Condenser type touch screen and preparation method thereof

A capacitive touch screen, touch screen technology, applied in the direction of electrical digital data processing, instruments, data processing input/output process, etc., can solve the problems of touch screen failure, signal influence, induction block conduction, etc., to reduce electromagnetic interference, improve Transmittance, the effect of avoiding Newton's ring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

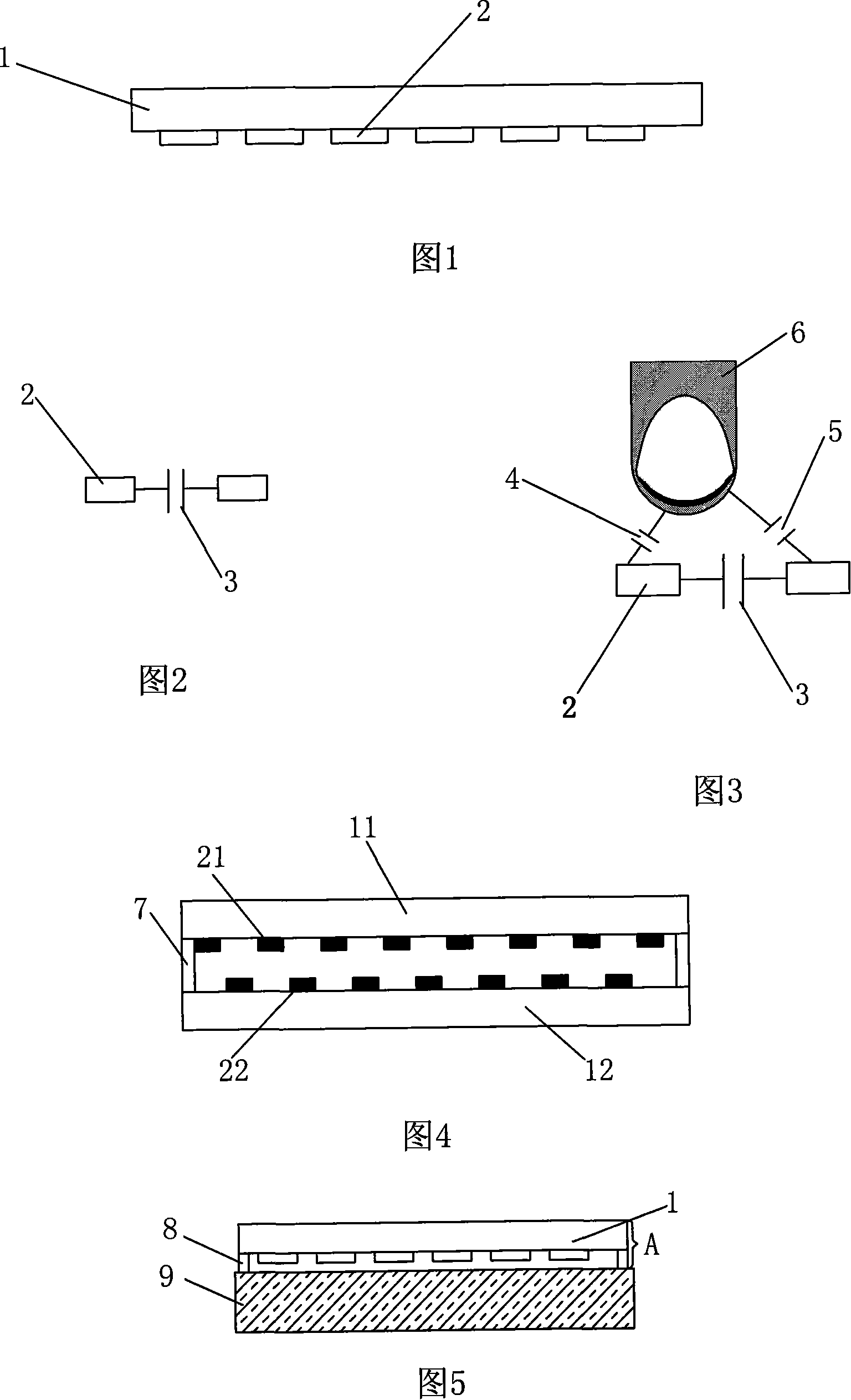

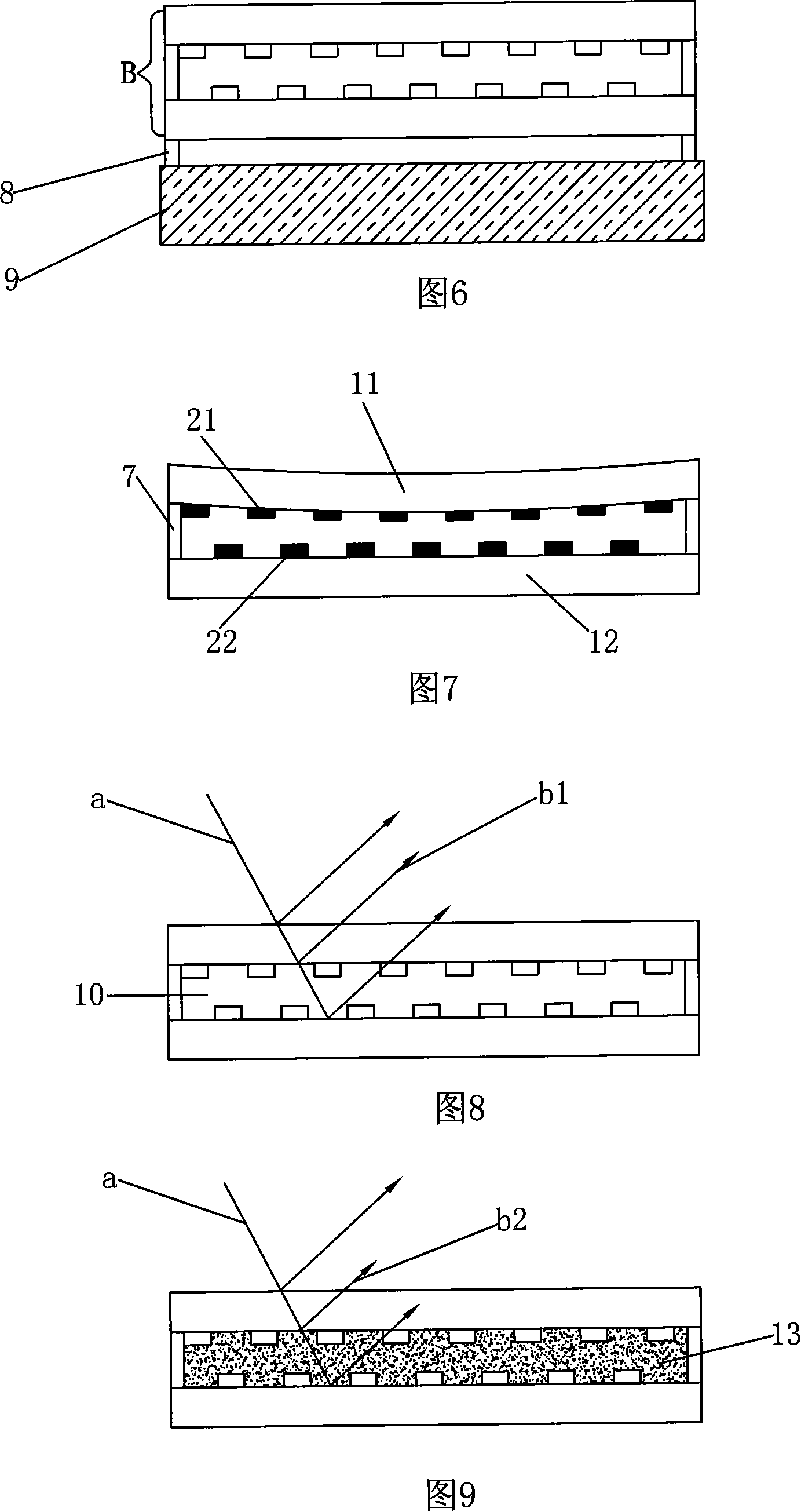

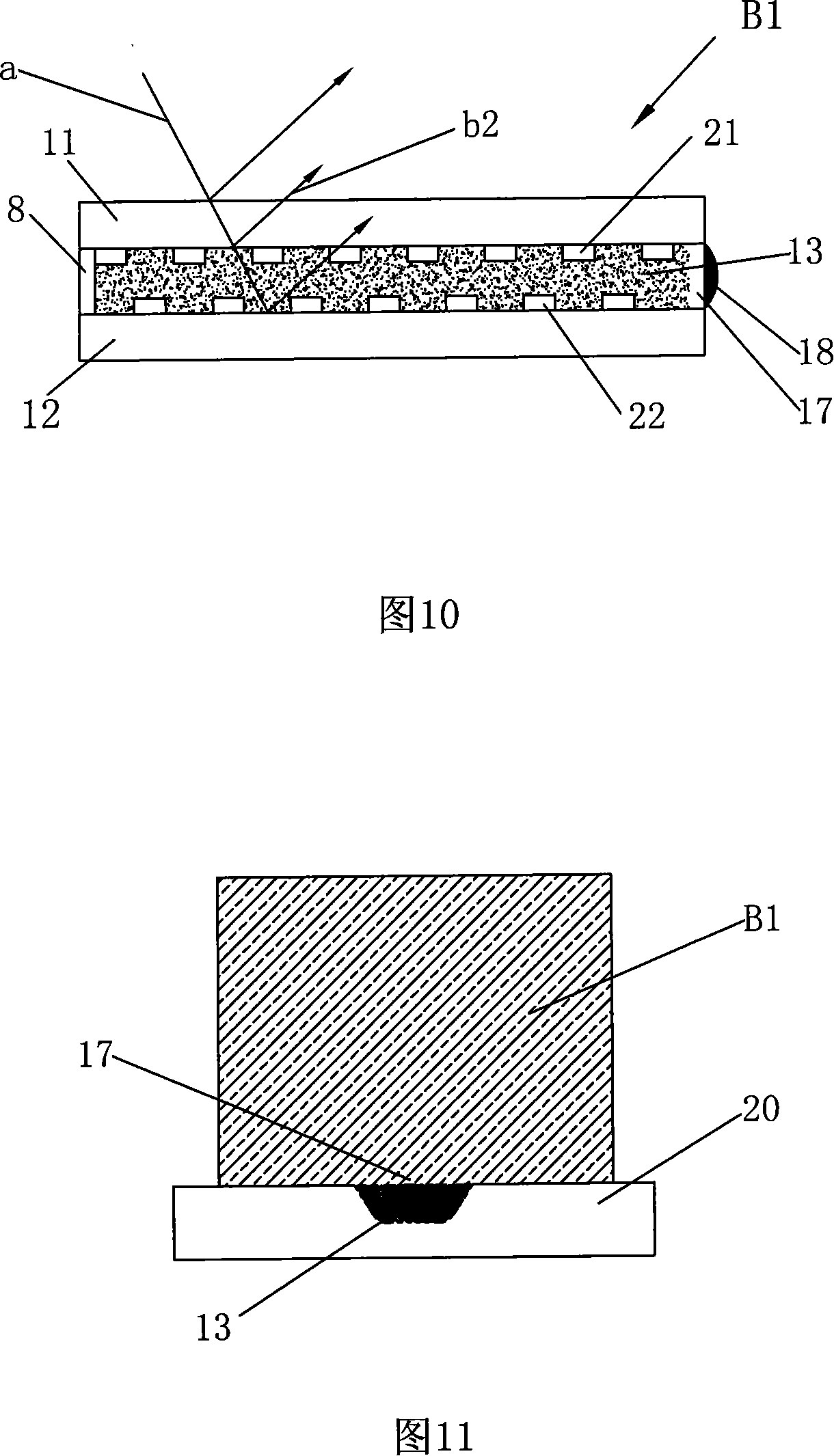

[0038] Embodiment 1 of the present invention is shown in Figures 10 to 12. A capacitive touch screen B1 with a double-layer substrate structure includes an upper substrate 11, a lower substrate 12 and a sensing block. The insulating liquid 13 used to control the distance between the two substrates is filled in the gap, which overcomes