Mixing disinfectant containing chlorine dioxide and preparing process thereof

A technology of chlorine dioxide and disinfectant, applied in the direction of disinfectant, botany equipment and method, biocide, etc., can solve the problems of strong corrosion, unfavorable application of disinfectant, poor stability, etc., and achieve the effect of improving the use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

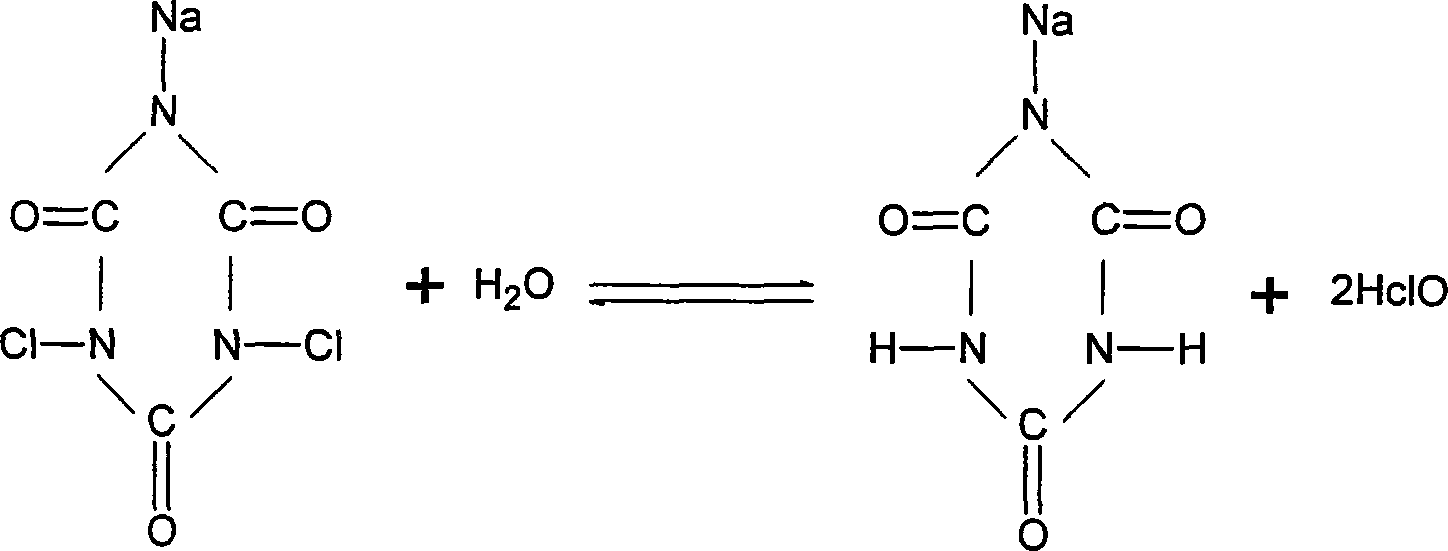

Image

Examples

Embodiment 1

[0038] Embodiment 1: after adding 1 liter of water in the container, add 20 gram sodium chlorites, add the trichloroisocyanuric acid of 16 grams again, stir, trichloroisocyanuric acid is dissolved, generate yellow-green chlorine dioxide, dichloroisocyanuric acid Sodium chloroisocyanurate mixed solution.

Embodiment 2

[0039] Embodiment 2: After adding 1 liter of water in the container, add 1 gram of potassium chlorite, then add 1.5 grams of trichloroisocyanuric acid, stir, trichloroisocyanuric acid is dissolved, and generate yellow-green chlorine dioxide, dichloroisocyanuric acid Potassium cyanurate mixed solution.

Embodiment 3

[0040] Embodiment 3: after adding 1 liter of water in the container, add 100 gram lithium chlorites, then add 50 grams of trichloroisocyanuric acid, stir, trichloroisocyanuric acid is dissolved, generate yellow-green chlorine dioxide, dichloroisocyanuric acid Lithium chloroisocyanurate mixed solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com