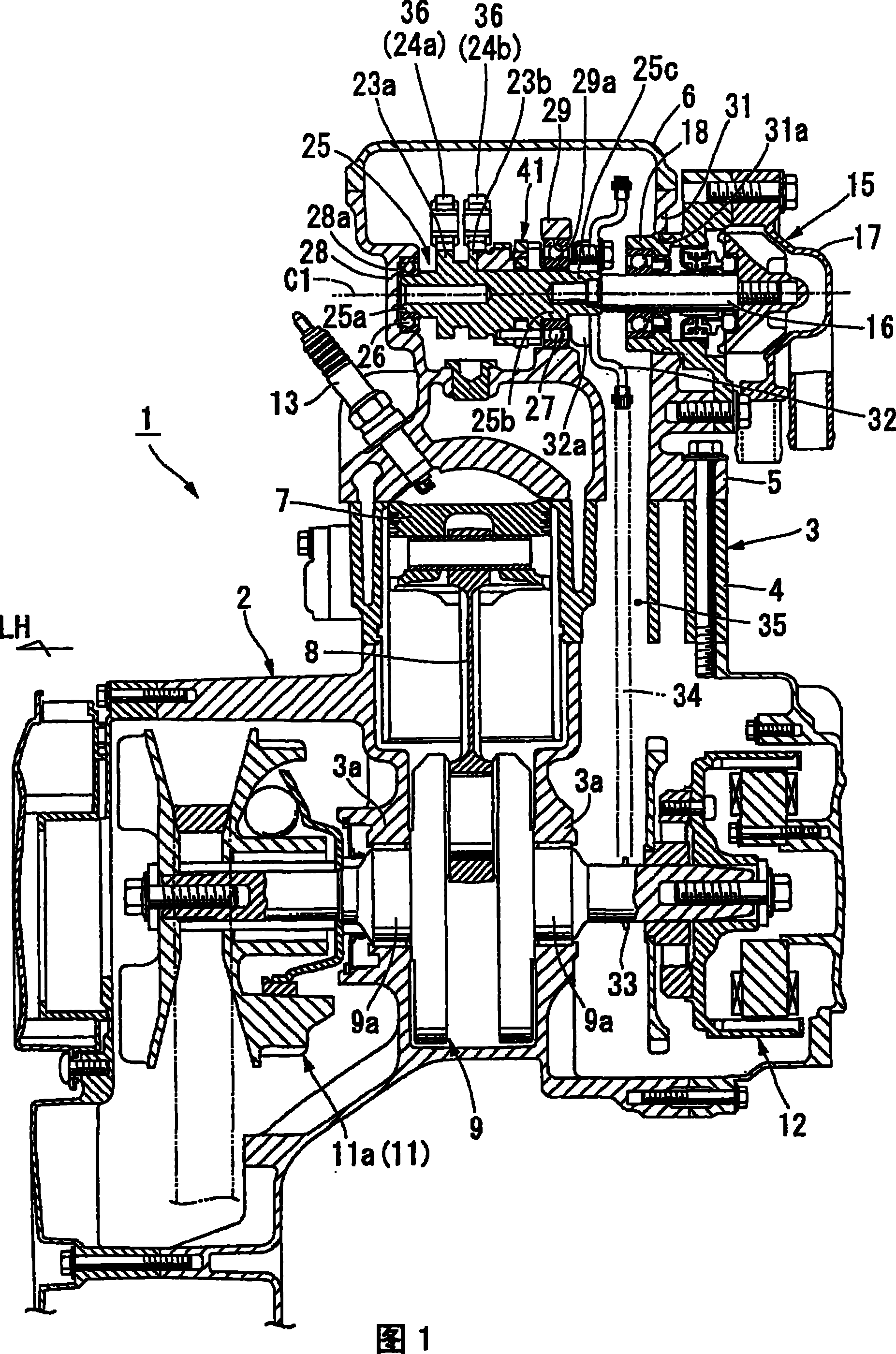

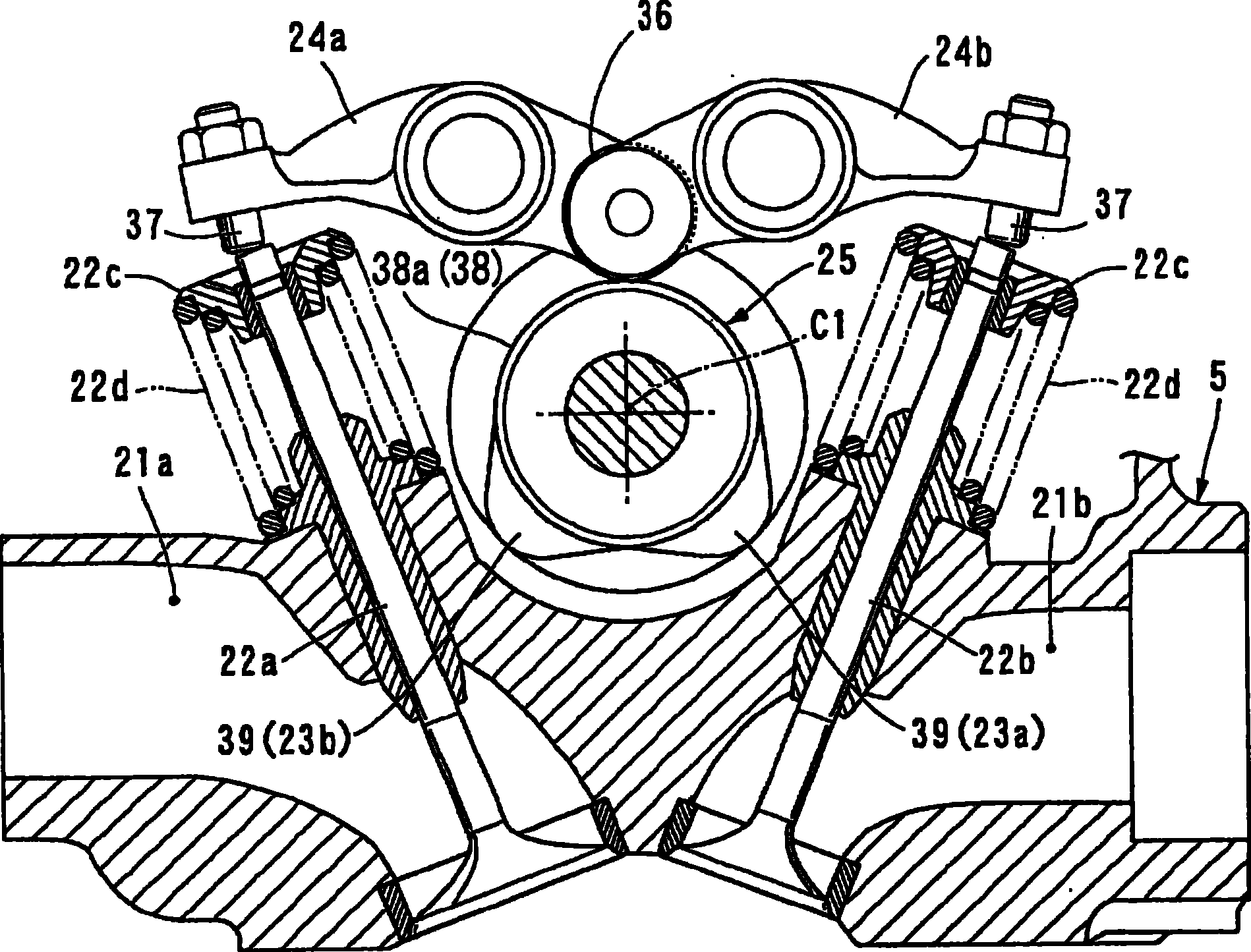

[0038] figure 1 The shown engine 1 is used, for example, as a prime mover of a vehicle such as a motorcycle, and is constituted by a water-cooled four-cycle single-cylinder engine.

[0039] The cylinder unit 3 protrudes from the crankcase 2 of the engine 1 . The cylinder unit 3 is mainly composed of a cylinder body 4 attached to the crankcase 2 , a cylinder head 5 attached to the front end of the cylinder body 4 , and a head cover 6 attached to the front end of the cylinder head 5 . Here, the arrow LH in the figure indicates the left side.

[0040] A piston 7 is reciprocally fitted inside the cylinder body 4 . Piston 7 is connected to crankshaft 9 via connecting rod 8 . Left and right journals 9 a of the crankshaft 9 are rotatably supported by left and right bearing portions 3 a of the crankcase 2 .

[0041] The rotational power of the crankshaft 9 is output via, for example, a belt-type continuously variable transmission mechanism 11 . Further, a drive pulley 11 a of th...

Embodiment 2

[0089] Next, regarding the second embodiment of the present invention, refer to Figure 8-12 Be explained.

