Preparation method of ivermectin sustained-release microspheres

A technology of ivermectin and slow-release microspheres, which is applied to medical preparations with non-active ingredients, medical preparations containing active ingredients, and pharmaceutical formulas, etc., and can solve problems such as short half-life, poor stability, and hindering applications. Achieve the effect of easy absorption, good stability and reduced dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

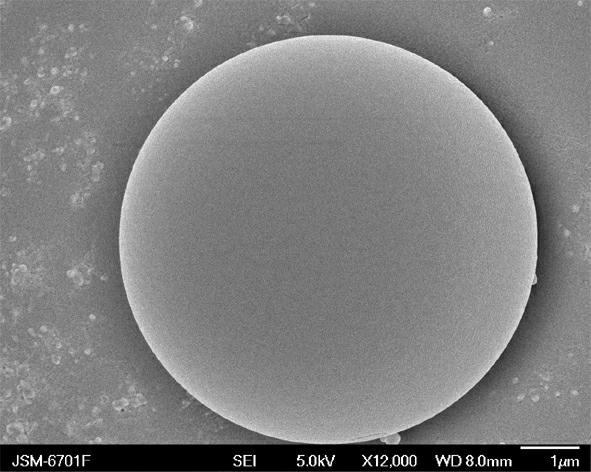

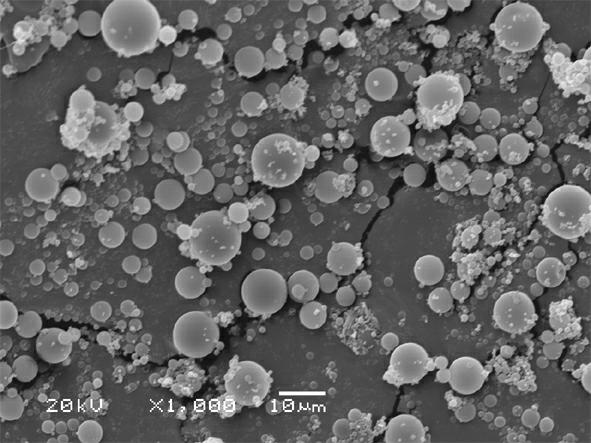

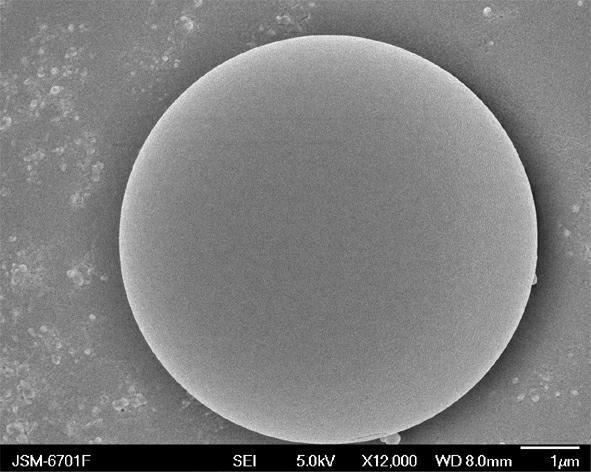

[0029] Example 1: Preparation of ivermectin polylactic acid sustained-release microspheres.

[0030] Accurately weigh 0.5g of polylactic acid and 0.25g of drug ivermectin and dissolve in 20ml of a mixed solution of dichloromethane and acetone, the volume percentage of dichloromethane and acetone is 9:1, and ultrasonically ultrasonicate for 5 minutes to fully dissolve to form an oil phase , the relative molecular mass of polylactic acid is 10,000; at a temperature of -10°C to 30°C, inject the oil phase dropwise into 40ml containing 2.0% (g / ml) polyvinyl alcohol and 0.1% (g / ml) Tween 80 Stir in the aqueous solution (water phase) at 2000rpm for 2min to form S / O / W 1 The first emulsion; then the resulting S / O / W 1 For the first time, inject the emulsion into 60ml aqueous solution containing 1.0% (g / ml) polyvinyl alcohol and 0.1% (g / ml) Tween 80, stir at 400rpm for 4h until the organic solvent evaporates completely, forming S / O / W 2 second emulsion; again S / O / W 2 The second emulsio...

Embodiment 2

[0032] Accurately weigh 0.5g of polylactic acid and 0.25g of drug ivermectin and dissolve in 20ml of a mixed solution of dichloromethane and acetone (the volume percentage of dichloromethane and acetone is 9:1), and ultrasonically sonicate for 5 minutes to fully dissolve to make oil phase, the relative molecular mass of polylactic acid is 25,000; at a temperature of -10°C to 30°C, inject the oil phase dropwise into 40ml containing 2.0% (g / ml) polyvinyl alcohol and 0.1% (g / ml) Tween Stir in 80 aqueous solution (water phase) at 2000rpm for 2min to form S / O / W 1 The first emulsion; then the resulting S / O / W 1 For the first time, inject the emulsion into 60ml aqueous solution containing 1.0% (g / ml) polyvinyl alcohol and 0.1% (g / ml) Tween 80, stir at 500rpm for 4h until the organic solvent evaporates completely, forming S / O / W 2 second emulsion; again S / O / W 2 The second emulsion was centrifuged at 4000rpm for 20min, washed twice with deionized water, the microspheres were collected,...

Embodiment 3

[0034] Accurately weigh 0.5g of polylactic acid and 0.35g of drug ivermectin and dissolve in 20ml of a mixed solution of dichloromethane and acetone (the volume percentage of dichloromethane and acetone is 8:2), and ultrasonically sonicate for 5 minutes to fully dissolve to make oil phase, the relative molecular mass of polylactic acid is 10,000; at a temperature of -10°C to 30°C, inject the oil phase dropwise into 20ml containing 2.0% (g / ml) polyvinyl alcohol and 0.1% (g / ml) Tween Stir in 80 aqueous solution (water phase) at 2000rpm for 2min to form S / O / W 1 The first emulsion; then the resulting S / O / W 1 For the first time, the emulsion was injected into 80ml of 1.0% (g / ml) polyvinyl alcohol and 0.1% (g / ml) Tween 80 aqueous solution, under the magnetic stirring of 500rpm for 4h until the organic solvent evaporated completely, forming S / O / W 2 second emulsion; again S / O / W 2 The second emulsion was centrifuged at 4000rpm for 20min, washed twice with deionized water, the microsp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com