High precision broad frequency contaminated insulator leakage current sensor

A leakage current and wide-band technology, which is applied in the field of insulator AC leakage current detection sensors, can solve the problems of incompatibility between frequency band and sensitivity, large impact of on-site interference, and poor application effect, so as to improve anti-interference ability, ensure response sensitivity, suppress Effects of Electromagnetic Interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

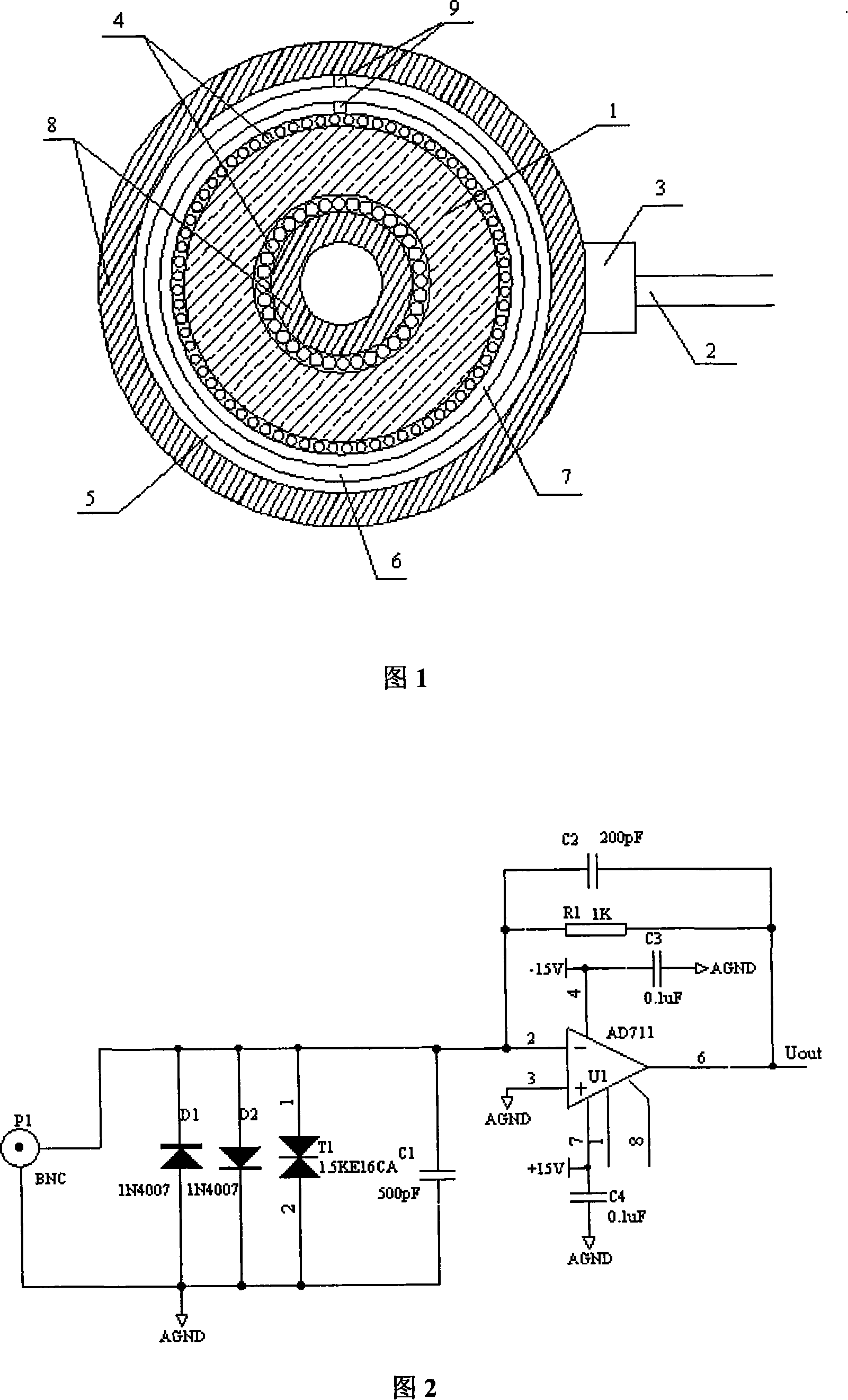

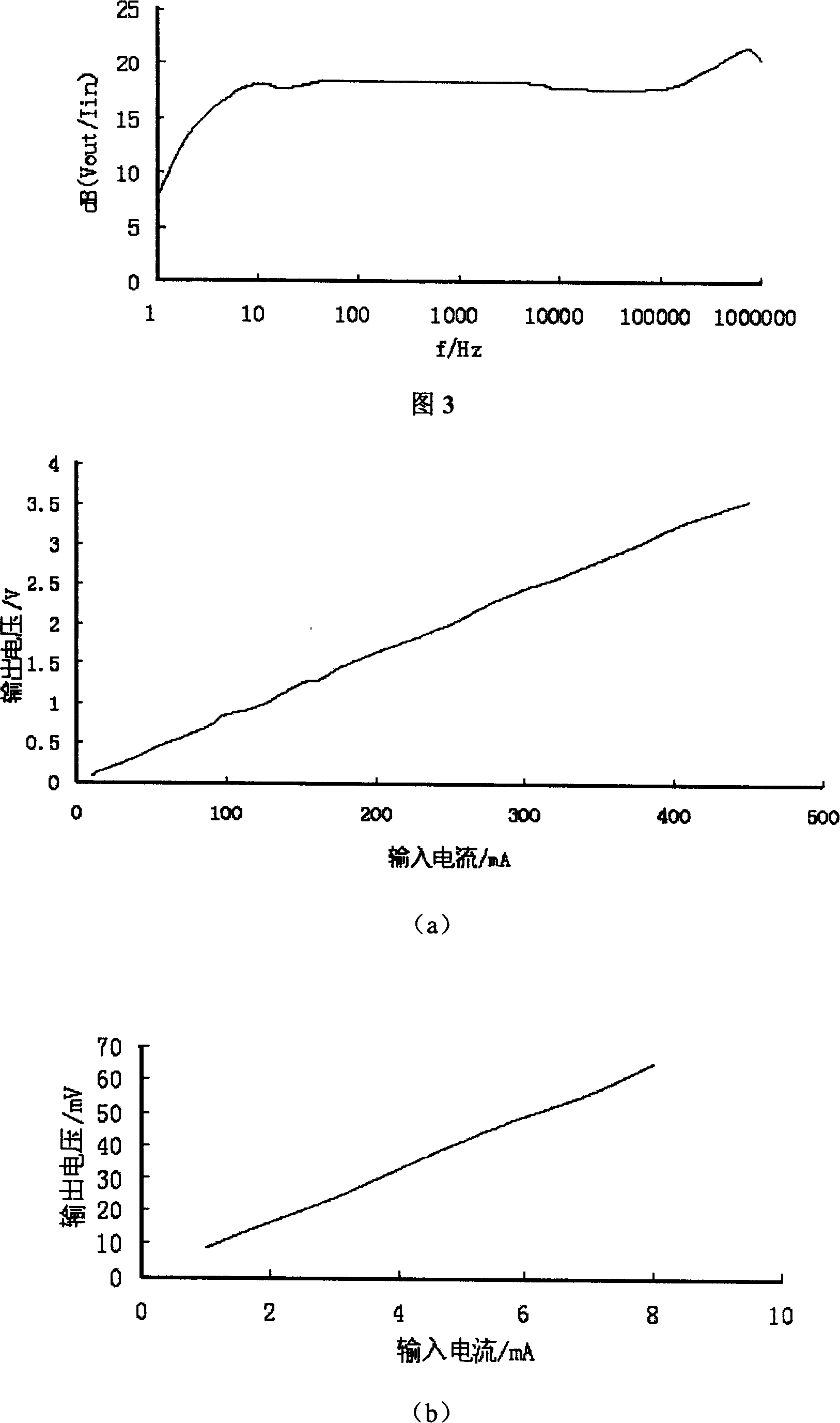

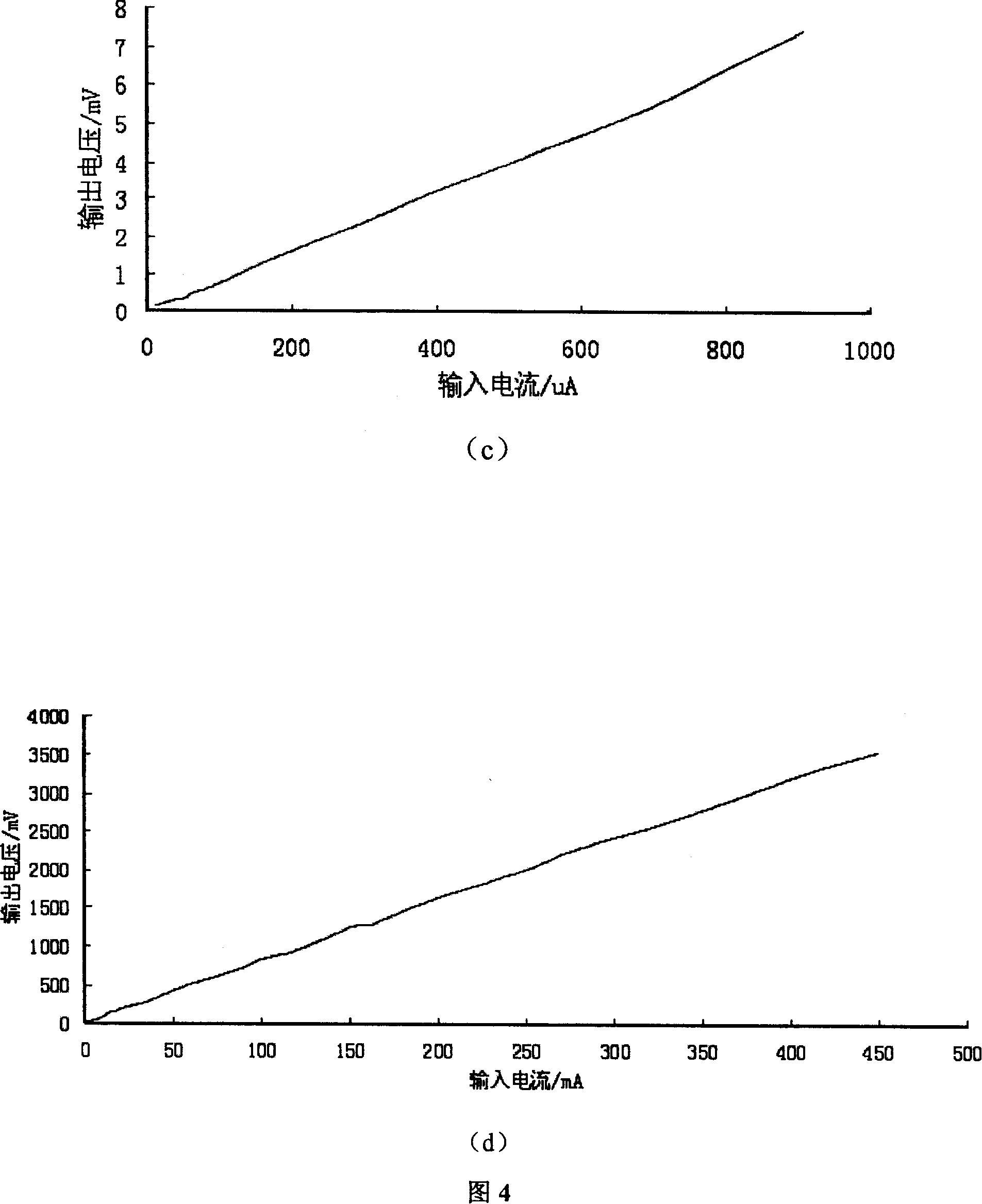

[0034] As shown in Figures 1 and 2, a high-precision broadband dirty insulator leakage current sensor mainly includes two parts, the Rogowski coil and the integral amplifier unit, which are connected by a coaxial cable 2 . The Rogowski coil is composed of a nanocrystalline alloy annular iron core 1 , a winding 4 , a double-layer shielding structure, an engineering plastic shell 8 and a coaxial cable connector 3 . Inside the housing 8, a winding 4 with 120 turns of enameled wire with a diameter of 0.19 mm, a nanocrystalline alloy annular iron core 1 and a double-layer shielding structure are respectively arranged from the inside to the outside, and the winding 4 is wound on the nanocrystalline alloy annular On the iron core 1, a double-layer shielding structure is arranged on the upper, lower and outer sides of the coil. The inner layer is a copper shielding layer 7, and the outer layer is an iron shielding layer 5, both of which have a thickness of 0.5 mm to shield external ele...

Embodiment 2

[0037] A high-precision broadband dirty insulator leakage current sensor mainly includes two parts, a Rogowski coil and an integral amplifier unit, which are connected by a coaxial cable 2 . The Rogowski coil is composed of a nanocrystalline alloy annular iron core 1 , a winding 4 , a double-layer shielding structure, an engineering plastic shell 8 and a coaxial cable connector 3 . Inside the housing 8, a winding 4 with 120 turns of enameled wire with a diameter of 0.19 mm, a nanocrystalline alloy annular iron core 1 and a double-layer shielding structure are respectively arranged from the inside to the outside, and the winding 4 is wound on the nanocrystalline alloy annular On the iron core 1, a double-layer shielding structure is arranged on the upper, lower and outer sides of the coil. The inner layer is a copper shielding layer 7, and the outer layer is an iron shielding layer 5, both of which have a thickness of 0.3 mm to shield external electromagnetic field interference....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com