Repair circuitry and method for preventing electrical fuse from being burned during static discharge testing

A technique for electrostatic discharge testing and repairing circuits, applied to circuits, electrical components, static memory, etc., to achieve the effect of avoiding programming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

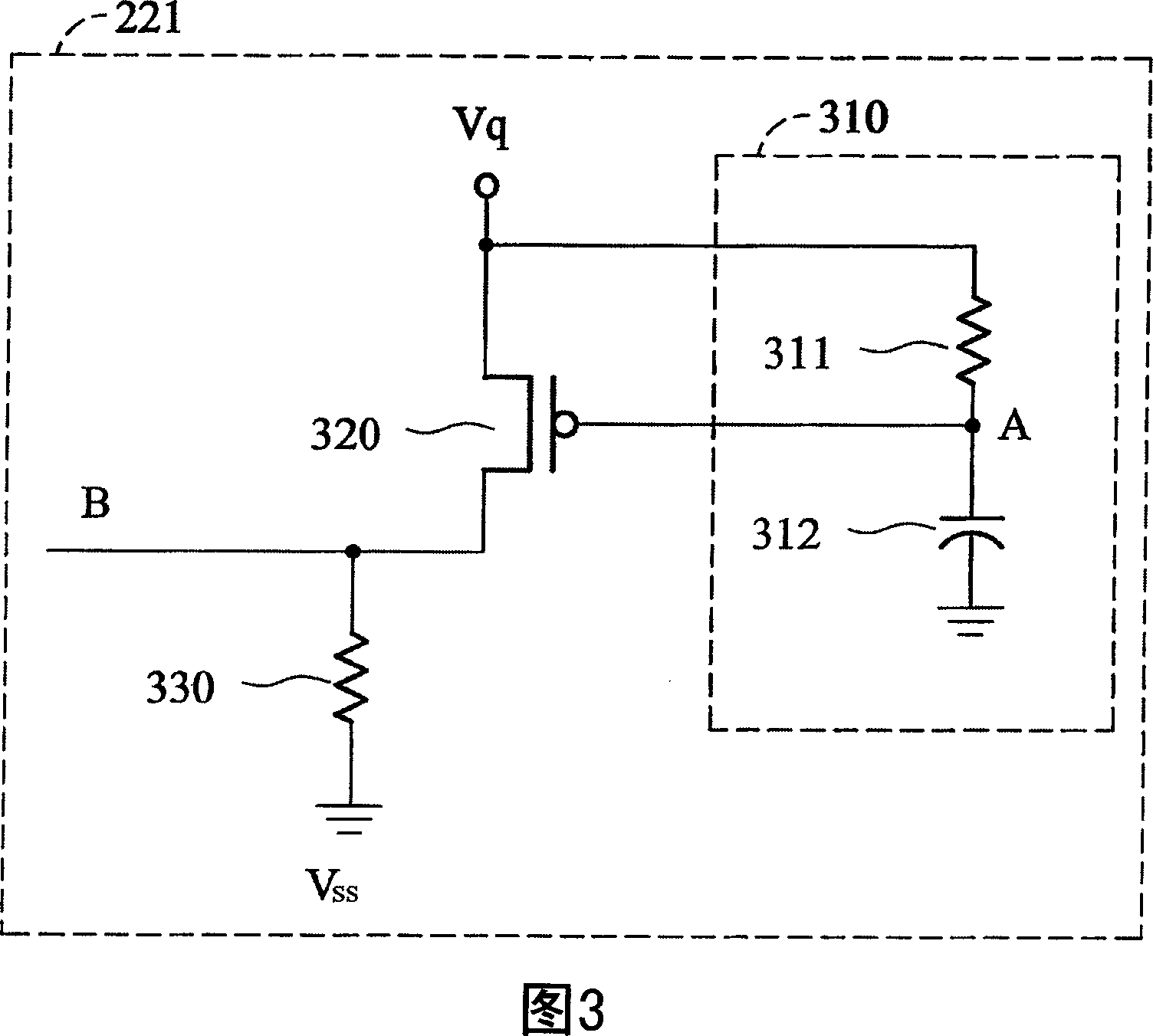

[0038] Since e-fuse is widely used in integrated circuits, a robust e-fuse circuit can effectively improve the overall SoC yield. In a generalized embodiment, the present invention provides an improved repair circuit for storing IP cores having at least one switching device and at least one control circuit to prevent e-fuse from being deliberately programmed, thereby improving overall SoC yield.

