Flue-gas desulfurizing engineering high-temperature flue-gas controlling system and controlling method thereof

A technology of temperature control system and high-temperature flue gas, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve the problems of threatening the safety of the chimney and damaging the anti-corrosion layer on the inner wall of the chimney, so as to achieve reliable system operation and reduce operation and maintenance. Cost, Effect of Feasible Setup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

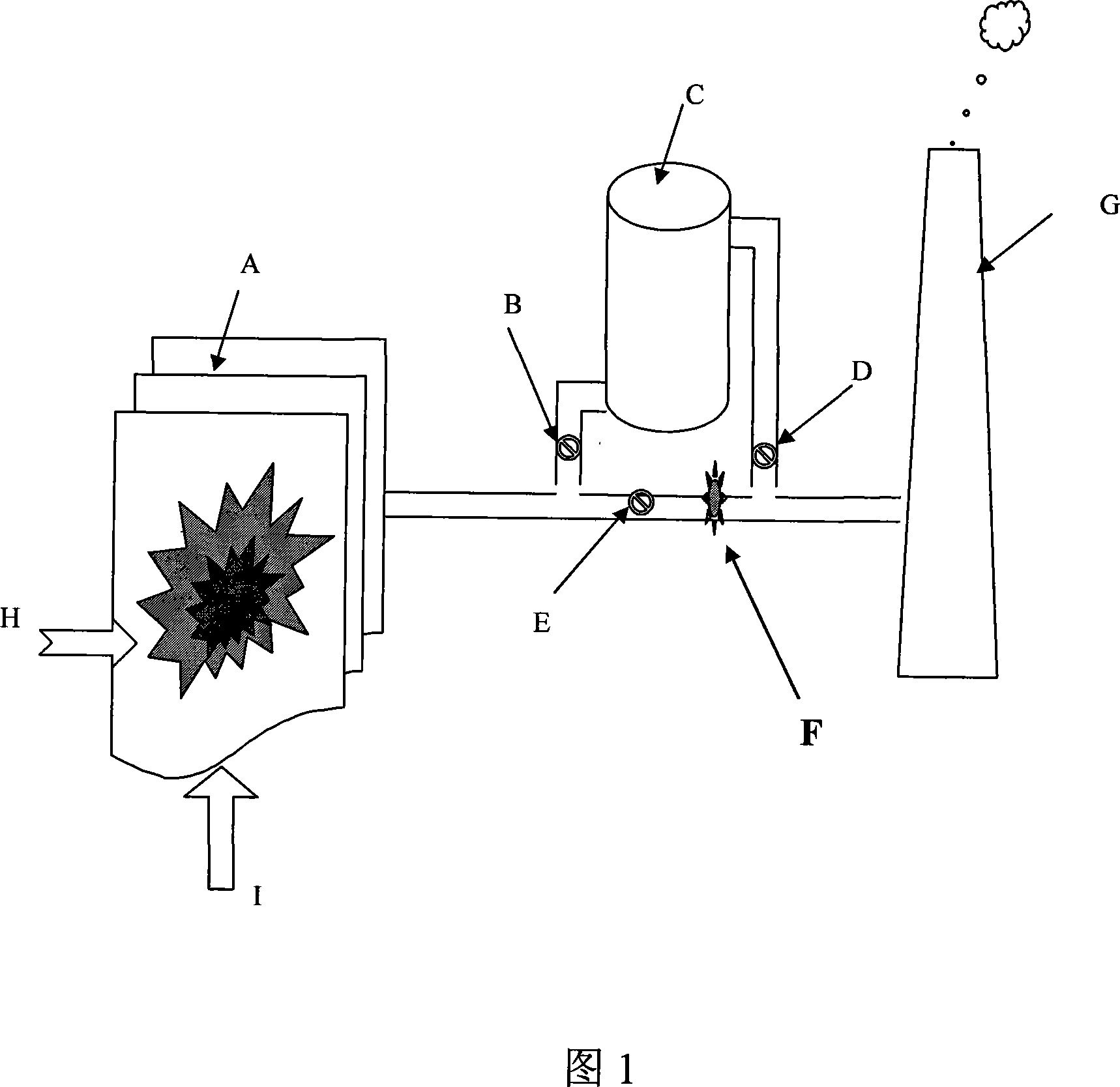

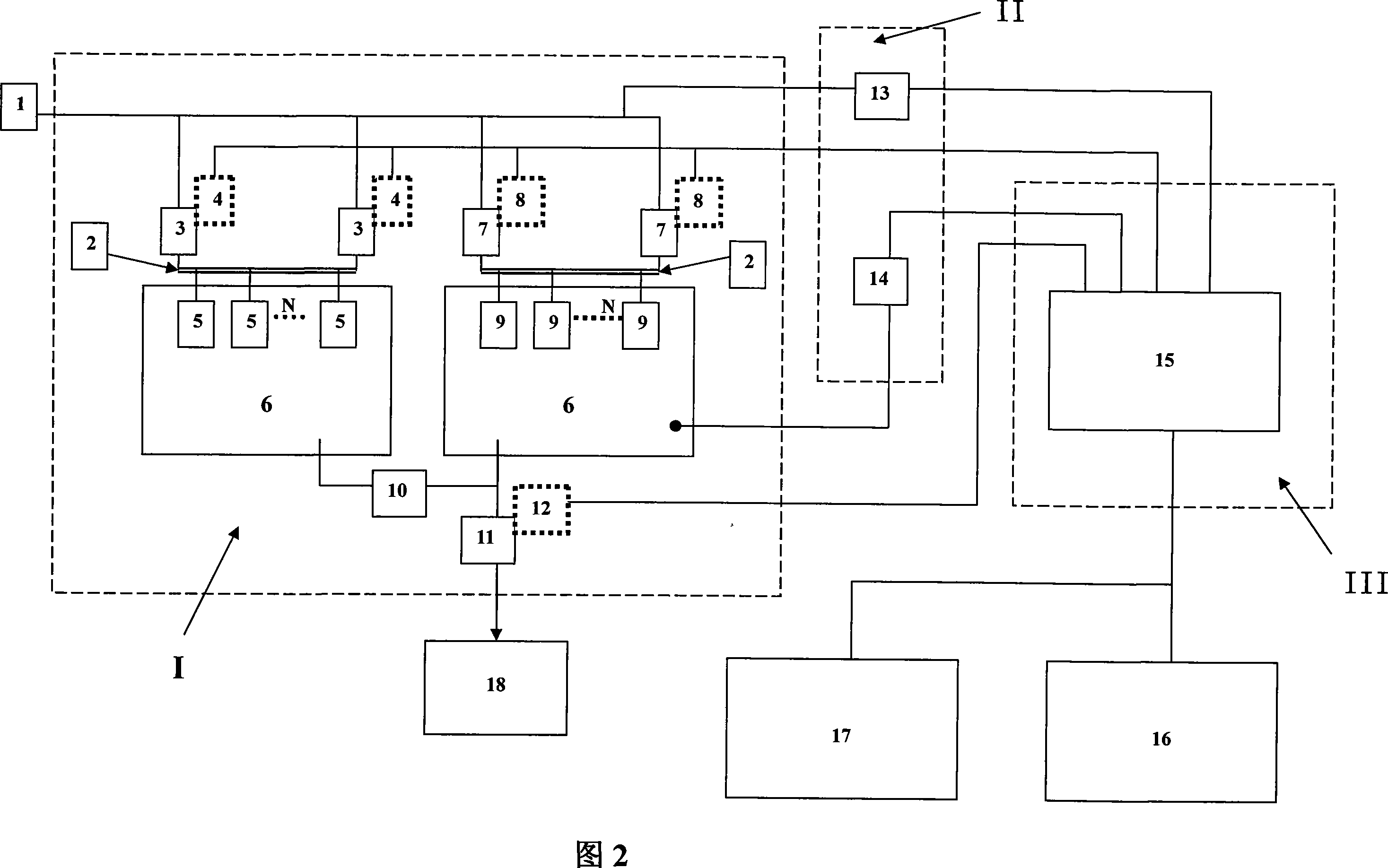

[0060] A high-temperature flue gas temperature control system for a flue gas desulfurization project based on the "basic technical scheme" and a method for controlling the temperature of high-temperature flue gas.

[0061] As shown in Figure 2: the high-temperature flue gas temperature control system of the flue gas desulfurization project includes a water spray device I, a flue gas temperature and spray water pressure monitoring device II and a control device III;

[0062] The water spray device I installed in the flue behind the bypass baffle of the desulfurization island is composed of an external water source / water supply pipe 1, a ring water supply pipe 2 for the water spray device, 2 electric control valves 3 for the spray layer and electric regulation for the spray layer Valve actuator 4, 8 spray layer mist water nozzles 5; 2 spare spray layer electric regulating valves 7 and their actuators 8, 8 spare spray layer mist water nozzles 9, outlet pipe 10, outlet pipe Compos...

