Automatic garbage processing system of passenger compartment of high speed passenger train

An automatic processing and passenger technology, applied in the direction of railway car body parts, sanitary equipment, transportation and packaging, etc., can solve the problems of labor-intensive, labor-intensive cleaning and tidying up, etc., to improve the sanitation environment, reduce labor intensity, improve The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

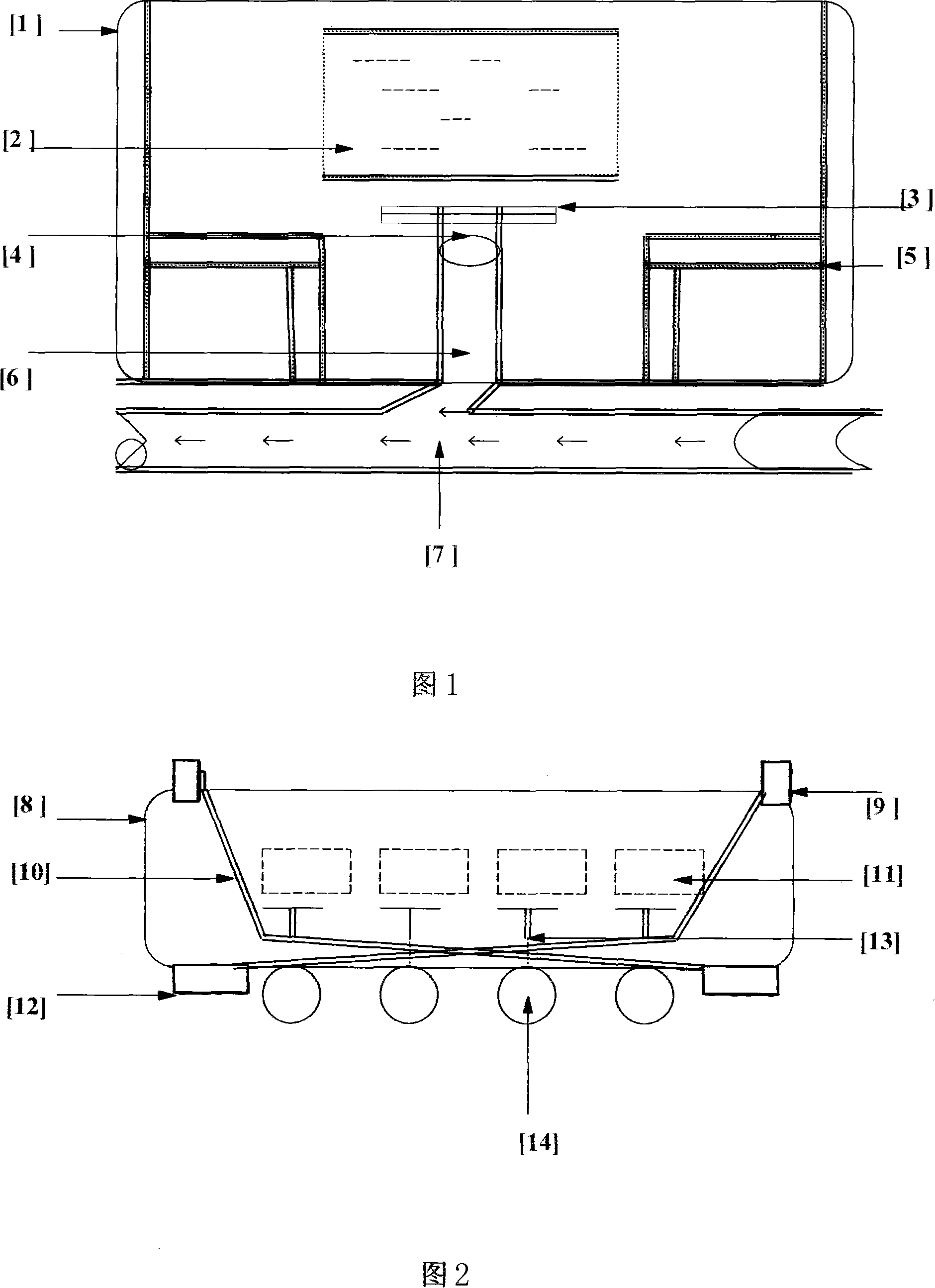

[0016] specific implementation plan

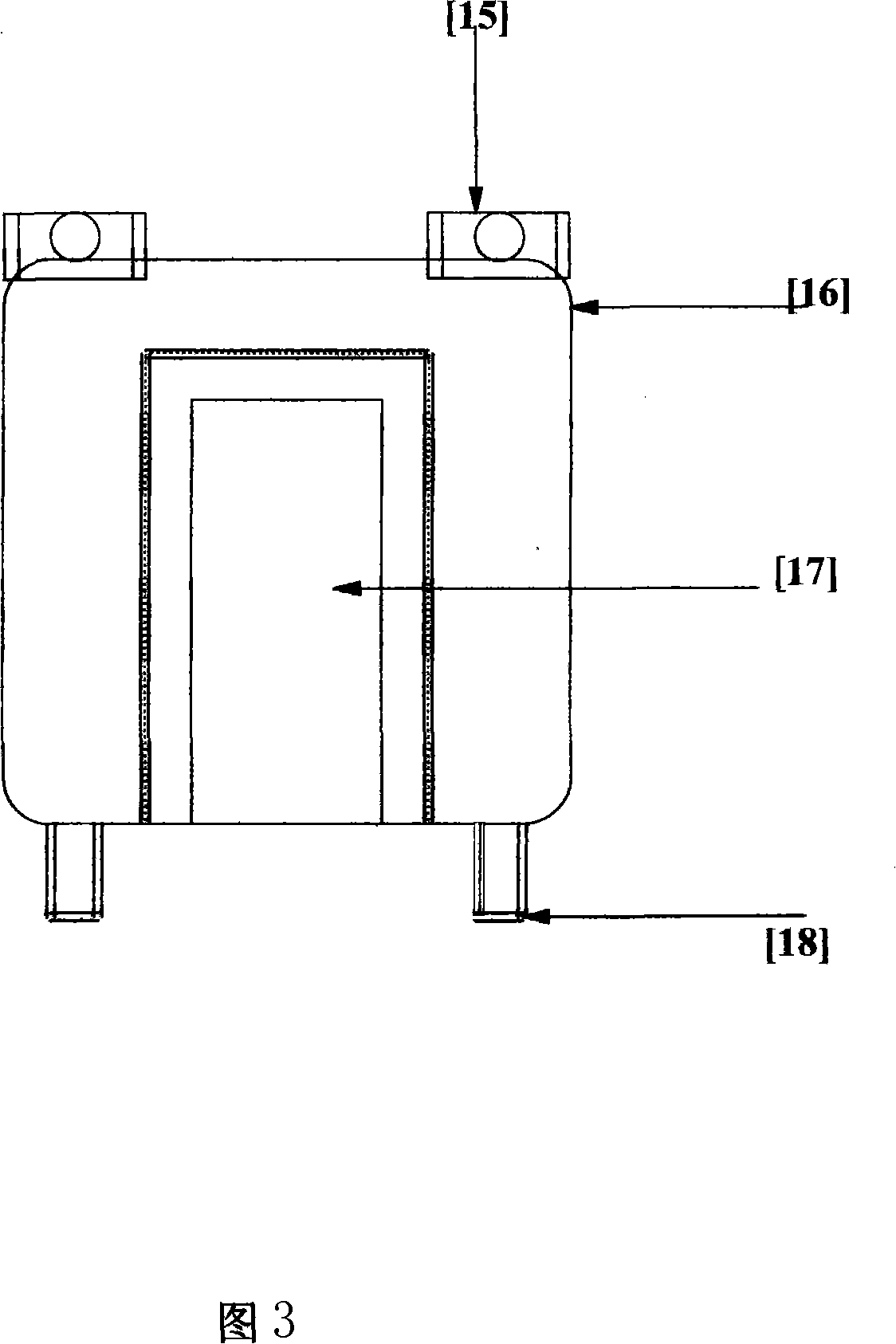

[0017] In the figure, the air-inducing bucket inlet [15] with adjustable flow rate installed on the top of each passenger car [8] traveling at high speed will introduce the flowing air with a certain potential energy opposite to the train running. In the work tube [7], there are multiple windows [2], [11] before each window [2], both sides of the passenger compartment [8] are provided with a table in front of the window [3]. The garbage delivery pipe [6] under each table is connected with the working pipe [7] laid under the floor on both sides of the carriage, and it is most convenient for passengers to drop in the vertical garbage delivery pipe [6]. Open the garbage drop-in port [4] on the appropriate position of the container, and the garbage drop-in port [4] should be manufactured and installed with double doors to ensure good sealing. When the flowing gas with potential energy in the working tube [7] passes through a garbage delivery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com