Flash evaporation prevention valve

An anti-flash and valve technology, applied in the direction of valve lift, valve details, valve devices, etc., can solve the problems of poor pressure reduction effect, complicated manufacturing process, complex processing process, etc., to protect pipelines and other equipment, assembly process Simplicity and the effect of ensuring flow capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

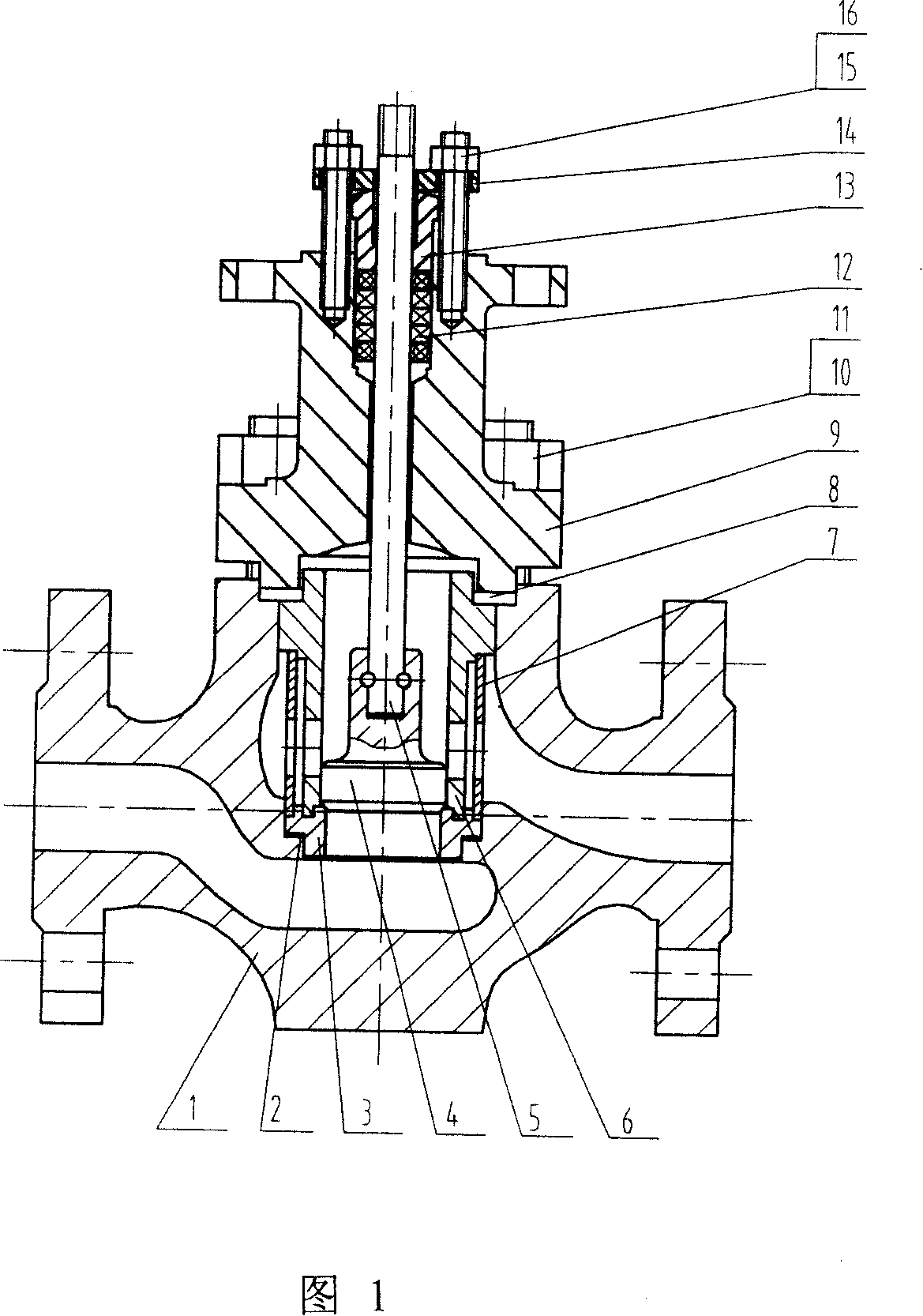

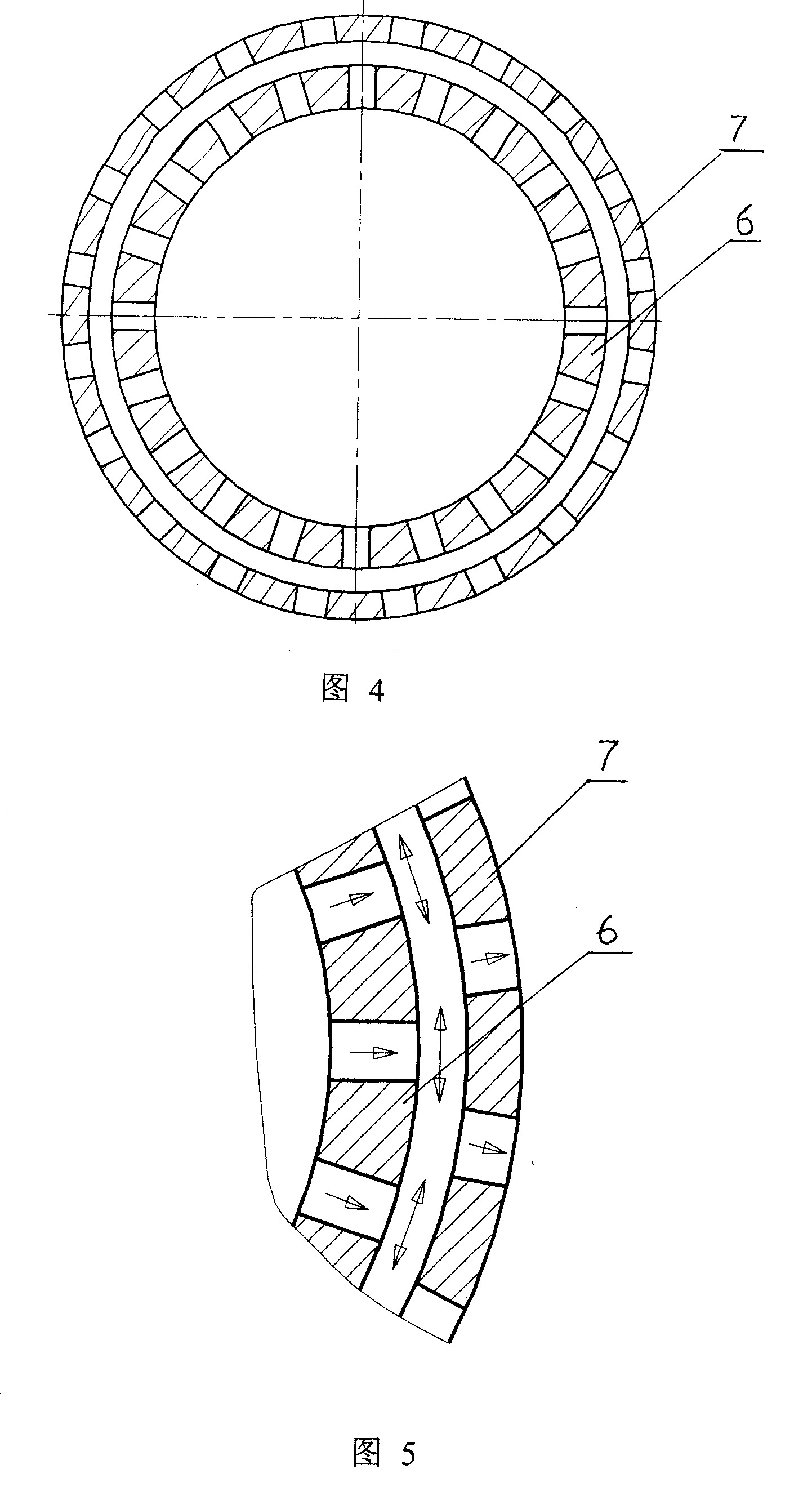

[0018] As shown in Figure 1, a kind of anti-flash valve, it comprises valve body 1 and valve cover 9, and valve seat 3, valve disc 4, valve stem 5 and anti-flash structure are installed in valve body 1, said The anti-flash structure is composed of at least two layers of sleeves arranged between the valve disc 4 and the valve body 1, and a throttling window is opened on the circumferential wall of each layer of sleeves. Stagger installation at a certain angle.

