Measurement mechanism and measurement method for crankshaft assembly dynamic poise

A technology of measuring device and measuring method, which is applied in the direction of measuring device, static/dynamic balance test, machine/structural component test, etc., can solve the problems of not being able to meet the fast and precise inspection well, and spend a lot of labor, and save time. The effect of reducing labor and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

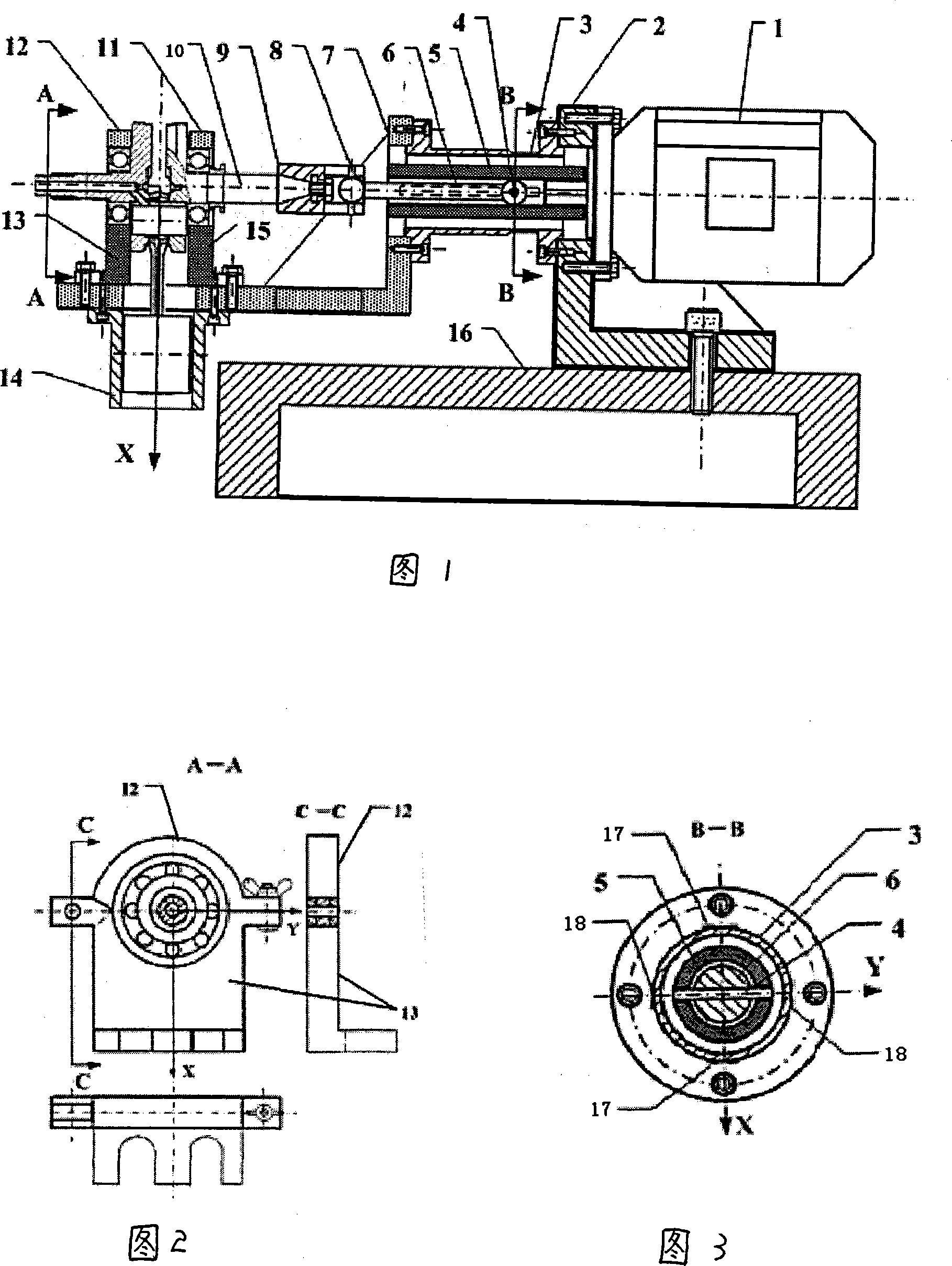

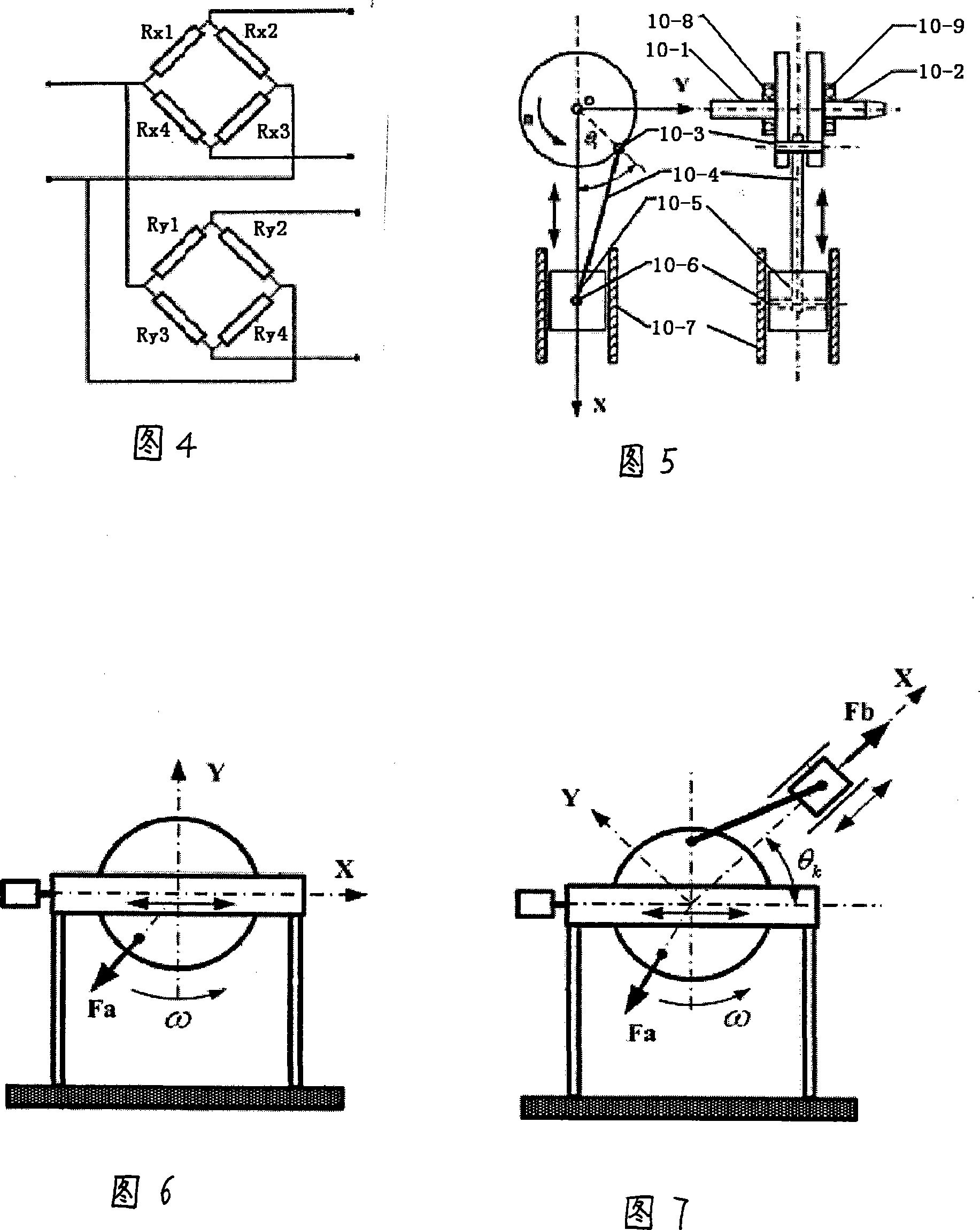

[0016] Referring to Fig. 1-Fig. 3, a measuring device for dynamic balance of a crankshaft assembly, the device includes a motor 1, a rectangular support seat 2, a cylindrical elastic support 3 with flanges at both ends, a hollow shaft sleeve 5, and a transmission shaft 6 , L-shaped bracket 7, connecting sleeve 9 and dynamic balancing machine bed 16, wherein: the right-angled support seat 2 is fixed on the dynamic balancing machine bed 16, and one end of the cylindrical elastic support 3 with flanges at both ends is fixed on the right-angled support On the vertical wall plate of the seat 2, there is a hole in the center of the wall plate, and the motor 1 is fixed on the other side opposite to the wall plate, and the L-shaped bracket 7 is fixed on the other end of the elastic support 3 of the hollow cylinder to form a cantilever; The shaft of 1 connects the hollow shaft sleeve 5 and the transmission shaft 6, and passes through the wall plate hole and the center of the inner hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com