Legalon mastication patch and method of preparing the same

A technology of silymarin and chewable tablets, which is applied in the field of silymarin chewable tablets and its preparation, can solve undiscovered problems and achieve the effects of low production cost, simple operation and improved dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

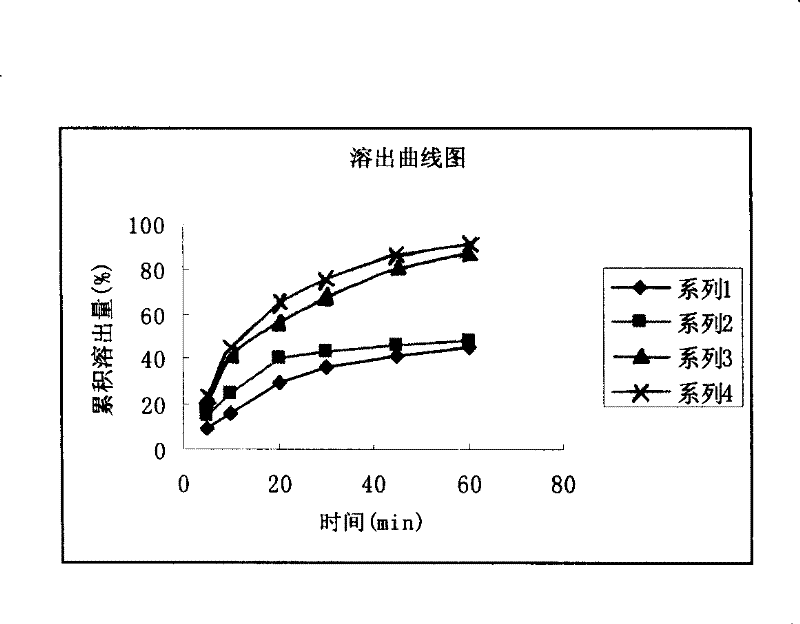

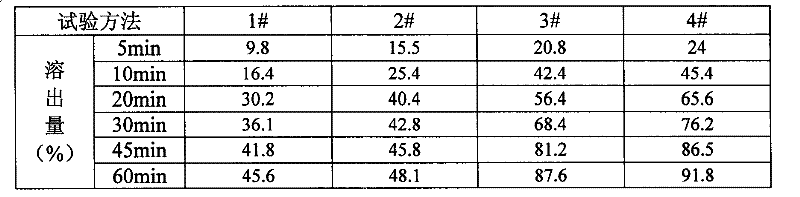

Image

Examples

Embodiment 1

[0034] Example 1: Take 200g of silymarin and dissolve it in 1500ml of 70°C absolute ethanol; take another 50g of mannitol and 40g of povidone K30, stir and dissolve it with 500ml of 55°C water, add it to the above alcohol solution after dissolution, stir evenly, and use it as silymarin Binder solution (60°C heat preservation). At the same time, take 150g of mannitol, 80g of starch, 10g of stevioside and 10g of pineapple essence to pass through a 80-mesh sieve and place them in a one-step granulator, boil evenly, and then spray the above-mentioned binding liquid at a constant speed for one-step granulation. Dry the water to less than 3.0%, take out the dry granules and use a 24-mesh sieve to granulate, add 2g of magnesium stearate, mix well, take samples to detect the content of intermediates, calculate the tablet weight (specification: 140mg / tablet), and press into tablets to obtain .

Embodiment 2

[0035] Example 2: Take 200g of silymarin and dissolve it in 1500ml of absolute ethanol at 70°C; take another 60g of sorbitol, 30g of povidone K30 and 10g of sodium bicarbonate, stir and dissolve it with 600ml of 55°C water, and add it to the alcohol solution after dissolving. Stir evenly, and use it as a silymarin binder solution (60°C heat preservation). At the same time, take 140g of sorbitol, 80g of starch, 15g of stevioside and 10g of pineapple essence to pass through a 80-mesh sieve and place them in a one-step granulator, boil evenly, and then spray the above-mentioned binding liquid at a constant speed for one-step granulation. Dry the water to less than 3.0%, take out the dry granules and use a 24-mesh sieve to granulate, add 2g of magnesium stearate, mix well, take samples to detect the content of intermediates, calculate the tablet weight (specification: 140mg / tablet), and press into tablets to obtain .

Embodiment 3

[0036]Example 3: Take 200g of silymarin and dissolve it in 1800ml of ethanol above 70°C; take another 50g of mannitol, 30g of povidone K30 and 10g of sodium bicarbonate, stir and dissolve it with 500ml of 55°C water, add it to the above alcohol solution after dissolving, and stir Evenly, as a silymarin binder solution (60°C heat preservation). At the same time, take 150g of mannitol, 80g of starch, 10g of aspartame, and 10g of orange essence to pass through a 80-mesh sieve and put them in a one-step granulator, boil evenly, then spray the above-mentioned binding liquid at a constant speed, and carry out one-step granulation. When the moisture content of the granules is less than 3.0%, take out the dry granules and sieve them with a 24-mesh sieve, add 1g of magnesium stearate and 1g of talc, mix well, take samples to detect the content of intermediates, and calculate the tablet weight (specification: 140mg / tablet) , pressed into tablets, ready to use.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap