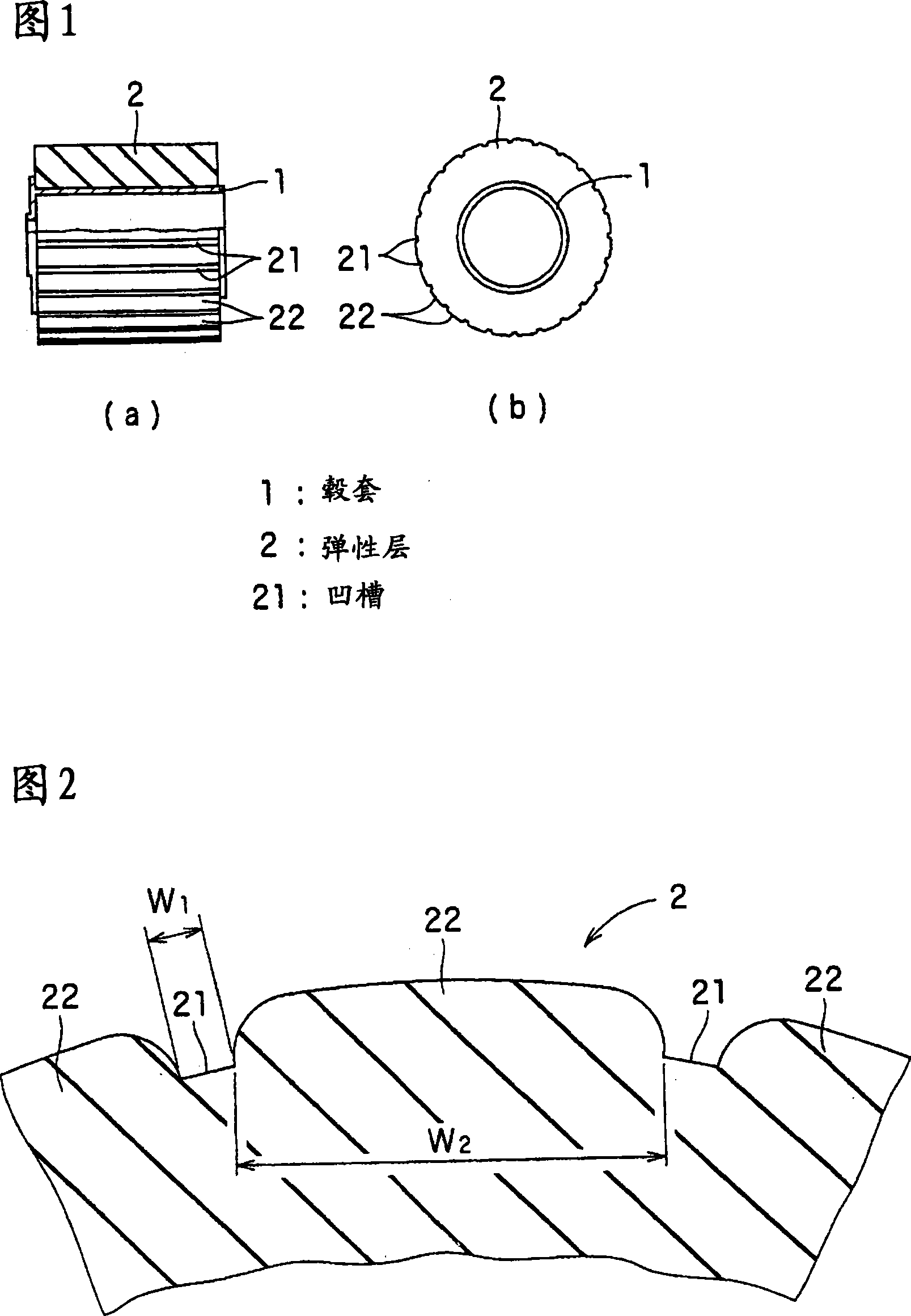

Sheet feed roller and method of manufacturing the same

A paper feeding and elastic layer technology, which is applied to the electrical recording process using charge graphics, equipment for electrical recording technology using charge graphics, pile separation, etc., can solve the problem of higher maintenance costs and shorter replacement cycles for paper feeding rollers and other problems, to achieve the effect of lengthening the maintenance time, improving the conveying capacity, and improving the handling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、2、2

[0041] [embodiment 1,2,2 ', 2 " and experimental example 1,2 and comparative example 1,2]

[0042] [Preparation of elastic layer forming material (uncrosslinked thermosetting polyurethane rubber)]

[0043] 70 parts by weight of polytetramethylene ether glycol (PTMG), polypropylene glycol (PPG) [Preminol S 3005 manufactured by Asahi Glass Co., Ltd. (monohydric alcohol content: 0.8% by weight, Mn: 5000, number of functional groups: 3, total unsaturated Degree: 0.0048meq / g)] 30 parts by weight, after vacuum defoaming and dehydration at 80°C for one hour, mix an appropriate amount of polyisocyanate [toluene diisocyanate (TDI)], and make it react at 80°C for three hours under a nitrogen atmosphere , to prepare a polyurethane prepolymer (NCO content: 3.0% by weight, NCO index: 105) having an NCO group at the terminal. And, after vacuum defoaming the polyurethane prepolymer at 90° C. for 30 minutes, 1.8 parts by weight of chain extender [1,4-butanediol (1,4-BD)], chain extender [tri...

