Full-automatic thermal storage electric boiler

A fully automatic technology for electric boilers, applied in the field of electric boilers, can solve the problems of small heat release coefficient on the surface of electric heaters, slow heating speed, and inability to use refrigeration, etc., to increase the ability to convert waste heat again, and prevent corrosion and scaling. , the effect of accelerating the heating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

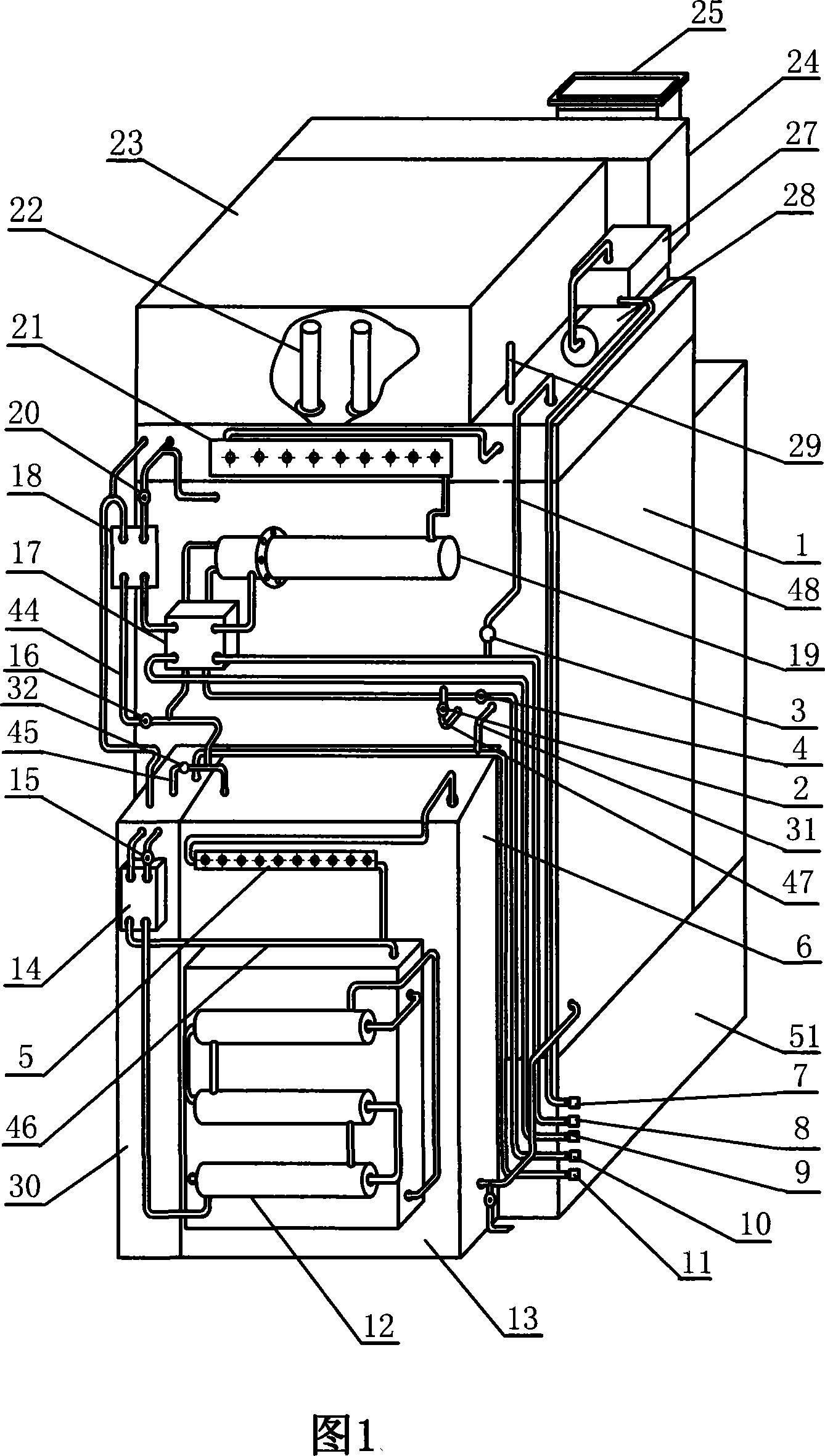

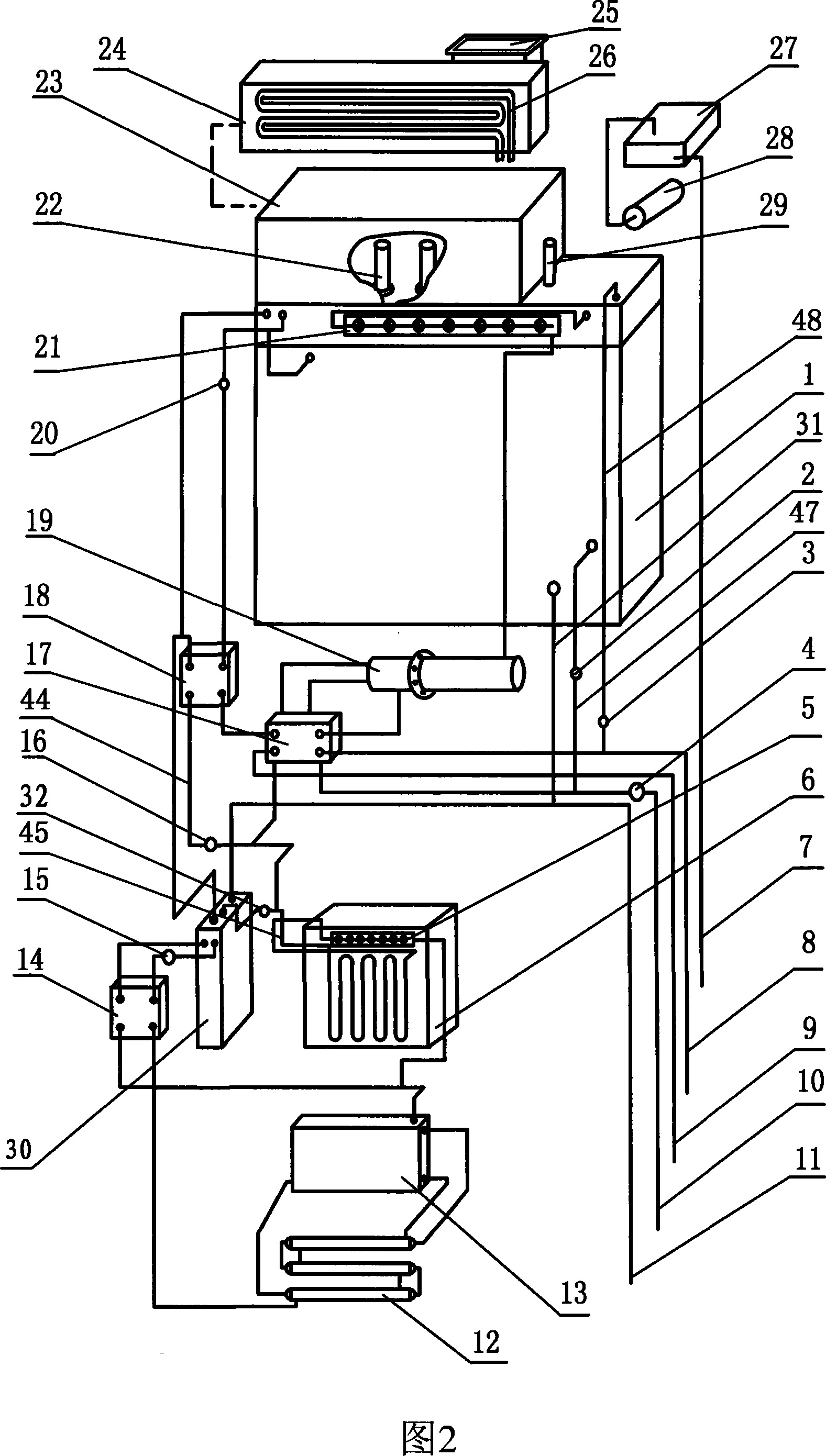