the uneven distance between the two substrates, thereby effectively avoiding the appearance of Newton's rings. The insulating liquid 13 is liquid crystal, and the capacitive touch screen B1 adopts glass The material of the substrate and the sensing block is indium oxide-tin (ITO). Since the refractive index of glass is about 1.52, the refractive index of indium oxide-tin (ITO) conductive film is about 1.8, the refractive index of liquid crystal is about 1.5, and the refractive index of air is 1, between liquid crystal and glass and indium oxide- On the interface of the tin (ITO) conductive film, the difference in refractive index between the two ...

Embodiment 2

[0049] Embodiment 2 of the present invention is shown in Figure 13, differs from the previous embodiment in that the capacitive touch screen B2 of the double-layer substrate structure is also provided with spacers 16 between the upper substrate 11 and the lower substrate 12, thereby To further ensure that the distance between the two substrates is uniform, the dots 16 can be sprayed with powder or printed by silk screen.

Embodiment 3

[0051] Embodiment 3 of the present invention is shown in Figure 14, differs from Embodiment 1 in that an insulating liquid 13 is poured between the upper and lower substrates of the capacitive touch screen B3 with a double-layer substrate structure, and the dielectric constant of the insulating liquid 13 is greater than 1. Due to the different dielectric constants of different insulating liquids, the sensitivity of the touch screen may also be different. Therefore, in order to achieve the purpose of adjusting the sensitivity of the touch screen, it can be realized by selecting insulating liquids with different dielectric constants. Generally, the dielectric constant of the selected insulating liquid is greater than 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com