Embodiment 3~6

[0053]In the adjustment of the forming material of the elastic layer in the above-mentioned Examples 1, 2, 2', 2" and Experimental Examples 1 and 2, the weight ratio (PTMG / PPG) of the mixed PTMG and PPG was obtained as shown in Table 3 below PPG), change the JIS-A hardness of the formed elastic layer in each example. Other than that, it is the same as the above-mentioned Example 1. In the following Table 3, this Example 1 is also shown together.

[0054] [existing example 1]

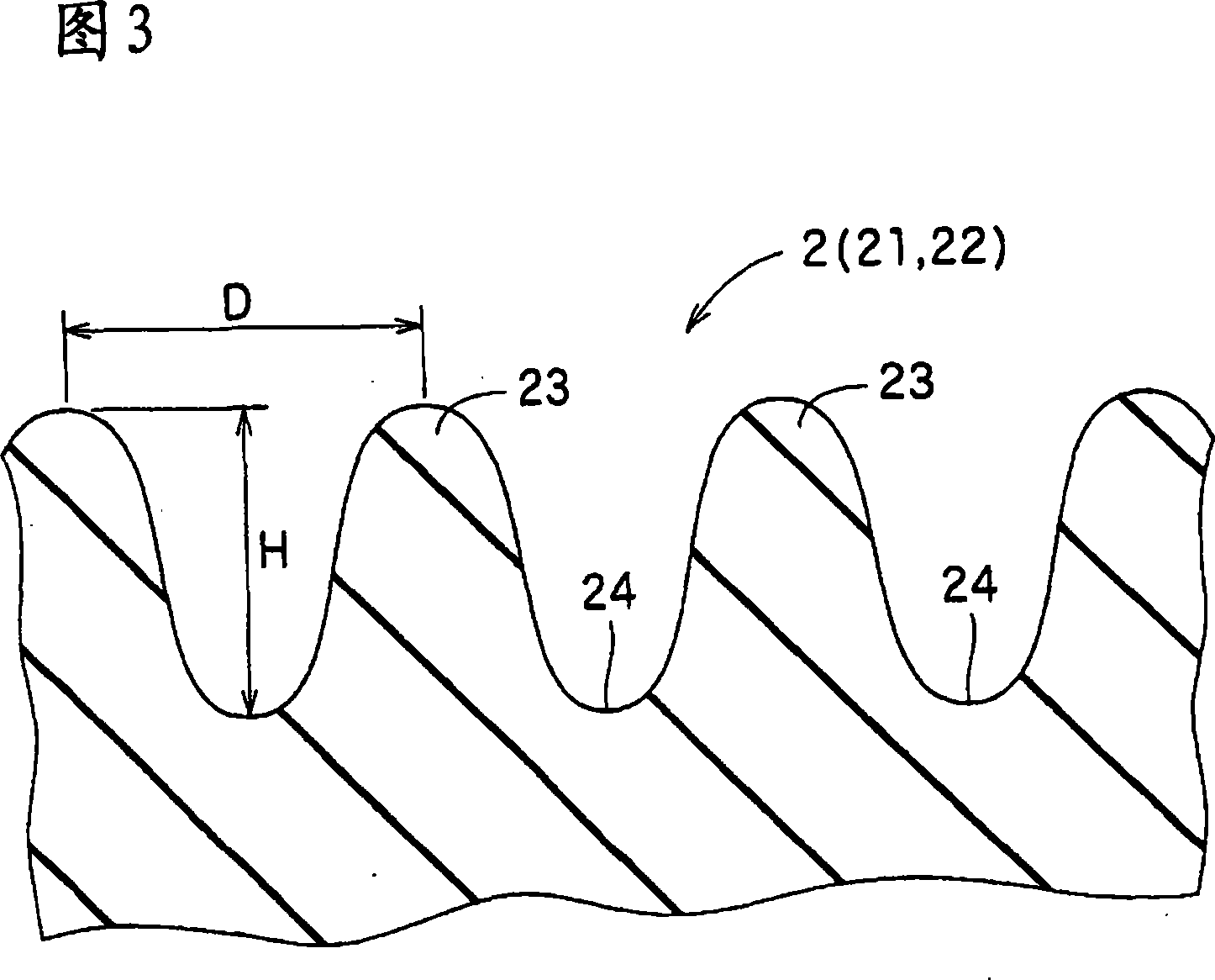

[0055] As a conventional example 1, a paper feed roller having an elastic layer made of polyurethane, a corrugated surface, and no grooves was used as a conventional product. The area of the mountain portion of the crepe surface (S 1 ) and valley area (S 2 ) to the area ratio (S 1 / S 2 ), the height of the mountain-shaped portion, and the distance between the tops of adjacent mountain-shaped portions were measured in the same manner as above, and the results are shown in Tables 1 and 2 below.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com