Vapor sensor and materials therefor

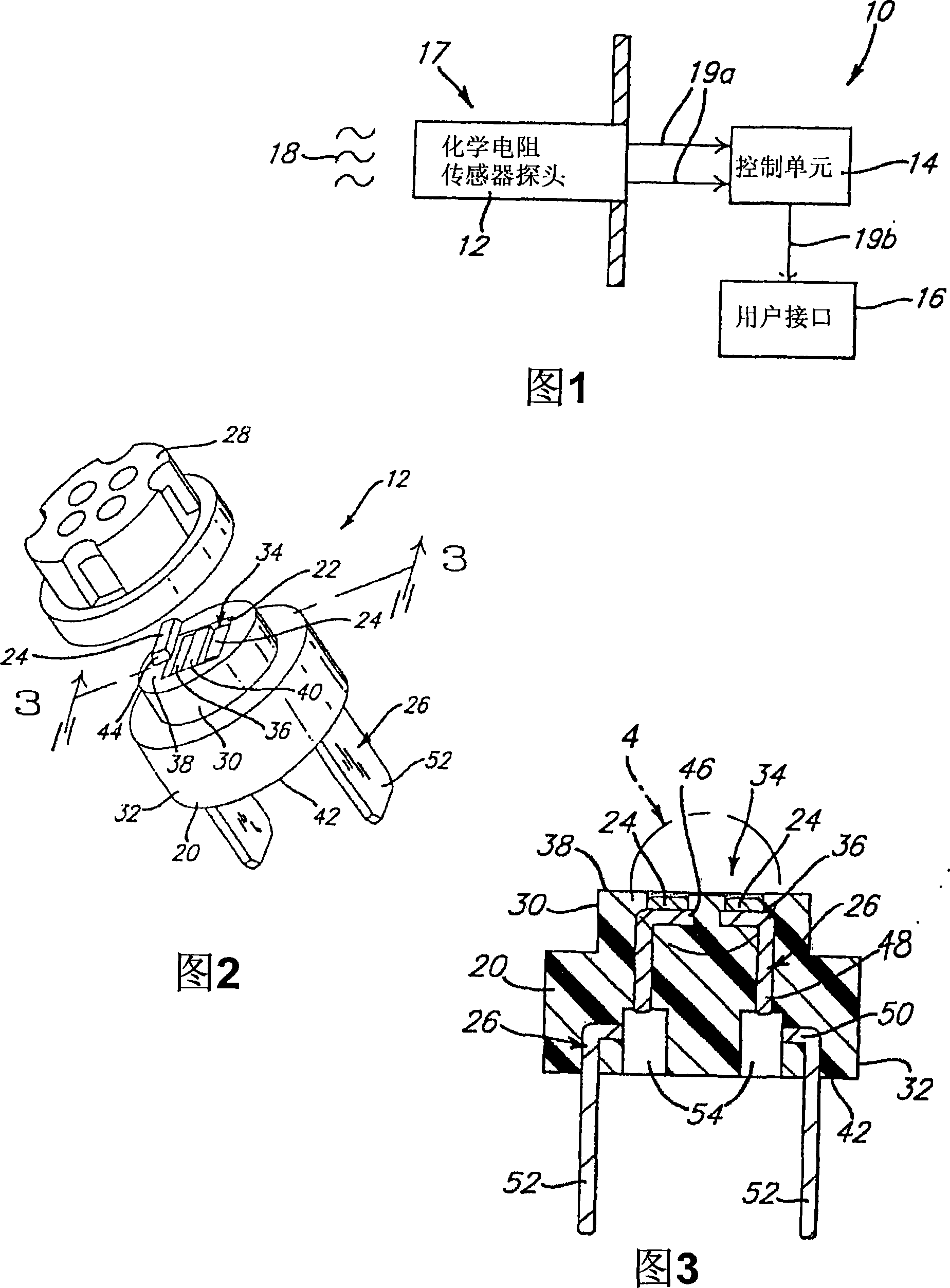

A sensor, conductivity sensor technology, applied in the analysis of materials, material resistance, material analysis by electromagnetic means, etc., can solve problems such as the need for low-resistance sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

