Silo slipform construction technique

A construction technique and sliding technology, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problems of inability to adapt to the development of sliding form construction technology, the bulky form of the inner operation platform, assembly and disassembly Difficulties and other problems, to achieve the effect of easy control of verticality and torsion, simple construction technology and process, and convenient assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

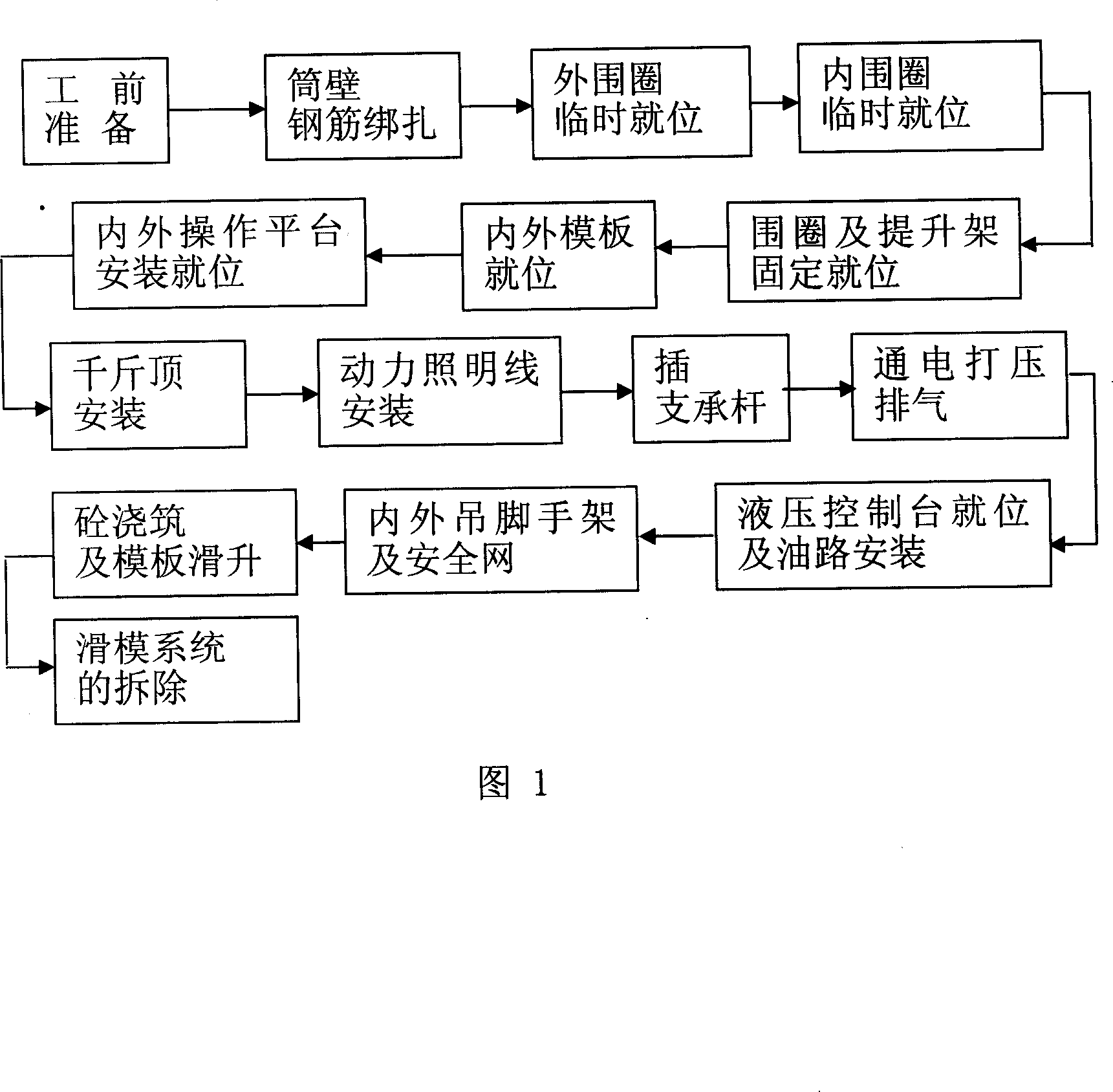

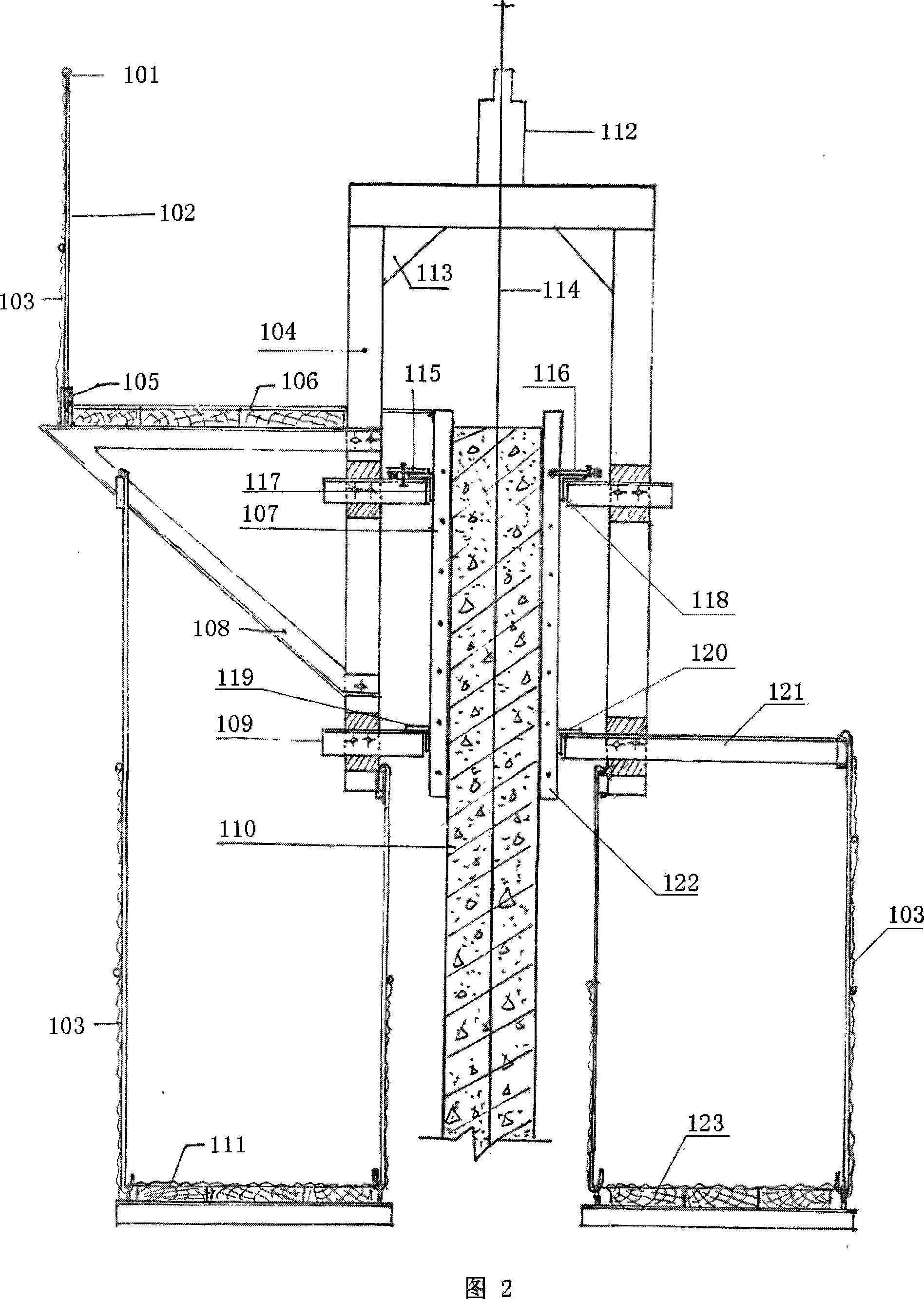

[0017] As shown in Figure 1, construction preparations need to be carried out before adopting the technique of the present invention, and the shallow circular silo slipform construction with a diameter of 30 meters is an example to illustrate the process of the present invention:

[0018] 1. Template design

[0019] 1.1. Use 1200mm×1200mm stereotyped combined steel formwork. The templates are connected with "U" type clips. The assembled formwork is tightened with "L" type tensioning screw and the circle. The upper and lower tensioning screws should be staggered from each other to Ensure that the formwork is evenly stressed. The single-side taper of the inner and outer formwork is 0.4%.