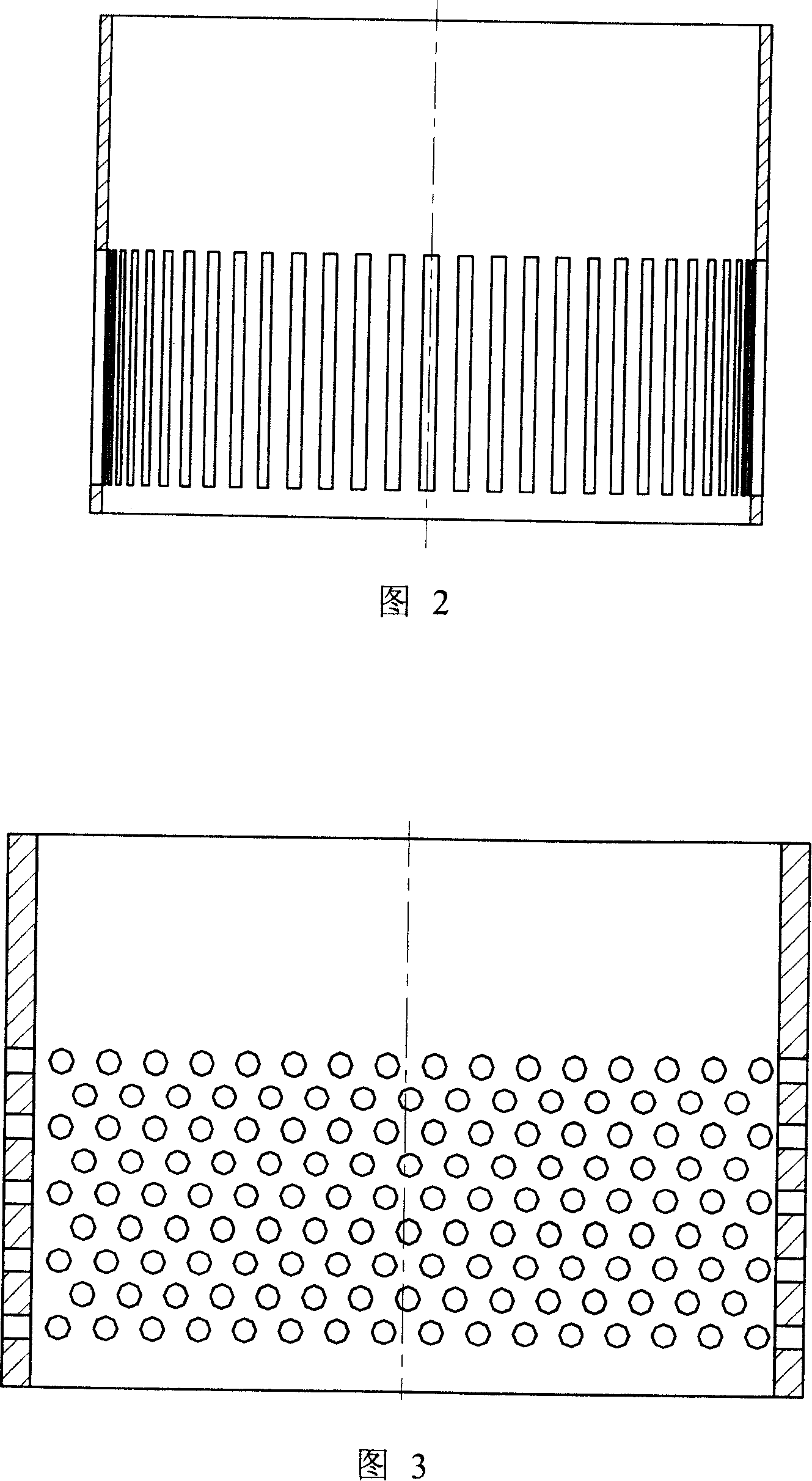

[0019] The sleeve in this embodiment has only 2 layers, that is, the inner sleeve 6 and the outer sleeve 7. In practical applications, if the working conditions require, it can be designed as a 3-layer or more layer sleeve. There is a certain gap, so that the fluid collides, merges, and diverges in the gap, and then flows to the next layer of sleeve after the pressure is reduced, until the outlet drops to the pressure required by the process, and the pressure drop of each stage is less than the critical value of flashin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com