Flyerless spinning method and device with a drawing unit

A spinning machine and drafting technology, which is applied in the field of devices with a drafting mechanism, can solve problems such as difficult operability and inability to achieve tension drafting of cans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

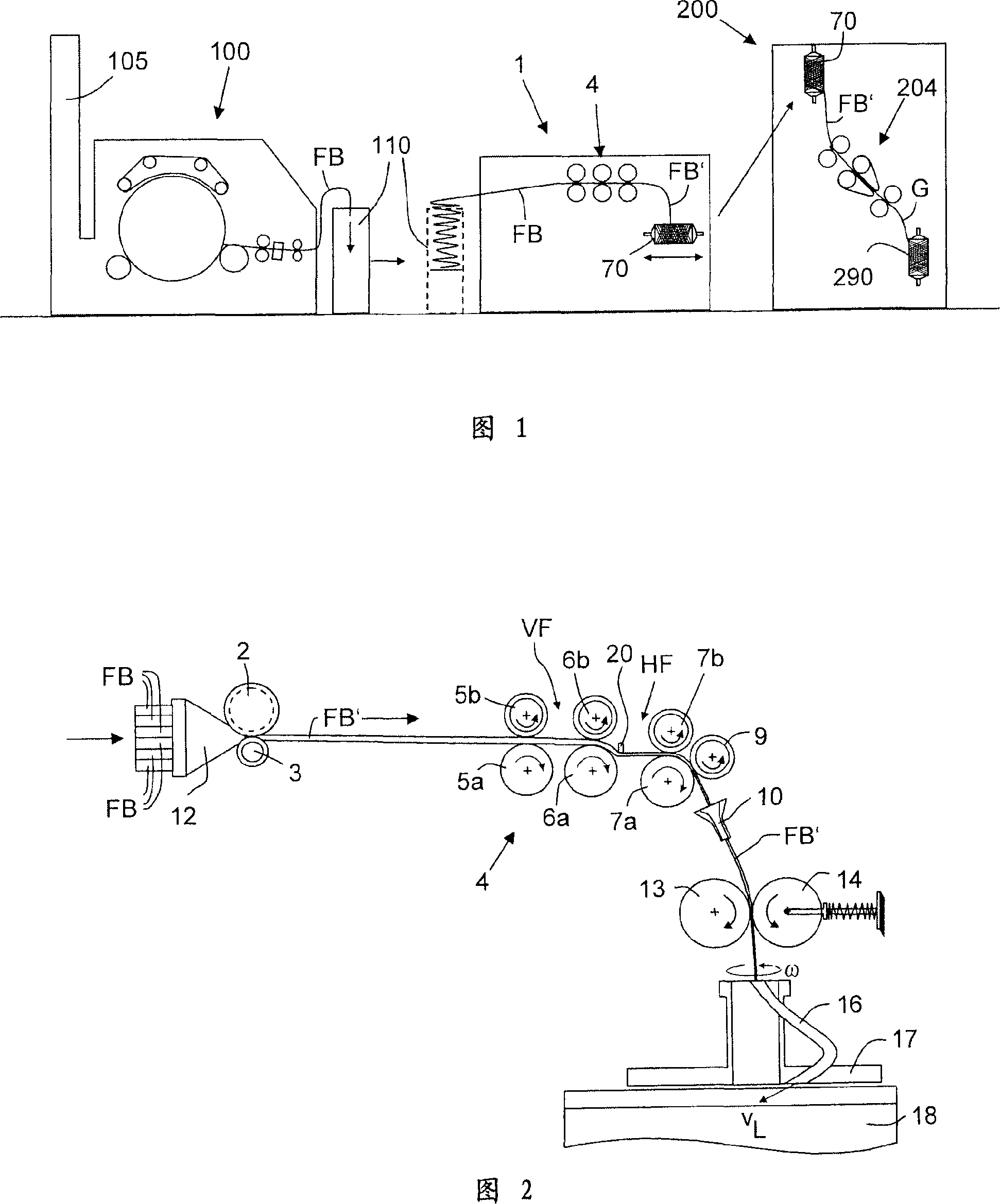

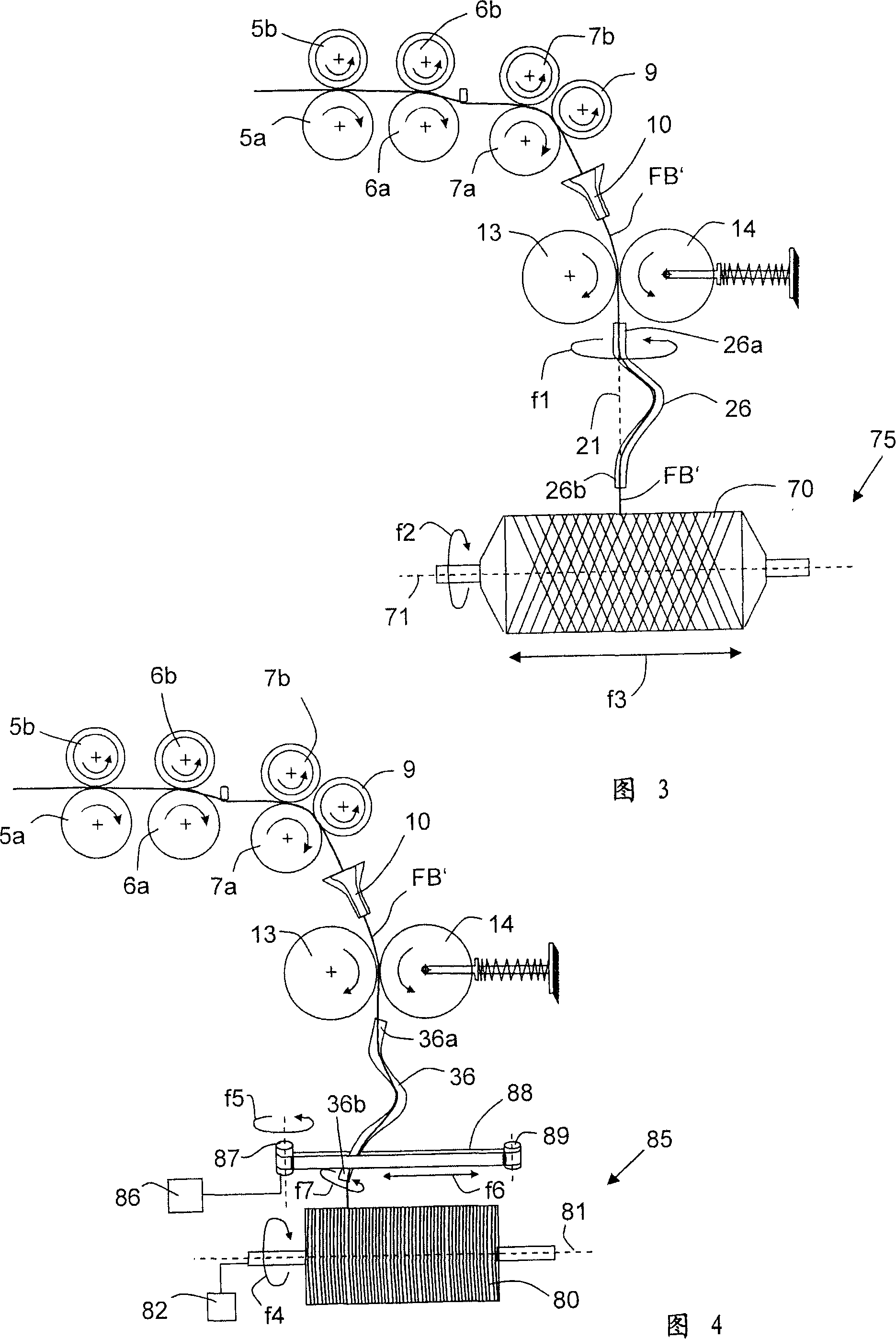

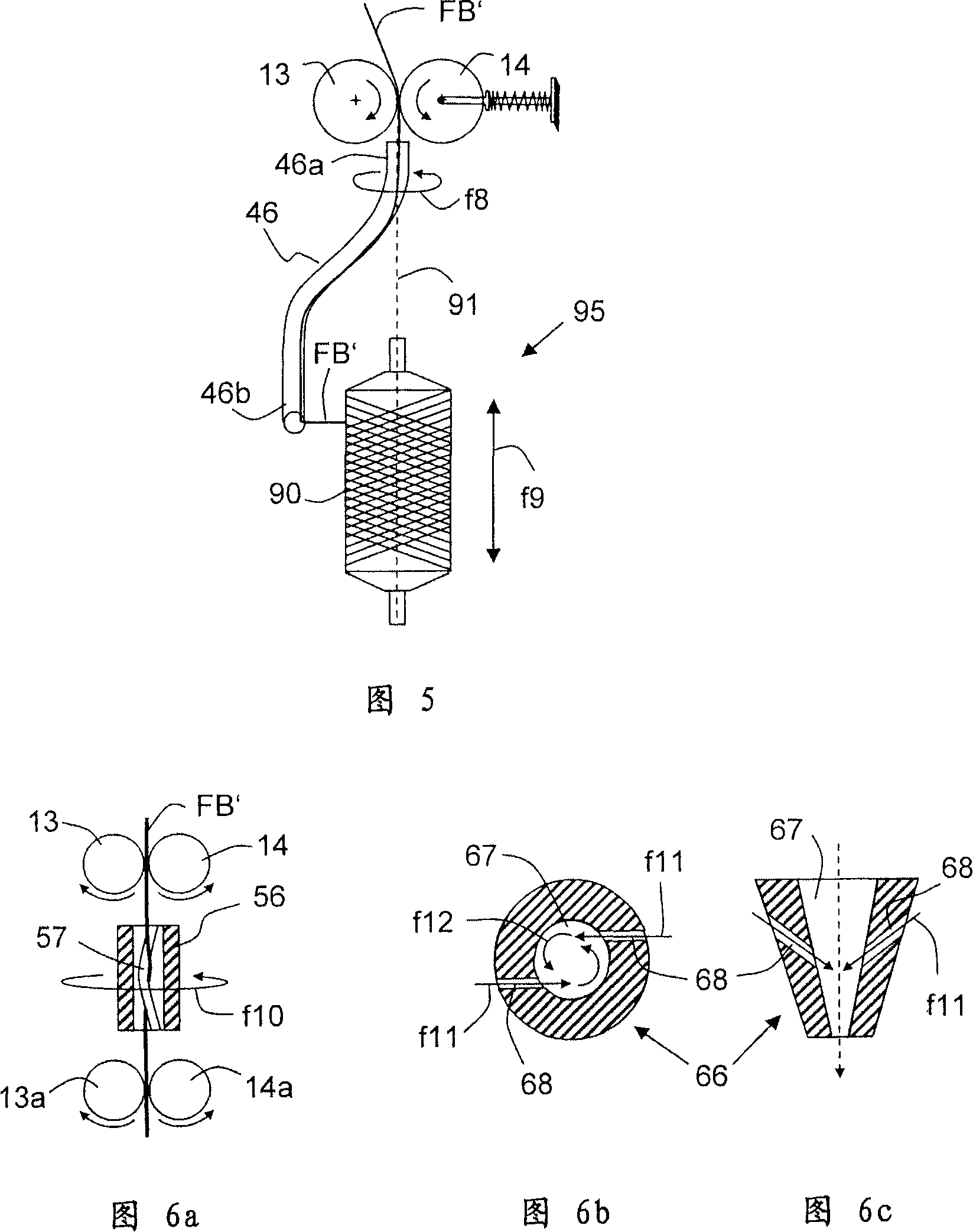

[0030] Figure 1 schematically shows the flow of a spinning machine. The vertical feed box 105 of the card 100 is supplied with cotton, for example, and the card 100 produces a fiber sliver FB from the cotton material by carding the cotton in a known manner. The fiber sliver FB can be deposited in a can 110 and then supplied to a downstream drafting device 1 (as shown in FIG. 1 ), or the fiber sliver FB' can be fed directly to the drafting device 1 . The drafting device 1 produces a fiber strand FB' from one or more fiber strands FB (only one fiber strand is shown), which is wound on a bobbin 70 according to the embodiment of FIG. picture). The drafting device 1 is downstream of a ring spinning machine 200 with a plurality of apron drafting units 204 (only one of which is shown), each of which feeds a bobbin 70 with a fiber sliver FB'. The ring spinning machine 200 produces the yarn G which is likewise wound on a bobbin 290 from the sliver FB′. According to the invention, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com