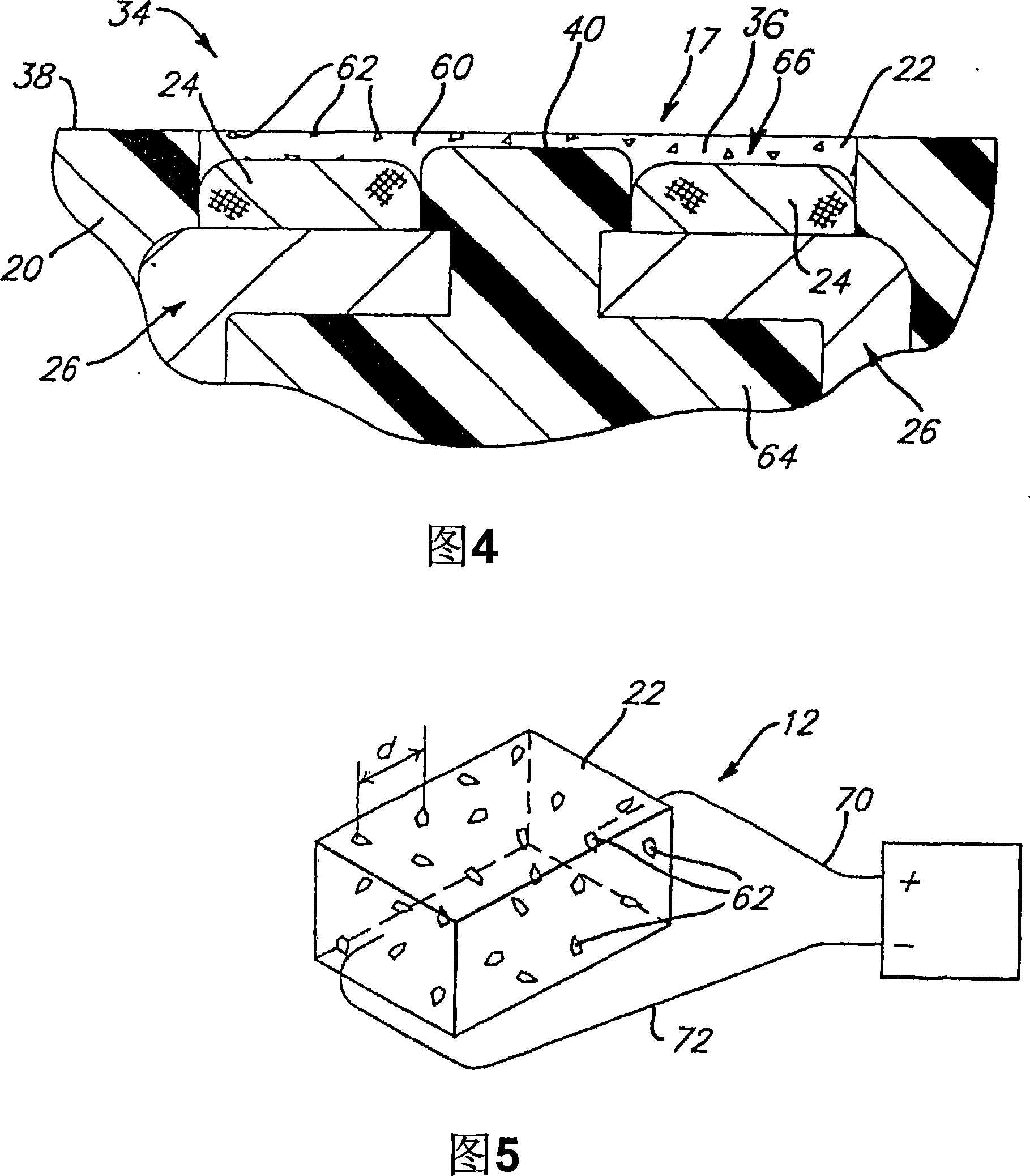

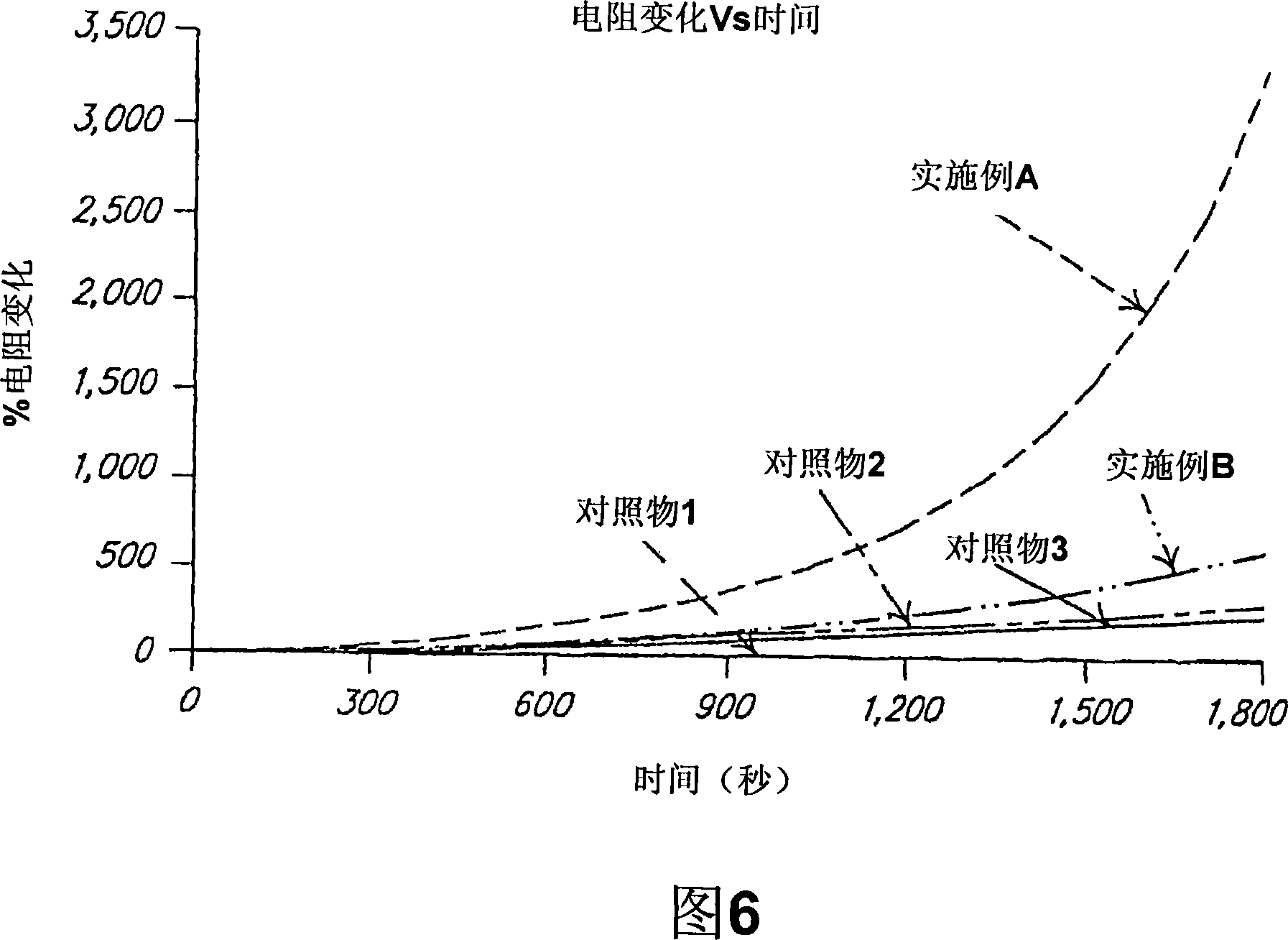

Embodiment 1

[0075] Add the following materials to the mixer: 4.45 grams of VAT-4326 (3-5% vinyl methicone) / (45-52% octyl methicone) / (dimethyl methicone) terpolymer, 3.23 g (7-13% hydroxymethyl siloxane) / (87-93% octyl methicone) copolymer, 19.31 g Asahi15HS (obtained from Asahi Carbon Company The large particle size carbon black, its N 2 Value is 14m 2 / g, and DBP is 85ml / 100g), 4.46 grams of C10 M250 UNS (ground carbon fiber from SGL Carbon Group) and 0.08 grams of SIP 6829 (platinum carbonyl cyclovinylmethylsiloxane catalyst complex), prepared A sensor film having a cross-linked large pendant hydrocarbyl substituted siloxane polymer matrix in which the first conductive particle species is large particle size conductive carbon black and the second species is carbon fiber. These materials were mixed in a Brabendel(R) stick machine at 80 rpm for 15 minutes at 30°C to form a matrix mixture. The mixture is then coated into the grooves on the electrodes in the sensor structure. The sensor ...

Embodiment 2

[0077] The following materials were added to the mixer: 0.11 grams of VAT-4326 (3-5% Vinylmethylsiloxane) / (45-52% Octylmethicone) / (Dimethicone) from Gelest methicone) terpolymer, 10.3 g (7-13% hydroxymethyl siloxane) / (87-93% octyl methicone) copolymer, 18.5 g Asahi 15HS (White Asahi Carbon Company's large particle size carbon black, its N 2 Value is 14m 2 / g, and DBP is 85ml / 100g), 4.0 grams of 210 type nickel (210 type fine nickel powder from Inco Ltd., a subsidiary