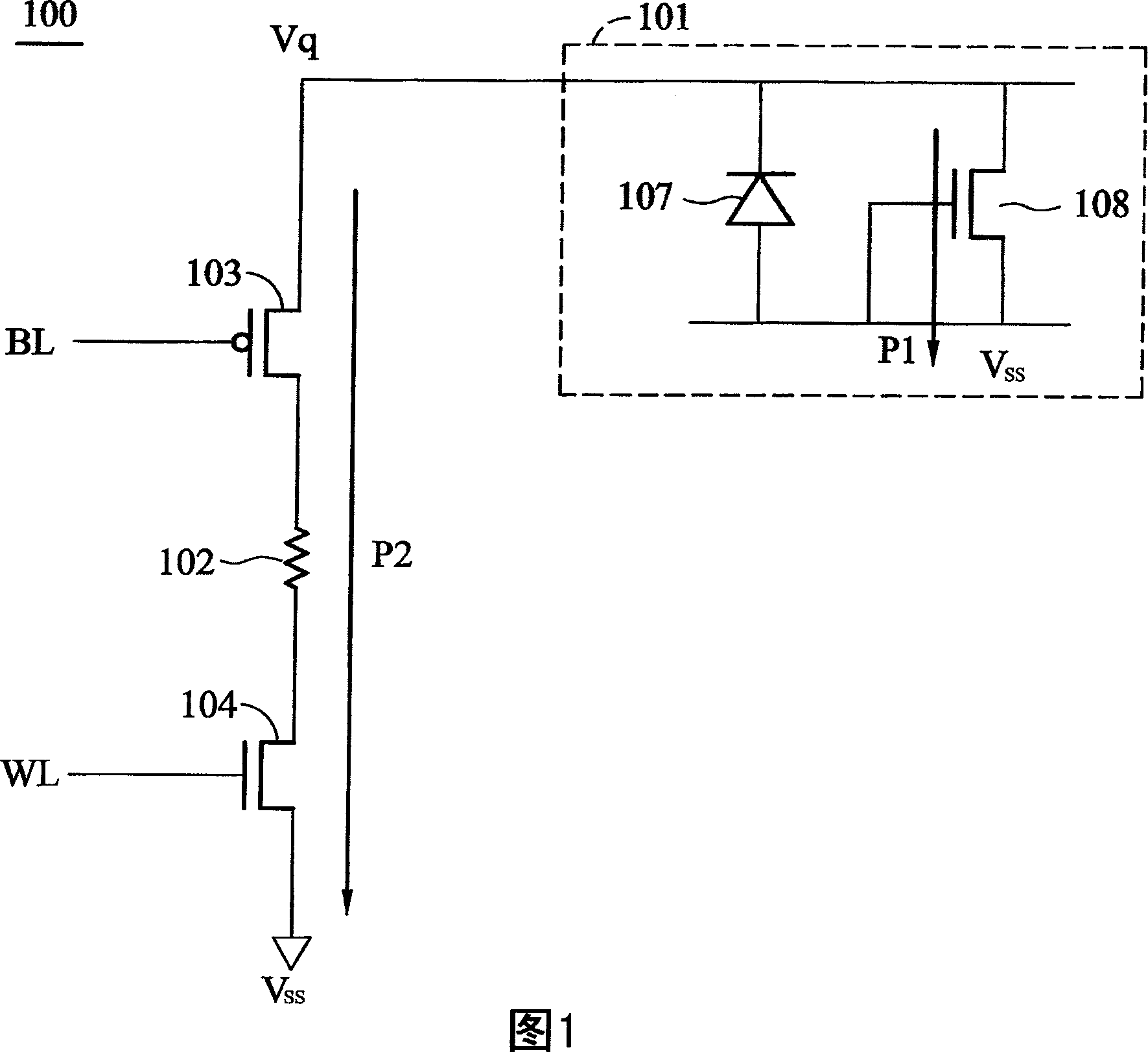

[0039] Figure 1 has been described and discussed in the Background of the Invention. No further discussion is required here.

