Program control operation mechanism for a hand dropping flow-following gestating device

A technology of flow inoculation device and operating mechanism, which is applied in the field of machinery to achieve the effect of reliable performance and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

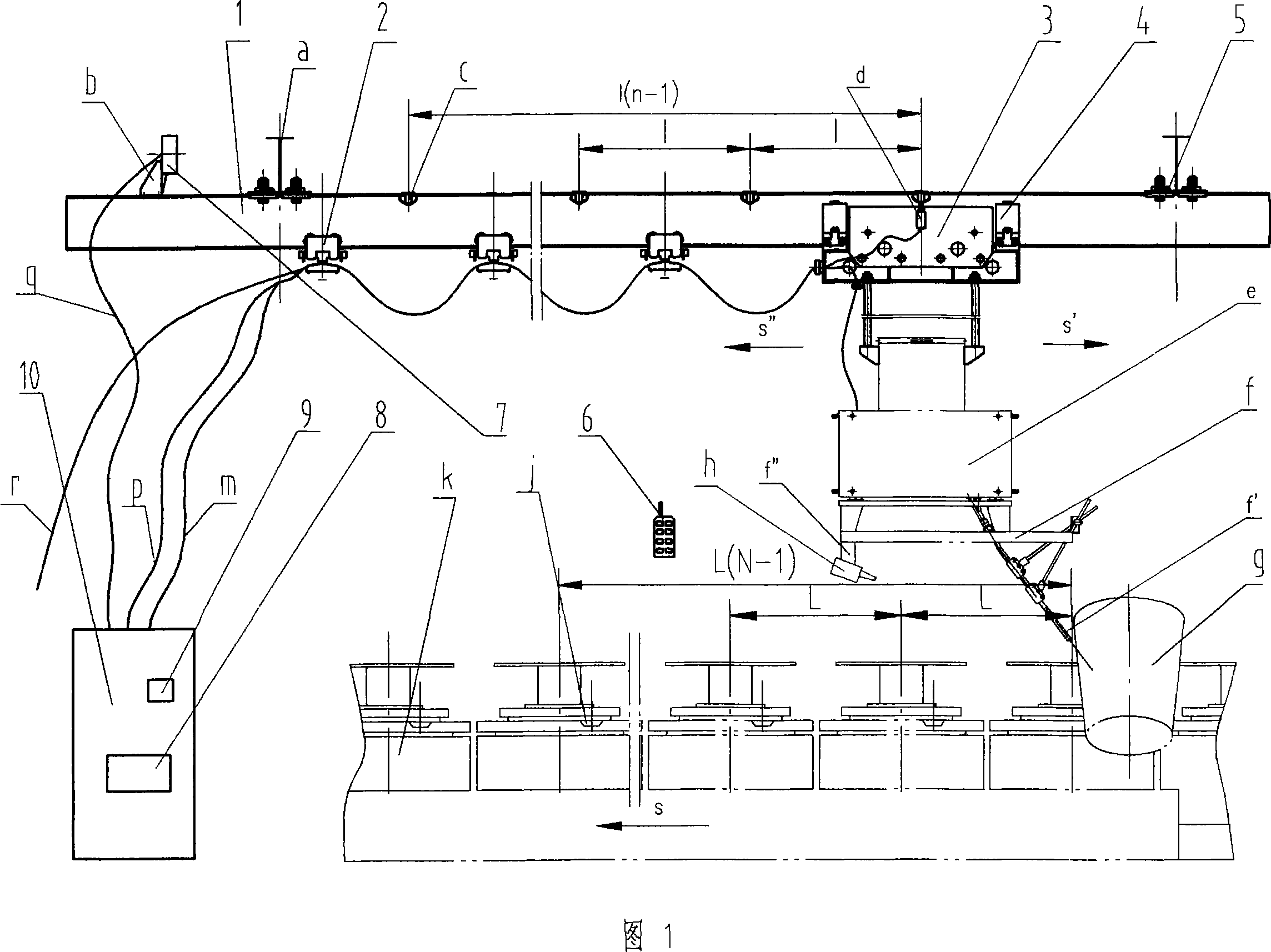

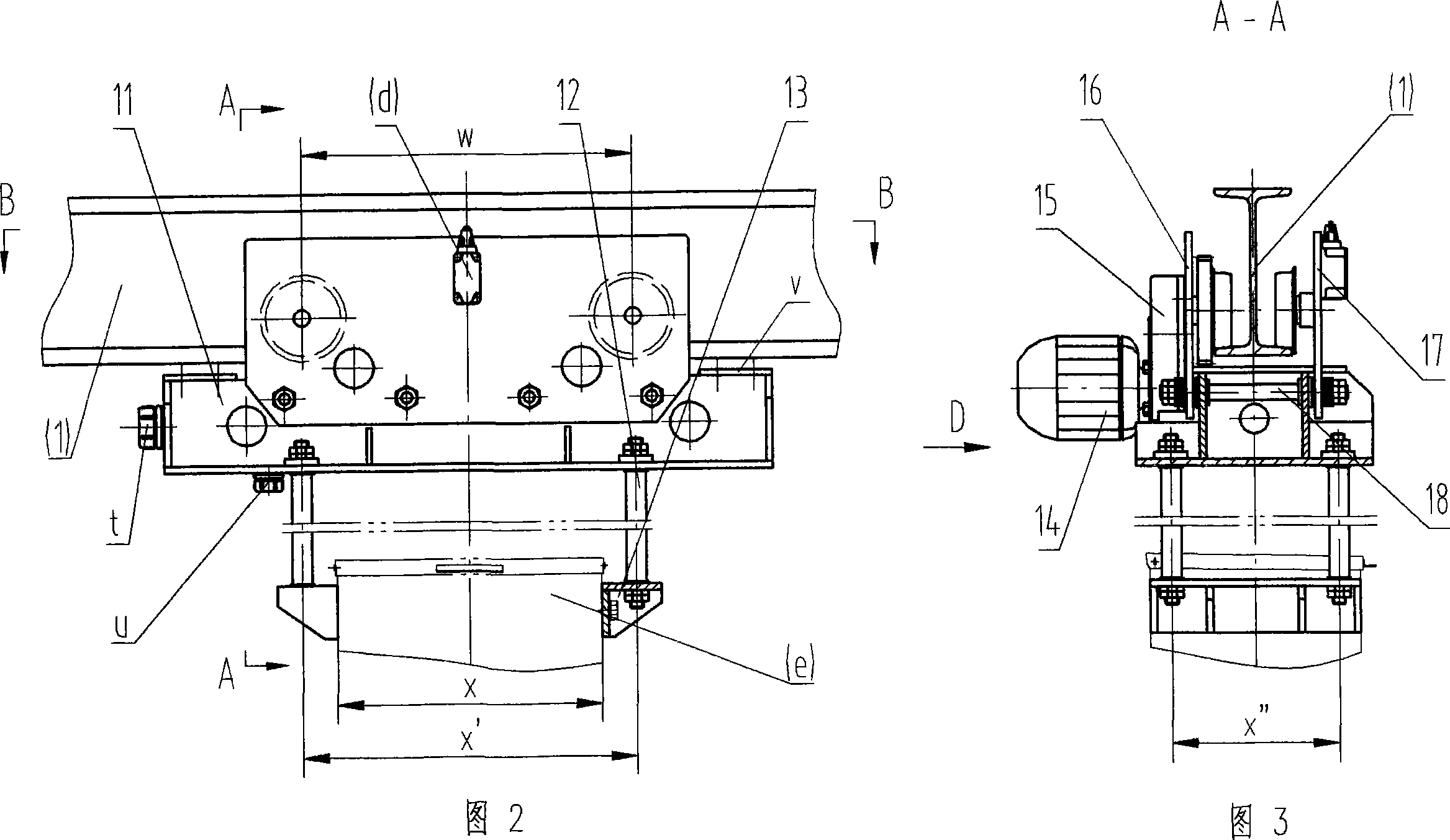

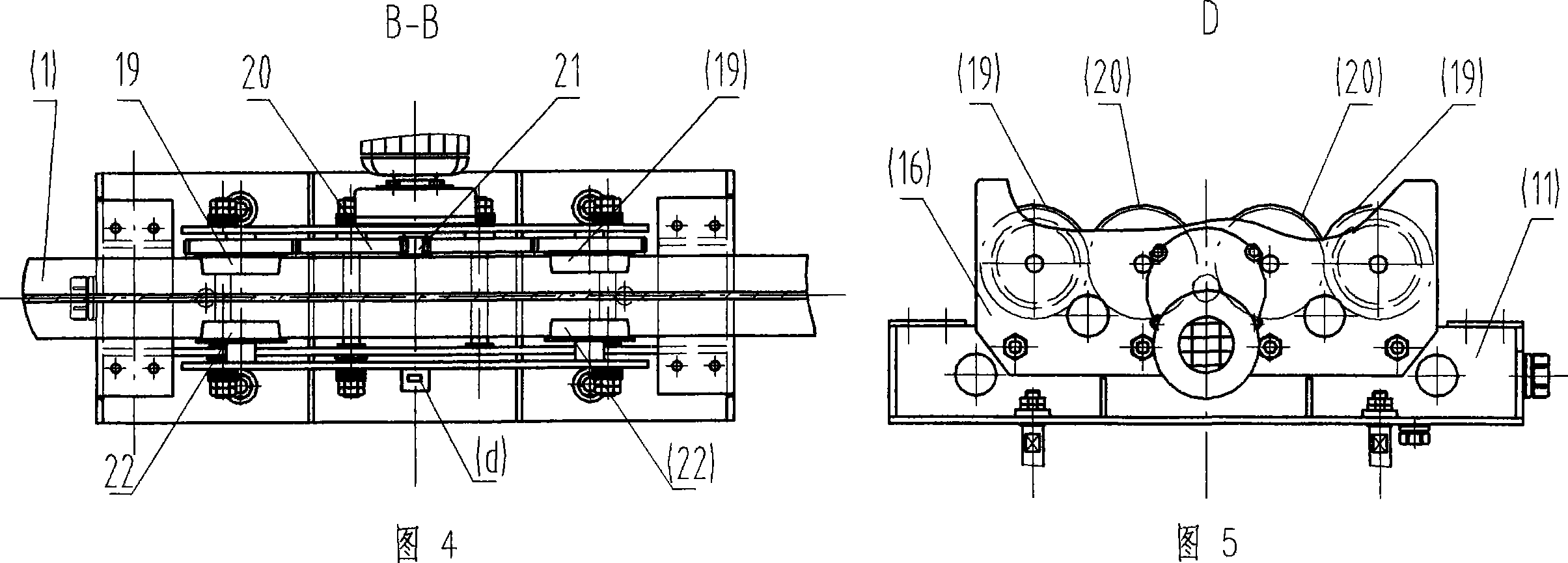

[0026] An example is used to illustrate its specific implementation.

[0027] As can be seen from Figure 1, a program-controlled operating mechanism for a manual pouring inoculation device includes an I-beam running track assembly 1, a cable pulley 2, a running trolley 3, four adjustable wheel assemblies 4, a track pressing plate assembly 5, and a remote control Transmitter 6, remote control receiver 7 and control cabinet 10. The I-steel running track assembly 1 is connected with the external steel frame support structure a through the track pressing plate assembly 5 provided on it; the running trolley 3 is placed on the I-steel running track assembly 1; four adjustable wheel assemblies 4 Connected to the upper end of the left and right parts of the running trolley 3, and located two by two on both sides of the I-steel waist in the I-steel running track assembly 1; the remote control receiver 7 is connected to the upper left side bracket b of the I-steel running track assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com