Deep rock mass non-linear mechanics experimental equipment

A mechanical test and nonlinear technology, applied in scientific instruments, strength characteristics, measuring devices, etc., can solve problems such as frequency increase, degree intensification, and disaster mechanism complexity, and achieve the effect of saving space, saving materials and processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

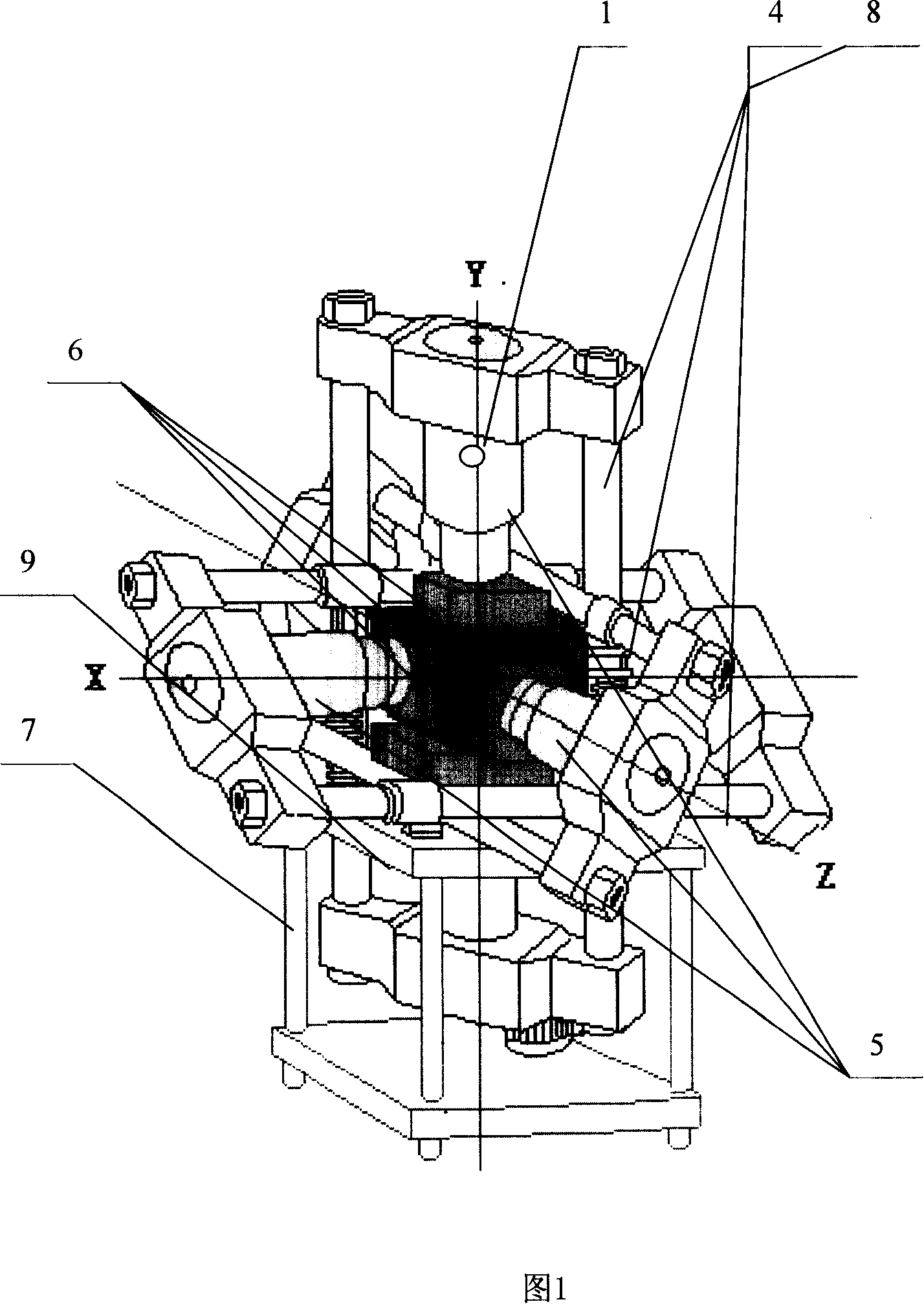

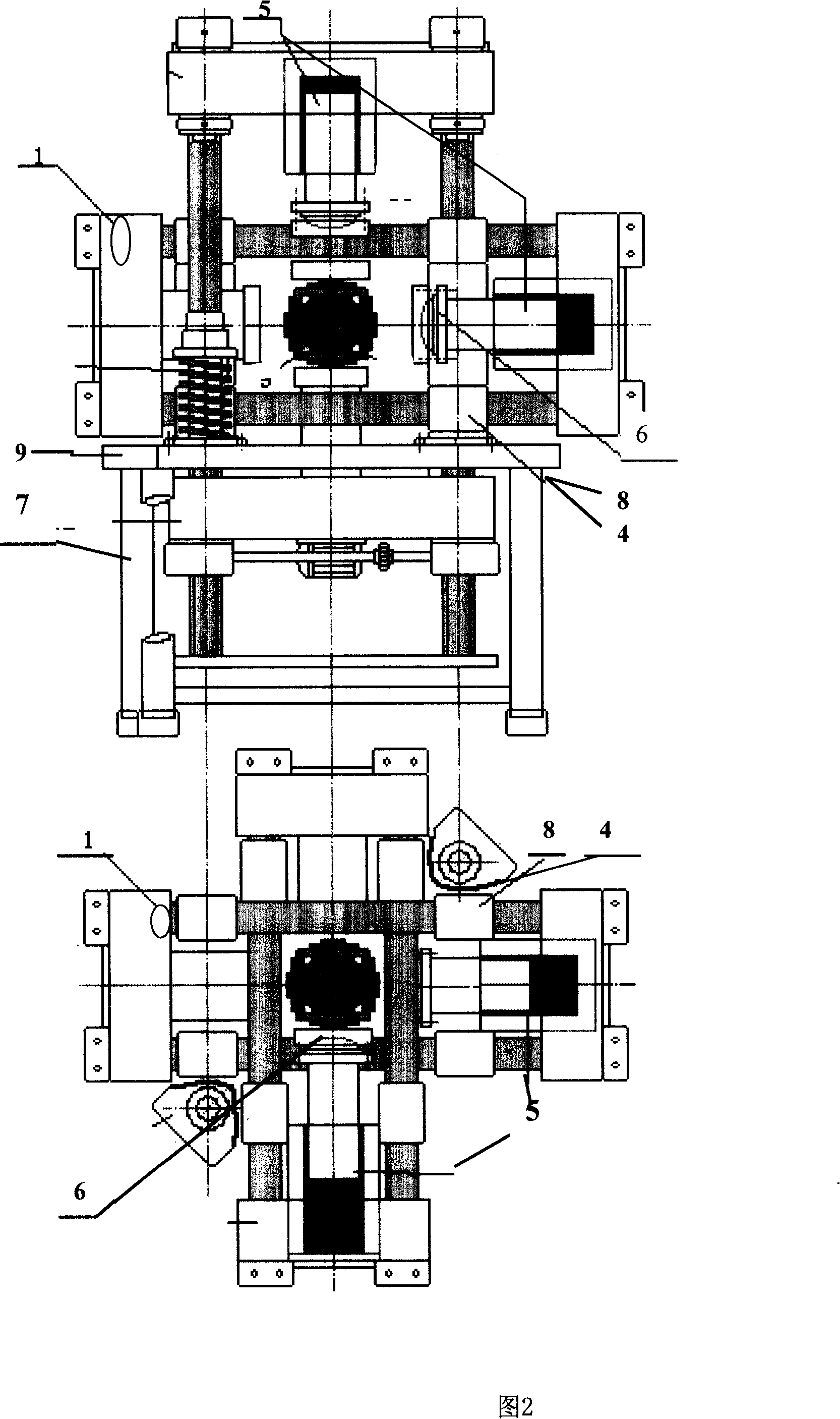

[0014] A deep rock mass nonlinear mechanics test equipment according to the present invention is composed of a test host 1, a hydraulic power and control device, and a data acquisition and analysis device. The hydraulic power and control device provides nonlinear hydraulic power and control for the host 1, The data acquisition and analysis device collects and analyzes data through the sensors installed on the host 1, hydraulic power and control device, and the host 1 is composed of the following parts:

[0015] 1) Rigid support structures 4 arranged in three-dimensional orthogonal axial directions, there should be a space between the corresponding rigid support structures 4 in each direction to install the hydraulic loading device 5 and enough space for its hydraulic cylinder to operate;

[0016] 2) Standing on the ground, the base 7 is rigidly and fixedly connected with the rigid support structure 4;

[0017] It is characterized in that: the main engine 1 also includes three ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com