Work station regulation means of direct regulating outside cavity laser and adjusting apparatus

A technology for adjusting devices and adjusting methods, which is applied to devices for controlling output parameters of lasers, lasers, semiconductor lasers, etc., can solve problems such as the inability to ensure direct adjustment of external cavity lasers, and achieve the effect of ensuring transmission performance and avoiding deviations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

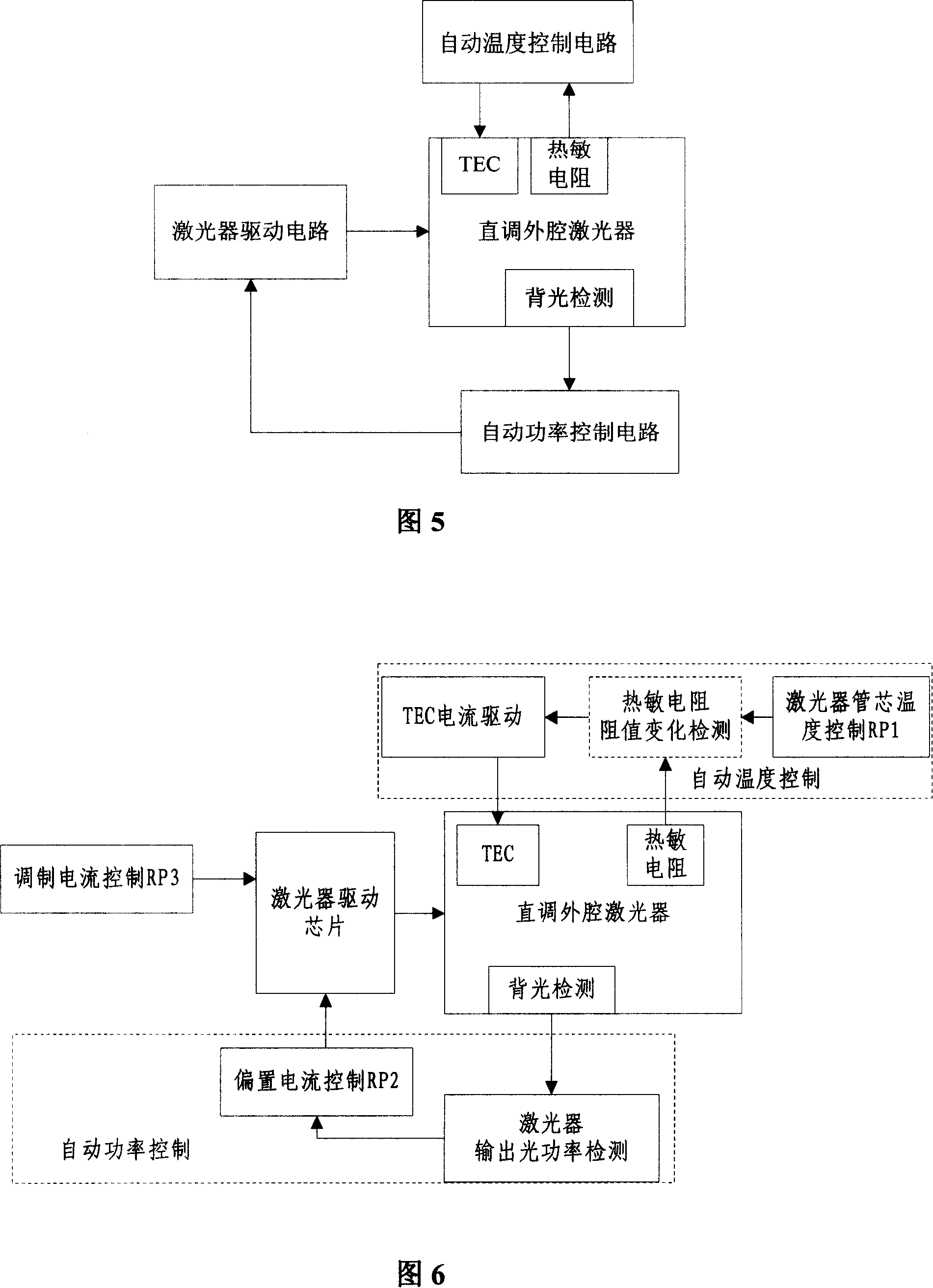

[0042] Please refer to FIG. 6, which is a hardware structure block diagram of Embodiment 1 of the working point adjustment device of the direct-adjusted external cavity laser of the present invention. As shown in the figure: it mainly includes direct-tuning external cavity laser, automatic temperature control loop, automatic power control loop and extinction ratio control circuit. among them:

[0043] The direct-tuning external cavity laser includes a thermistor, TEC (thermoelectric cooler) and backlight detection part in addition to the laser.

[0044] The automatic temperature control circuit: consists of the thermistor resistance value detection circuit, TEC current drive circuit, laser die temperature control circuit (including potentiometer RP1), etc., and forms negative feedback with the thermistor and TEC inside the laser Loop.

[0045] The automatic power control circuit is composed of a laser output optical power detection circuit, a bias current control circuit (includin...

Embodiment 2

[0055] Please refer to FIG. 7 again, which is a hardware structural block diagram of Embodiment 2 of the operating point adjustment device of the direct-adjusted external cavity laser of the present invention. As shown in the figure: it mainly includes direct-tuning external cavity laser, automatic temperature control loop, automatic power control loop and extinction ratio control circuit. among them:

[0056] The direct-tuning external cavity laser includes the thermistor, TEC (thermoelectric cooler) and backlight detection part in addition to the laser.

[0057] Automatic temperature control circuit: It is composed of thermistor resistance detection circuit, TEC current drive circuit, laser die temperature control circuit (including potentiometer RA3), etc., and forms a negative feedback loop with the thermistor and TEC inside the laser road.

[0058] Automatic power control circuit: It is composed of laser output optical power detection circuit, bias current control circuit (in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com