Semi-conductor silicon chip liquid stage source diffusion furnace

A diffusion furnace and liquid source technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of low production efficiency and poor diffusion uniformity, achieve high production efficiency, uniform diffusion, and solve the problem of uneven diffusion of gas sources. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings.

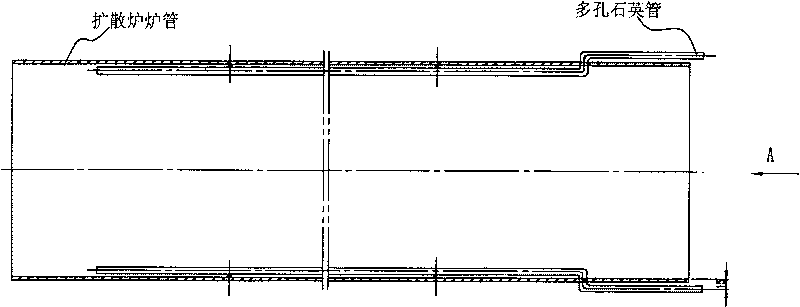

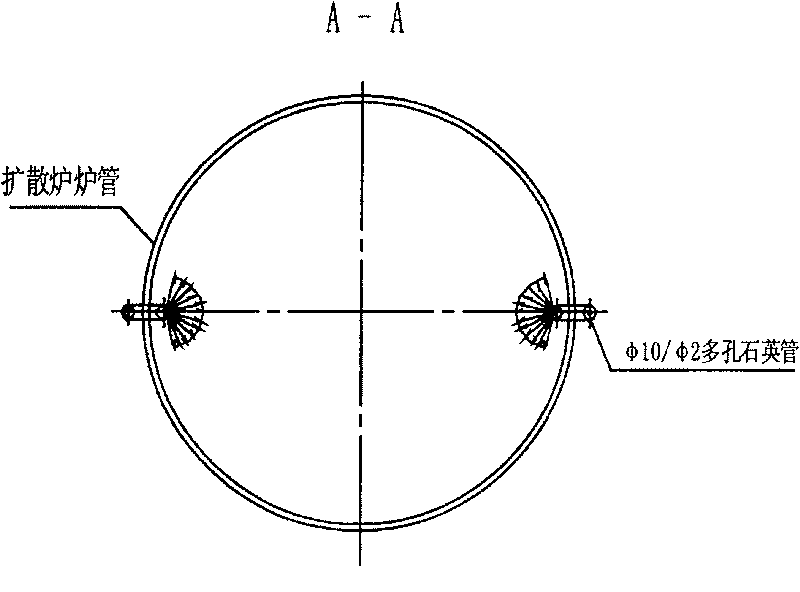

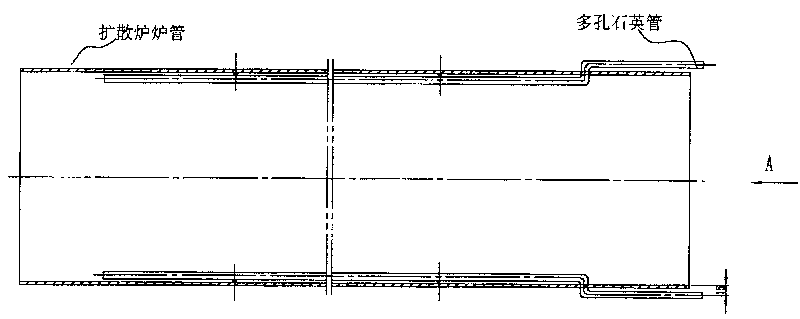

[0010] figure 1 It is a schematic diagram of the semiconductor silicon wafer liquid source diffusion furnace structure of the present invention, figure 2 yes figure 1 A view from direction A.

[0011] As shown in the figure, the semiconductor silicon wafer liquid source diffusion furnace of the present invention has an open structure at both ends, and the product can be uniformly doped during the movement of one end and the other end. On the inner wall of the furnace tube are installed 2 to 10 spray source quartz tubes with a diameter of φ2 to φ10mm. The walls of the spray source quartz tubes are distributed with capillary holes of uniform size. The source bottle for the diffusion source. When the source bottle has a certain vapor pressure, the gas carrying the source enters the quartz tube from the source bottle, and enters the diffusion furnace tube th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com