Recycling method for waste lithium ion battery

A lithium-ion battery and waste technology, which is applied in the field of lithium-ion battery recycling and processing, can solve problems such as nickel-cobalt lithium manganese oxide positive electrode materials and lithium carbonate that have not been seen yet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

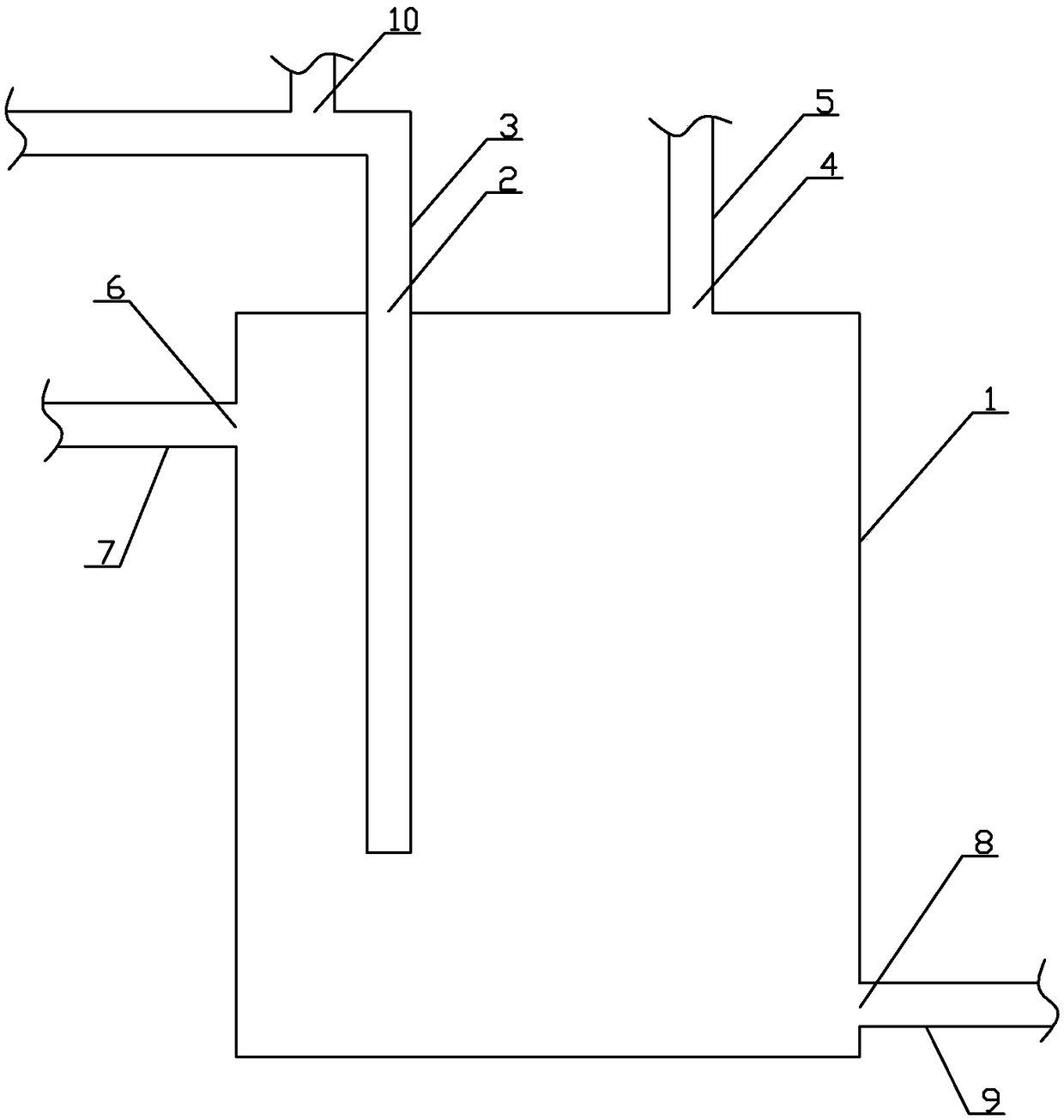

Image

Examples

Embodiment 1

[0053] (1) Take the waste nickel-cobalt manganese oxide lithium battery and the waste lithium iron phosphate battery, discharge according to the conventional method, then disassemble, collect the battery cells, and set them aside;

[0054] (2) Pulverize the battery cells, discharge the diaphragm scraps of the pulverized material through winnowing, and then sieve (screen 150 mesh) the remaining pulverized material to obtain a mixture containing copper foil and aluminum foil and black powder; The mixture with aluminum foil is sent to the gravity separator for gravity separation to obtain copper foil and aluminum foil respectively.

[0055] (3) Take the black powder and place it in the first stirred tank, then add hydrochloric acid solution (5mol / L), the dosage ratio of the black powder and hydrochloric acid solution is 1kg: 20L, heat up to 70°C and stir for 2h, and the reaction The resulting material is discharged, filtered, and the filter residue and filtrate are collected resp...

Embodiment 2

[0066] (1) Take the waste nickel-cobalt lithium manganese oxide battery and the waste lithium iron phosphate battery and discharge them according to the conventional method, then disassemble them, first remove the shell, take out the batteries, collect the batteries, and set them aside;

[0067] (2) Pulverize the battery cells, discharge the diaphragm scraps of the pulverized material through winnowing, and then sieve (screen 250 mesh) the remaining pulverized material to obtain a mixture containing copper foil and aluminum foil and black powder; The mixture with aluminum foil is sent to the gravity separator for gravity separation to obtain copper foil and aluminum foil respectively;

[0068] (3) Get the black powder and place it in the first stirred tank, then add sulfuric acid solution (3mol / L) and hydrogen peroxide (hydrogen peroxide content is 30w / w%), the consumption ratio of the black powder, sulfuric acid solution and hydrogen peroxide 1kg: 10L: 30L, heat up to 50°C an...

Embodiment 3

[0079] Repeat Example 1, the difference is:

[0080] Step (1) is performed as follows:

[0081] (1.1) Take the waste nickel-cobalt lithium manganese oxide battery and the waste lithium iron phosphate battery and mix them together, put them into the airtight discharge battery, pour water into the discharge battery, make the battery completely submerged in water, soak the battery in water for 5 days, collect The gas released during the battery soaking (discharging) process is sent to the condenser for condensation; after soaking, the solid and liquid are collected separately to obtain the discharged battery and the solution containing the electrolyte;

[0082] (1.2) Place the discharged battery in an electric dryer, dry it at 100°C for 4 hours, collect the gas generated during the drying process, and send it to a condenser for condensation; after drying, obtain a dried battery;

[0083] (1.3) Send the dried battery into the glove box for disassembly, remove the shell of the bat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com