of Novamet), and 0.086 grams of SIP 6829 (platinum carbonyl cyclovinylmethylsiloxane catalyst Composite) to prepare a sensor film having a cross-linked large-side hydrocarbyl-substituted siloxane polymer matrix, the first conductive particle species in the polymer matrix is large-diameter conductive carbon black, and the second species includes nickel. These materials were mixed in a Brabender(R) mixer at 80 rpm for 15 minutes at 30°C to form a matrix mixture. The mixture is then coated into the grooves on th...

Embodiment 3

[0079] The following materials were added to the mixer: 0.11 grams of VAT-4326 (3-5% Vinylmethylsiloxane) / (45-52% Octylmethicone) / (Dimethicone) from Gelest methicone) terpolymer, 10.2 g (7-13% hydroxymethyl siloxane) / (87-93% octyl methicone) copolymer, 18.4 g Asahi 15HS (obtained from AsahiCarbon Company The large particle size carbon black, its N 2 Value is 14m 2 / g, and DBP is 85ml / 100g), 4.6 grams of 210 type nickel (210 type fine nickel powder from Inco Ltd., a subsidiary of Novamet), and 0.085 grams of SIP 6829 (platinum carbonyl cyclovinylmethylsiloxane catalyst Composite) to prepare a sensor film having a cross-linked large-side hydrocarbyl-substituted siloxane polymer matrix, the first conductive particle species in the polymer matrix is large-diameter conductive carbon black, and the second species includes nickel. These materials were mixed in a Brabender(R) mixer at 80 rpm for 15 minutes at 30°C to form a matrix mixture. The mixture is then coated into the groo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com