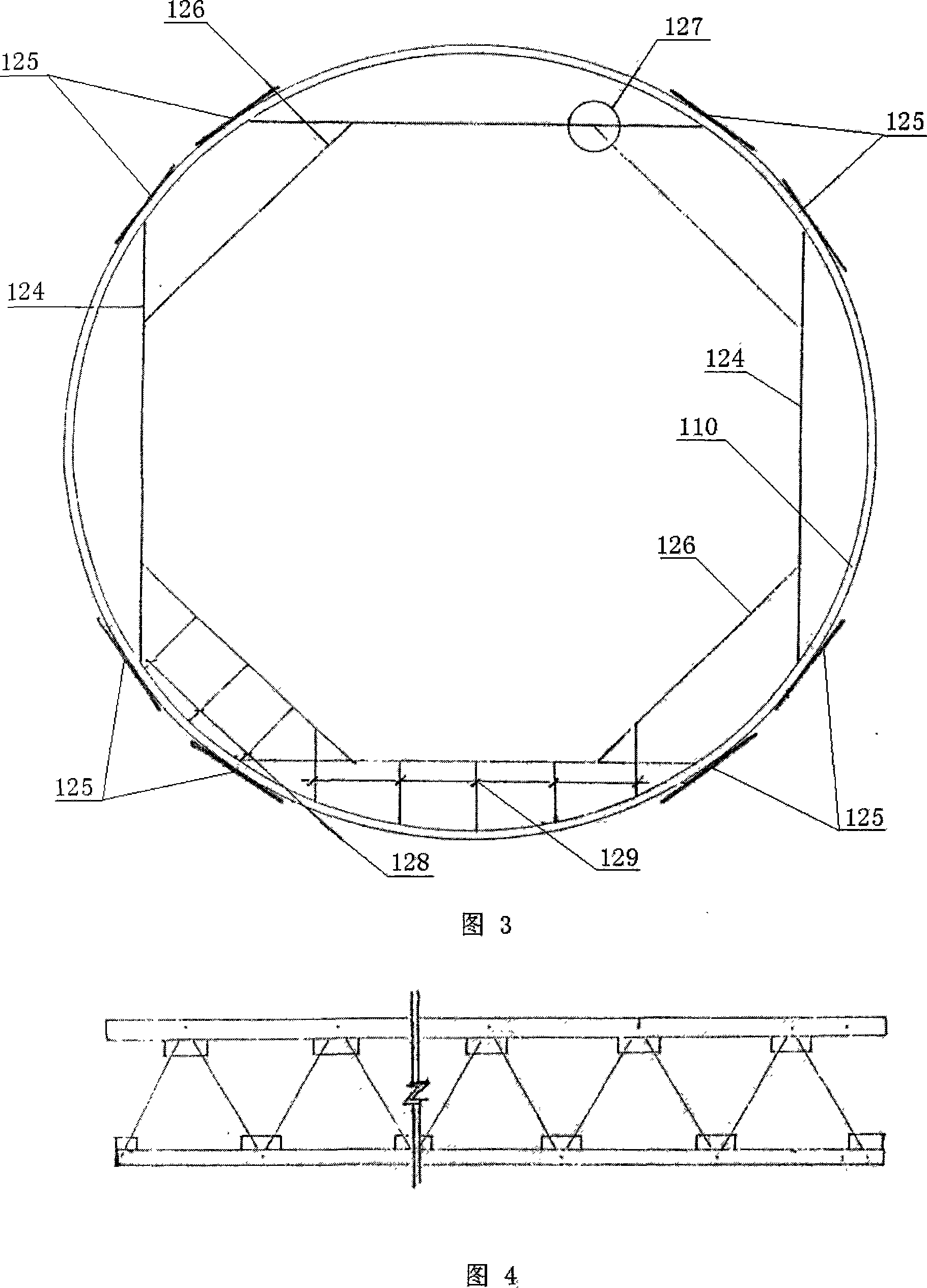

[0020] 1.2. The encirclement is checked and calculated strictly according to the design requirements. It is made by mechanical bending of ∠75×8 angle steel and manual correction. The arc should be natural and uniform, and the radius of the arc should match the design radius. R 上 内 =14943mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com