Sound field particle vibration velocity sensitive structure and making method

A sensitive structure and particle velocity technology, which is applied in microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve the problems that limit the wide application of particle velocity measurement sensors, acoustic signal distortion, and high loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

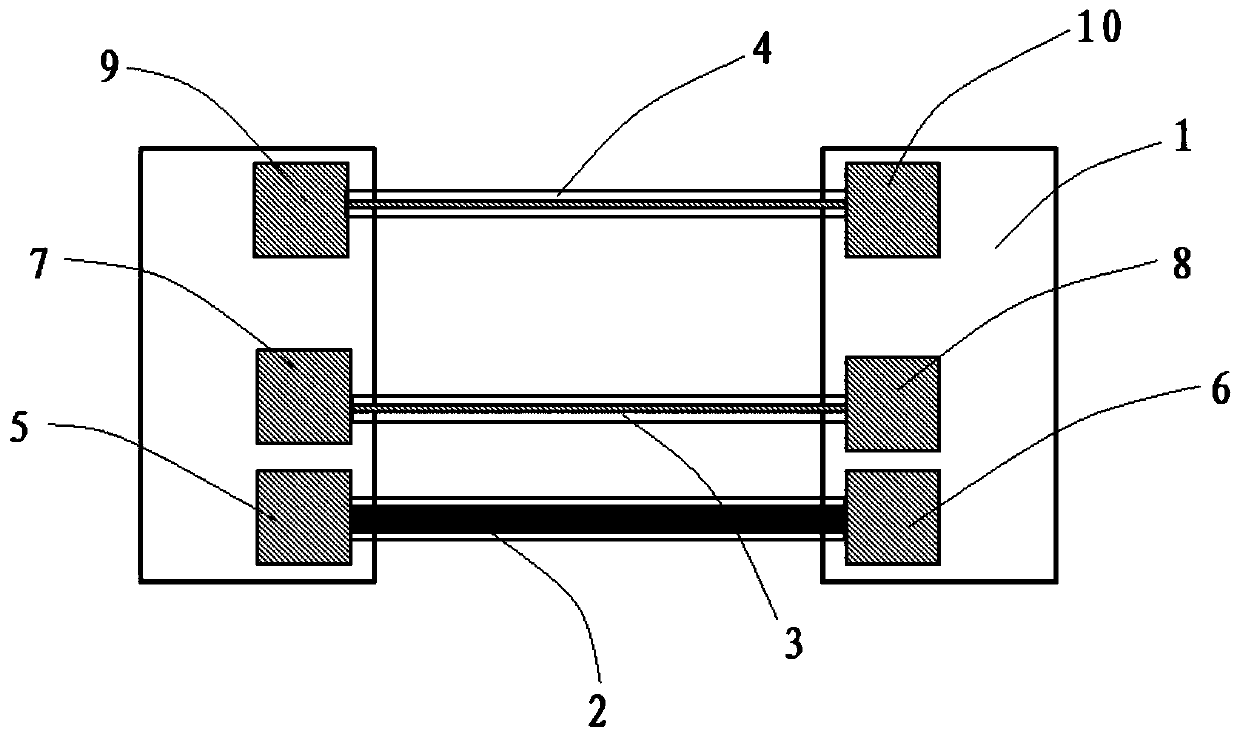

[0039] Such as figure 1 As shown, a bridge hole is formed on the silicon substrate 1, and a plurality of thin wires are provided. Corresponding to each thin wire, one electrode is respectively arranged on both sides of the bridge hole; among the plurality of thin wires, one thin wire is heated by electricity Thin wires, the other thin wires are sensitive thin wires, and the electric heating thin wires are located on the outermost side. Among the plurality of thin wires arranged from outside to inside, the distance between the thin wires gradually increases from outside to inside. In this embodiment, there are three thin wires, which are electrified heating thin wire 2, first sensitive thin wire 3, and second sensitive thin wire 4 from outside to inside, corresponding to each thin wire, and the two sides of the bridge hole are corresponding to each other. One electrode, that is, a first electrode 5 , a second electrode 6 , a third electrode 7 , a fourth electrode 8 , a fifth ...

Embodiment 2

[0042] In the second embodiment, the width of the electric heating thin wire 2 is 10 μm, the width of the sensitive thin wire is 2 μm, and the thickness of the thin wire is 0.4 μm. The distance between the first sensitive thin wire 3 and the electric heating thin wire 2 is 20 μm, and the distance between the first sensitive thin wire 3 and the second sensitive thin wire 4 is 80 μm. . All the other structures of embodiment two are the same as embodiment one.

[0043] The preparation method of the sound field particle velocity sensitive structure of the present invention comprises the following steps:

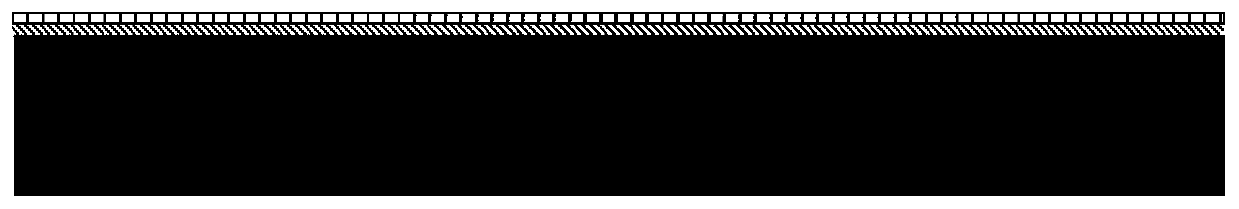

[0044] Step 1: If figure 2As shown, silicon oxide and silicon nitride support layers are sequentially deposited on a silicon substrate;

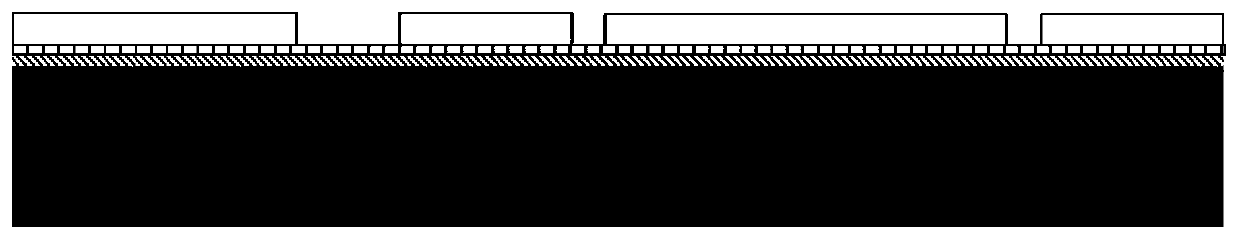

[0045] Step 2: If image 3 As shown, carry out glue coating, photolithography and development for the first time, and define the group of multiple micro-pitch thin wires, the first electrode, the second electrode, and the first acoustic fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com