Biological pesticide dust agent

A bio-pesticide and dust technology, applied in the field of pesticides, can solve the problems of increasing air humidity in facilities, unfavorable pests and diseases, and high labor intensity, and achieve the effects of increasing suspension time, saving pesticides, and good spraying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 4×10 8 Preparation of a spore / gram subtilis spore dust agent and determination of its control effect on potted cucumber botrytis:

[0048] Recipe 1 4×10 9 spores / gram subtilis spore powder: sodium lauryl sulfate: sodium lignosulfonate: sodium carboxymethylcellulose: diatomaceous earth: white carbon black = 10:1.5:5:2:66.5:15. Among them, 4×10 9 A spore / gram subtilis spore powder accounts for 10% of the total weight, the wetting agent sodium lauryl sulfate accounts for 1.5% of the total weight, the dispersant sodium lignosulfonate accounts for 5% of the total weight, and the protective agent carboxymethyl cellulose 2% of plain sodium, diatomaceous earth accounts for 66.5% of the total weight, and white carbon black accounts for 15% of the total weight. After mixing, jet mill crushing and secondary mixing, the fineness of the dust agent reaches D90=19.10μm, D50=8.13μm, D10=2.814μm

[0049] Recipe 2 4×10 9 spores / gram subtilis spore powder: sodium lauryl sulfate: sodi...

Embodiment 2

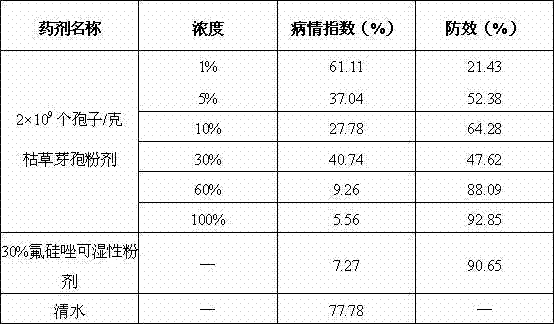

[0055] The configuration of different concentrations of Bacillus subtilis dust agent and its effect on the control of potted zucchini powdery mildew:

[0056] Blank powder configuration: sodium lauryl sulfate: sodium lignosulfonate: sodium carboxymethyl cellulose: diatomaceous earth: white carbon black = 1.5:5:2:76.5:15. Wherein, each dose of Bacillus subtilis powder accounts for 10% of the total weight, the wetting agent sodium lauryl sulfate accounts for 1.5% of the total weight, the dispersant sodium lignosulfonate accounts for 5% of the total weight, and the protective agent carboxymethyl fiber 2% of plain sodium, diatomaceous earth accounts for 66.5% of the total weight, and white carbon black accounts for 15% of the total weight. After mixing, jet mill pulverization and secondary mixing, the fineness of dust agent reaches D90=16.15μm, D50=9.32μm, D10=3.77μm.

[0057] Configuration of different concentrations of subtilis spore dust agent: combine 2×10 9 A spore / gram sub...

Embodiment 3

[0071] 2×10 8 spores / gram Gliocus dust agent preparation: 4×10 9 spores / gram Glycladium powder accounts for 5% of the total weight, the wetting agent saponin powder accounts for 1.5% of the total weight, the dispersant sodium lignosulfonate accounts for 5% of the total weight, and the protective agent sodium carboxymethylcellulose 2%, diatomite accounts for 71.5% of the total weight, and white carbon black accounts for 15% of the total weight. After mixing, jet mill pulverization and secondary mixing, the fineness of dust agent reaches D90=17.23μm, D50=15.22μm, D10=7.35μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com