A power generation device based on magnetic flow body

A magnetic fluid power generation and electrode technology, applied in electromechanical devices, electrical components, etc., can solve the problems of materials and manufacturing difficulties, and achieve the effects of fast startup, improved efficiency, and convenient load connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

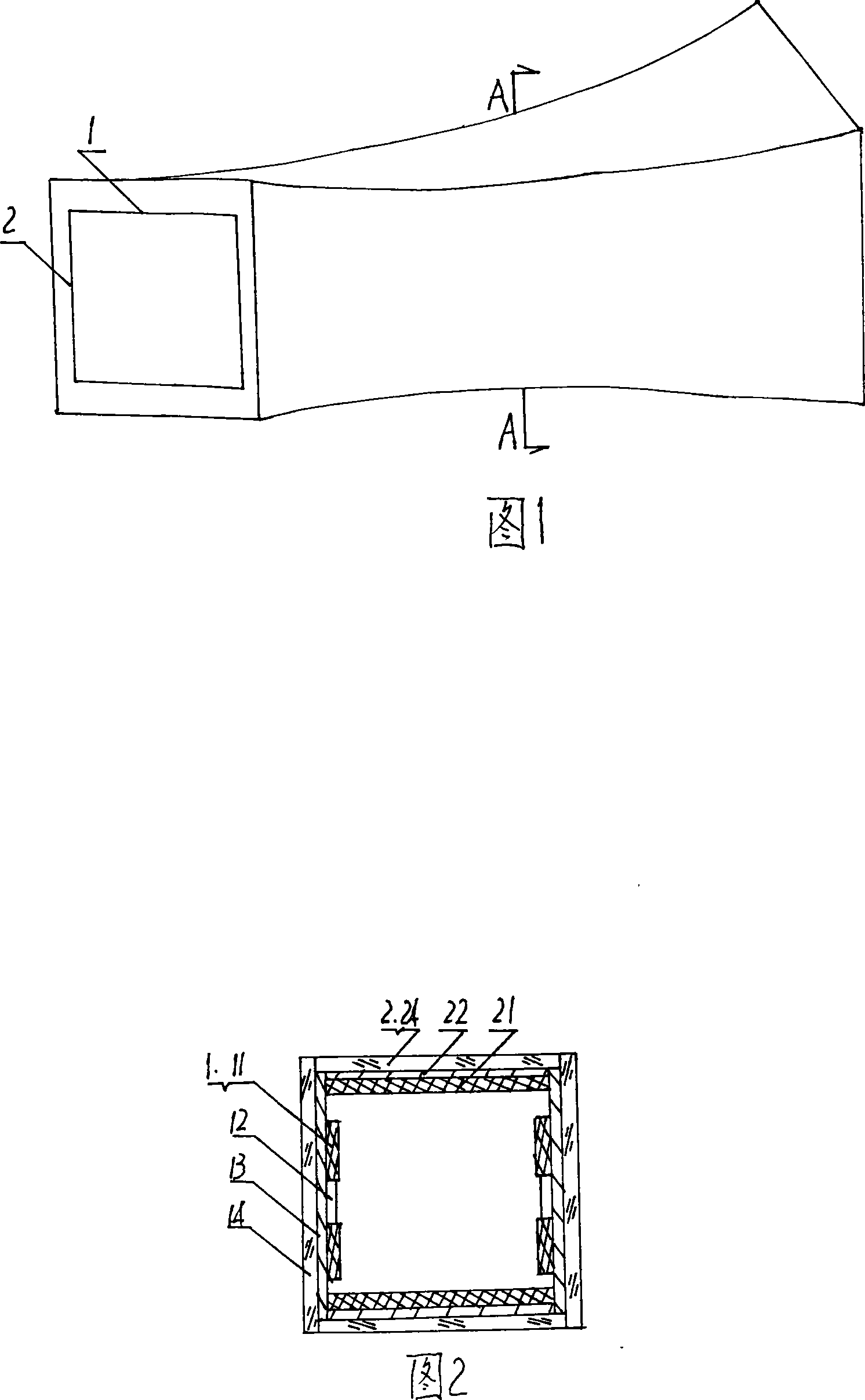

[0015] As shown in Figures 1 and 2, a magnetic fluid power generation device consists of two opposing electrode walls 1 and two opposing magnetic pole walls 2 with opposite polarities to form a box-shaped channel with a square cross-section. The channel is a linear longitudinal expansion channel, the inner surface of the channel entrance is 100mm×100mm, the inner surface of the outlet is 120mm×120mm, the wall thickness is 20mm, and the channel length is 400mm. The electrode wall is composed of an electrode 11, a copper plate 12 connected to the electrode and a glass fiber reinforced plastic 14 bonded to the copper plate from the inside to the outside. 24 electrodes are installed on both sides of the electrode wall. The electrode is in the shape of a square plate with a size of 18mm×18mm. The electrode material is graphite electrode, which does not need to be cooled, and the electrode voltage drop is small. A 2 mm thick boron nitride sheet 13 is embedded between adjacent elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com