Embodiment 2

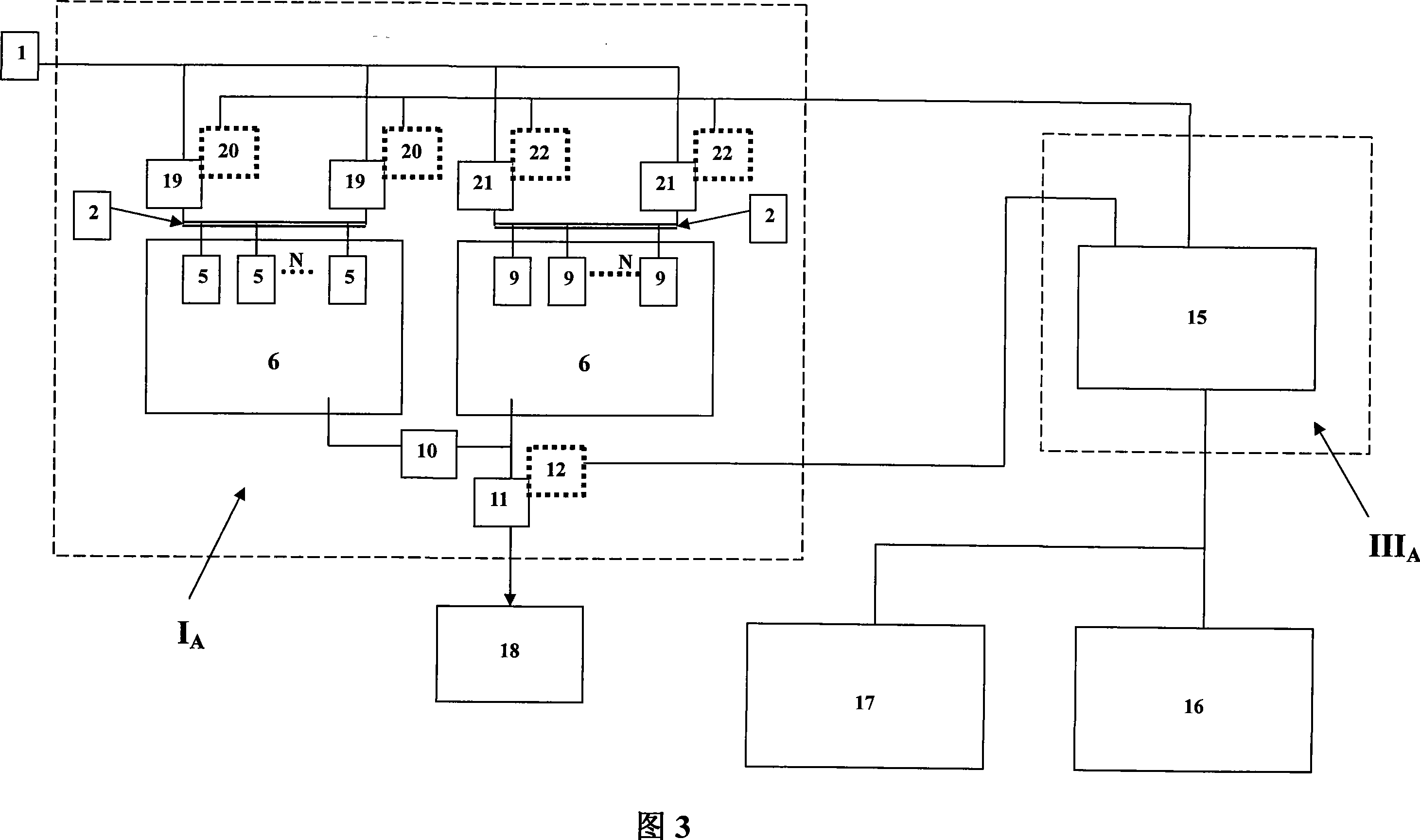

[0103] A high-temperature flue gas desulfurization project based on the "simplified technical solution" A temperature control system and a method for controlling the temperature of high-temperature flue gas.

[0104] The "simplified technical solution" of the second embodiment is different from the "basic technical solution" of the first embodiment in that: the "simplified technical solution" does not have a temperature sensor and a pressure sensor; the electric control valve is changed to an electric valve.

[0105] As shown in Figure 3: the high-temperature flue gas temperature control system of the flue gas desulfurization project of this "simplified technical solution" includes water spraying device I A and control gear III A .

[0106] The water spray device I A The setting principle is the same as that of the water spray device in the "basic technical plan", but the spray layer electric regulating valve and its actuator of the "basic technical plan" use the spray lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com