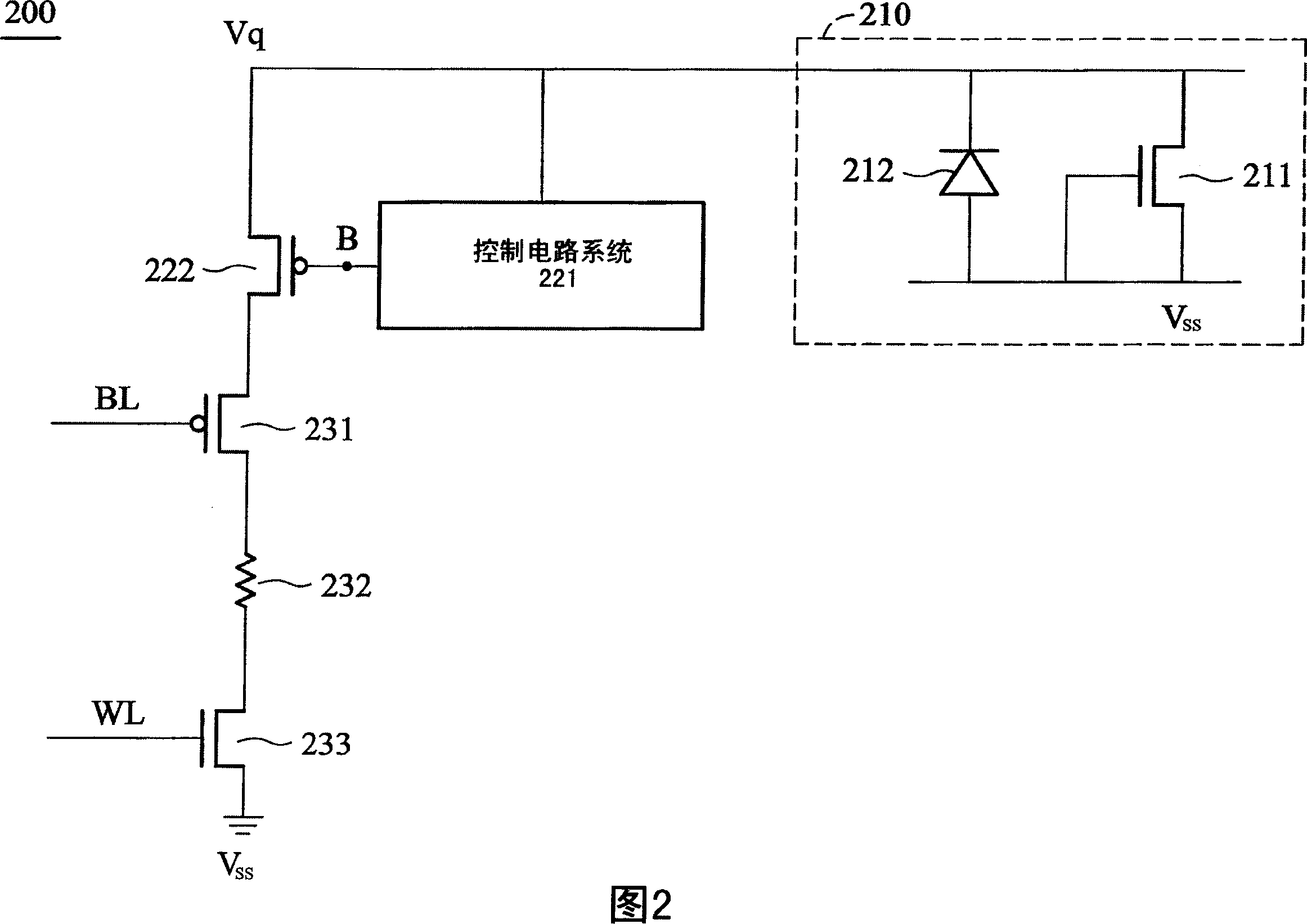

[0040]Figure 2 shows a repair circuit 200 with improved ESD protection in accordance with a preferred embodiment of the present invention. In addition to the ESD clamping circuit 210 including two diodes 211 and 212 , the improved repairing circuit 200 also includes a switching device 222 and a control circuit system (or referred to as a control circuit) 221 .

[0041] In FIG. 2, the embodiment has at least one electronic fuse 232 forming at least one condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com