Water chilling unit applying natural cooling technology

A technology that applies nature and chillers. It is applied in applications, household heating, and household heating. It can solve the problems of increased power consumption of water pumps, high cost, and low efficiency of the unit, and achieve comprehensive efficiency and comprehensive cost. Simple installation , the effect of high operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific implementation will be described in detail below in conjunction with the accompanying drawings.

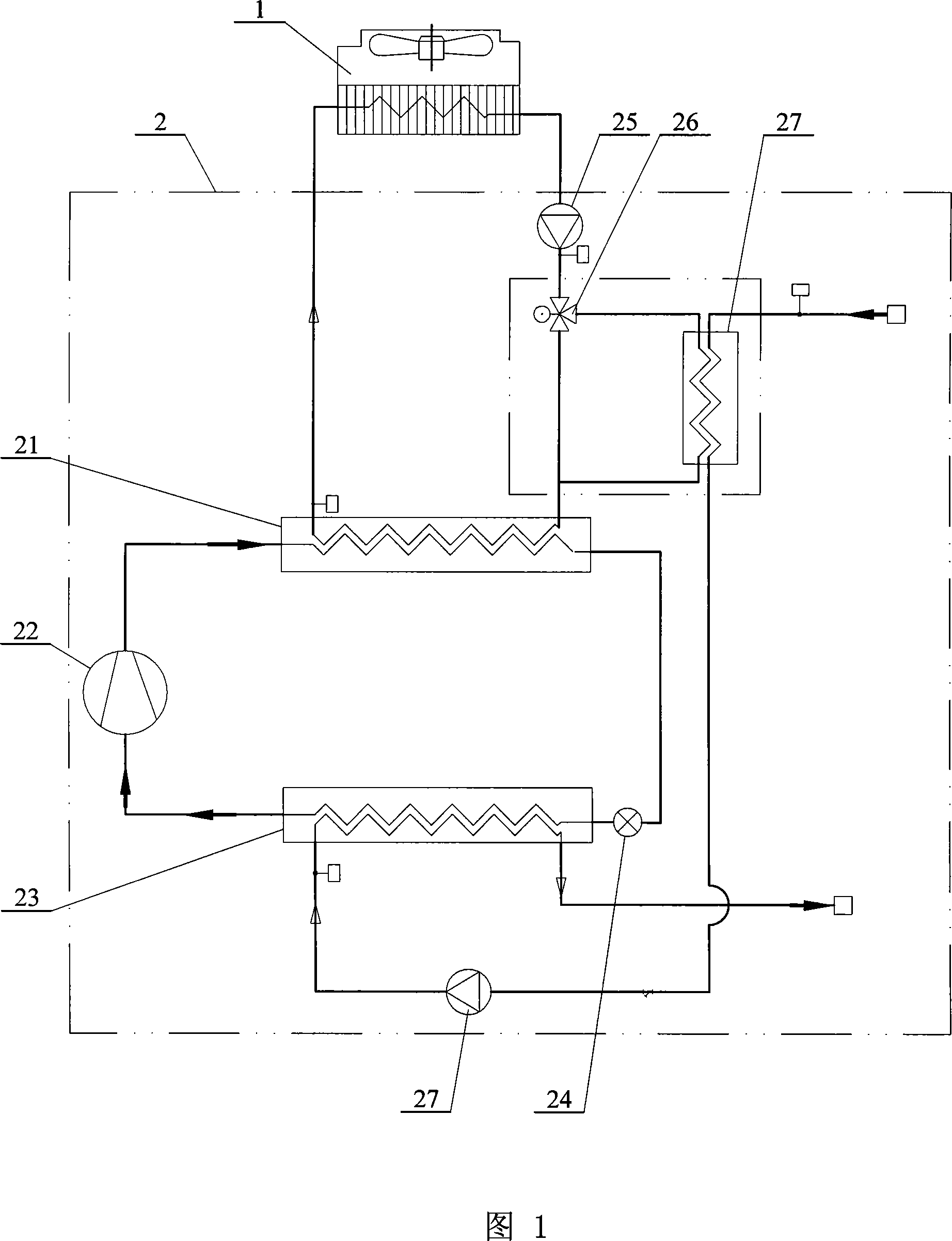

[0012] As shown in Figure 1, this embodiment is a chiller for process cooling, which requires 24-hour uninterrupted operation of the chiller; the outlet water temperature is maintained at 20°C all year round; the rated cooling capacity is 10kW; the cooling load demand is 5 to 9kW; The minimum outdoor temperature is -15°C; the maximum is 37°C. It consists of an indoor unit 2 and an outdoor unit 1; the indoor unit 2 includes a condenser 21, a compressor 22, an evaporator 23, an expansion valve 24 and a cooling pump 25, wherein the condenser 21, compressor 22, evaporator 23 and expansion The valve 24 forms a sealed system through the pipeline, the outdoor unit 1 and the condenser 21 form a cooling water circulation through the pipeline, and the cooling pump 25 is arranged on the return water pipeline of the cooling water circulation, and it also includes a three-w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com