Method for preparing clean fuel from wet garbage

A clean fuel and garbage technology, applied in fuel, solid fuel, biofuel, etc., can solve problems such as organic fertilizer food safety hazards, achieve good application prospects, high combustion efficiency, and solve the effects of food safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

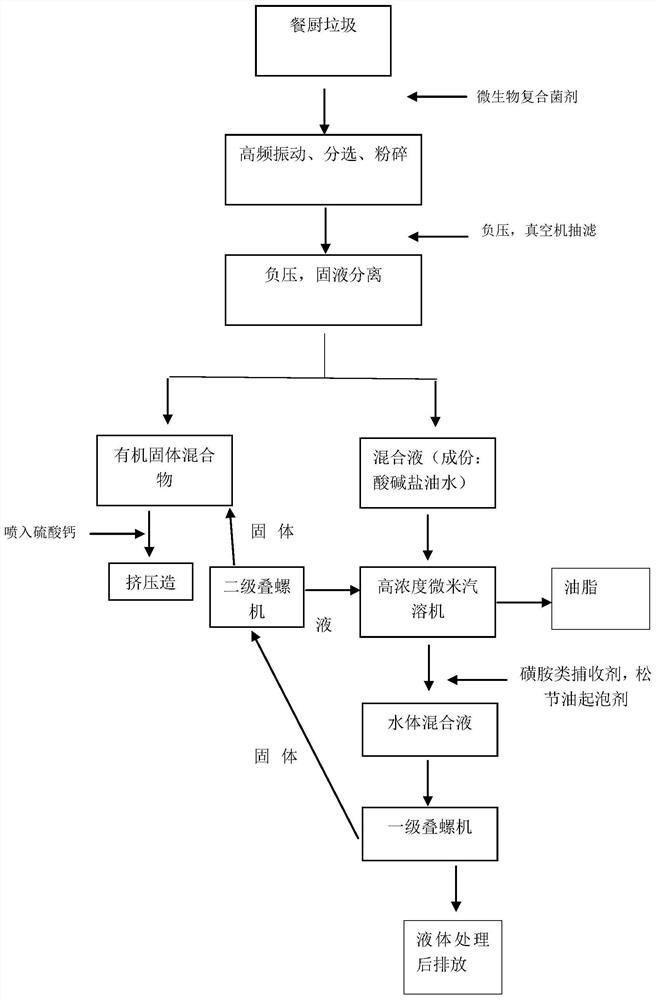

Image

Examples

Embodiment 1

[0025] (1) Spray 2% microbial composite bacteria agent to the collected wet garbage, and the processed product is vibrated, crushed and sorted;

[0026] (2) Grinding the dry matter after the above treatment to a particle size ≤ 1.3mm under negative pressure (-0.6Pa) conditions, and performing solid-liquid separation;

[0027] (3) The liquid mixture obtained after the solid-liquid separation in step (2) is sent into a micron air-dissolving machine, and the oil and water mixed liquid are separated; 3‰ sulfa collector and 0.5‰ turpentine are added in the water mixed liquid The foaming agent is sent to the first-stage screw stacker, and the separation degree of solids in the liquid is improved through the principle of aeration and oxidation, and the first-grade solid product and the first-grade liquid product are separated; the first-grade liquid product is discharged after treatment, and the first-grade solid product is discharged. The product is separated by a secondary screw st...

Embodiment 2

[0029] (1) Spray 1% microbial composite bacterial agent to the collected wet garbage, and the processed product is vibrated, crushed and sorted;

[0030] (2) Grinding the dry matter after the above treatment to a particle size ≤ 1.3mm under negative pressure (-0.6Pa) conditions, and performing solid-liquid separation;

[0031] (3) The liquid mixture obtained after the solid-liquid separation in step (2) is sent into a micron air-dissolving machine to separate oil and water mixed liquid; add 1‰ sulfa collector and 0.5‰ turpentine to the water mixed liquid The foaming agent is sent to the first-stage screw stacker, and the separation degree of solids in the liquid is improved through the principle of aeration and oxidation, and the first-grade solid product and the first-grade liquid product are separated; the first-grade liquid product is discharged after treatment, and the first-grade solid product is discharged. The product is separated by a secondary screw stacker to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com