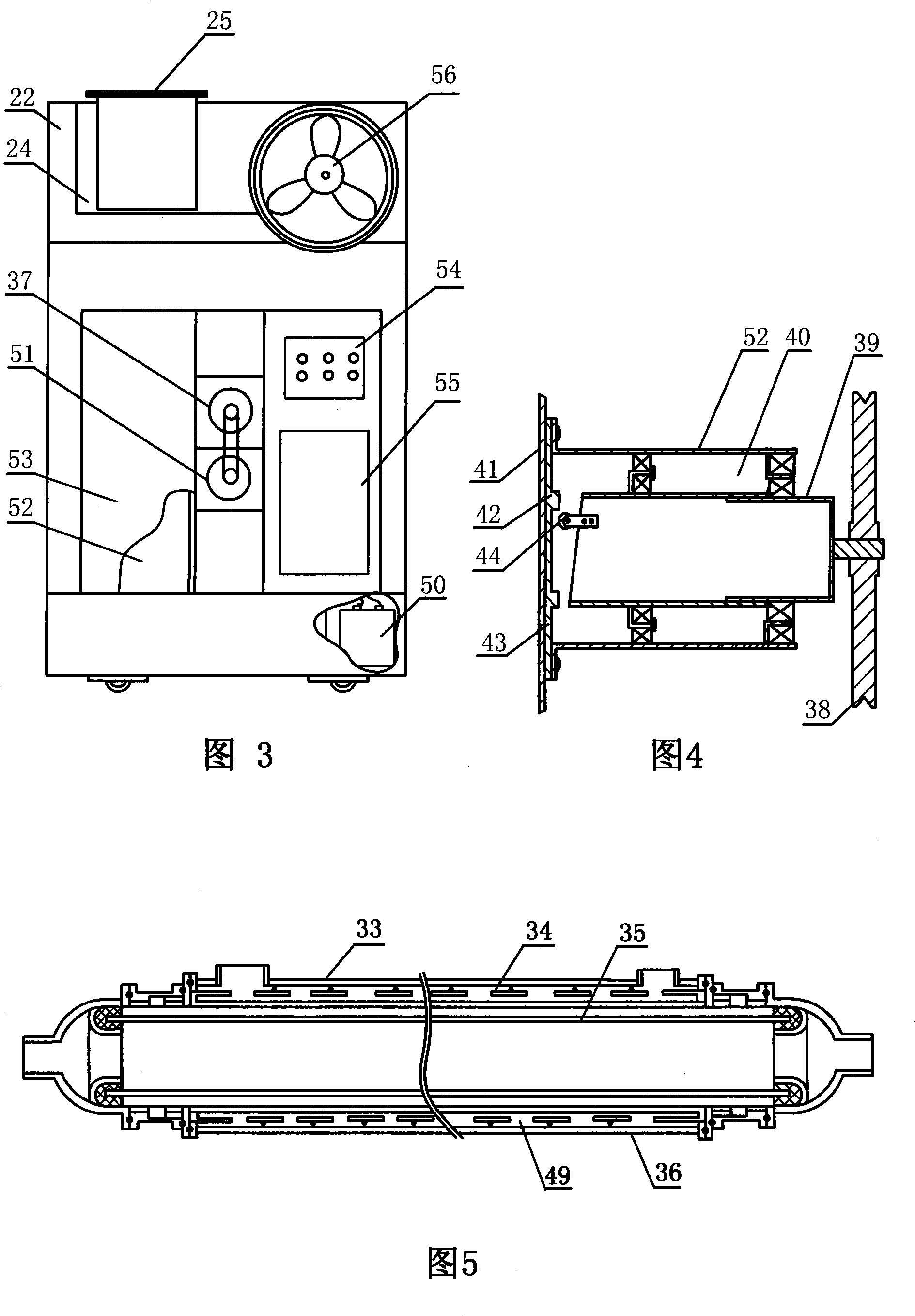

[0020] The fully automatic thermal storage electric boiler includes an electric heating device 12, a hot water storage device, a circulation system, an automatic electromagnetic valve and an automatic control system. The hot water storage device is composed of a rapid hot water storage tank 30 with a capacity of 5 kg, a waste heat hot water storage tank 6, and a hot water storage tank 1 for heating and heating. The inlets at both ends of the side of the rapid hot water storage tank 30 are respectively connected with the outlets at both ends of the lower heat exchanger 14, one end inlet of the lower heat exchanger 14 is connected with one end of the electric heating device 12, and the other end is The inlet is connected to the heat exchanger 13 connected to the electric heating device 12; one end above the fast water storage tank 30 is connected to the upper heat exchanger 18, and the middle end passes through a pipeline 45 with a heating electric valve 32 It is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com