[0090] The main difference between the engine 101 (decompression device 141) of this embodiment and the above-mentioned first embodiment is that the decompression counterweight 142 is provided with the above-mentioned locking mechanism on the side opposite to the counterweight part 142c sandwiching the rotating shaft 148. For the pin 54, the same reference numerals are assigned to the same parts as those in the above-mentioned embodiment, and the description thereof will be omitted.

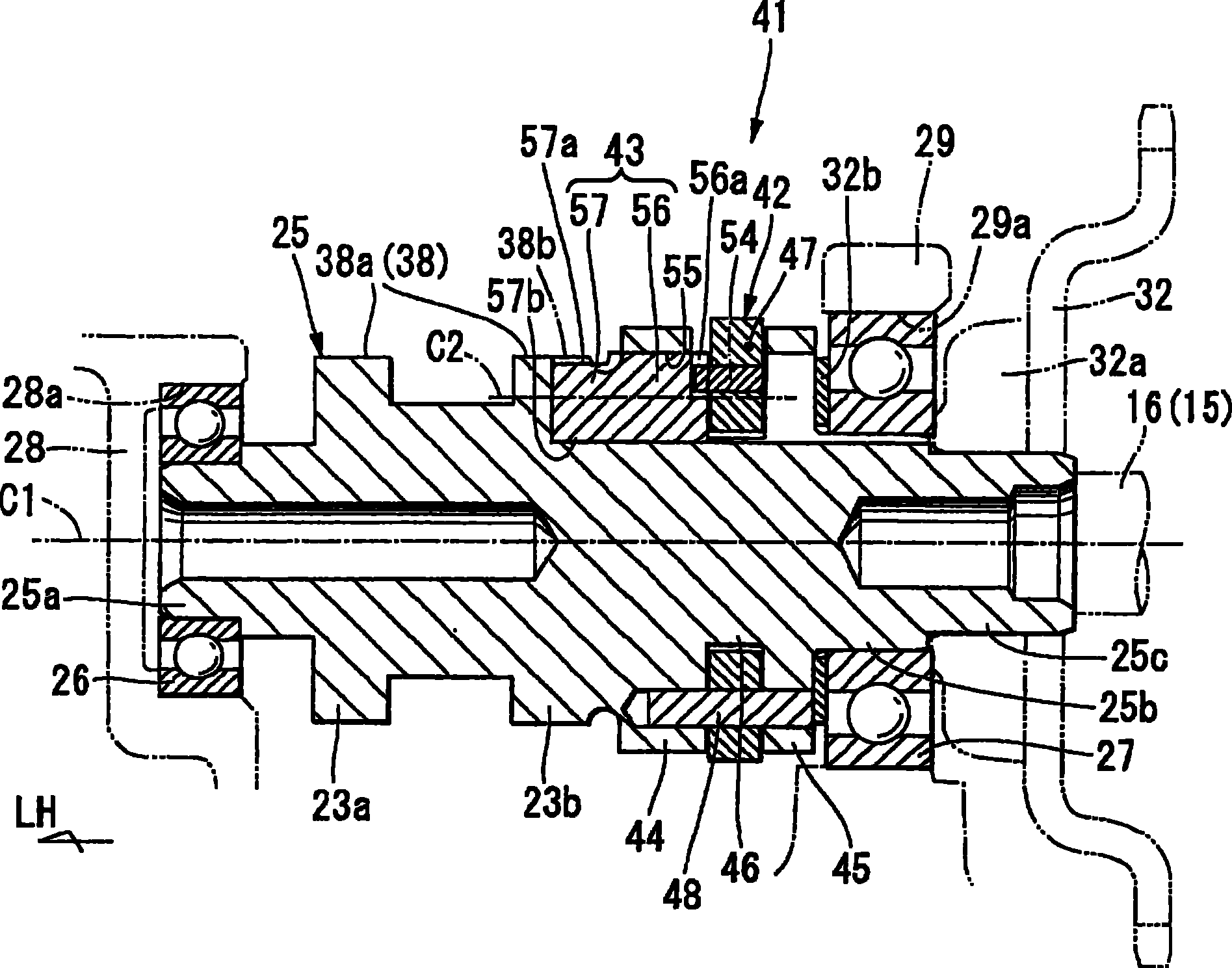

[0091] Figure 8The camshaft 125 shown has an axis C1' along the left-right direction, and its right end (right journal 25b) is rotatably supported by a right bearing support portion of the right inner wall 29 of the cylinder head 5 via a right ball bearing 27. 29a, the left end portion (left journal 125a) is rotatably directly supported by the left journal support portion 128a inside th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com