Method for producing adsorbing filter gauze mask

A technology of adsorption, filtration and production methods, applied in the field of masks, can solve problems such as inability to protect human health, achieve good dust blocking effect and ensure human health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with embodiment, the present invention will be further described,

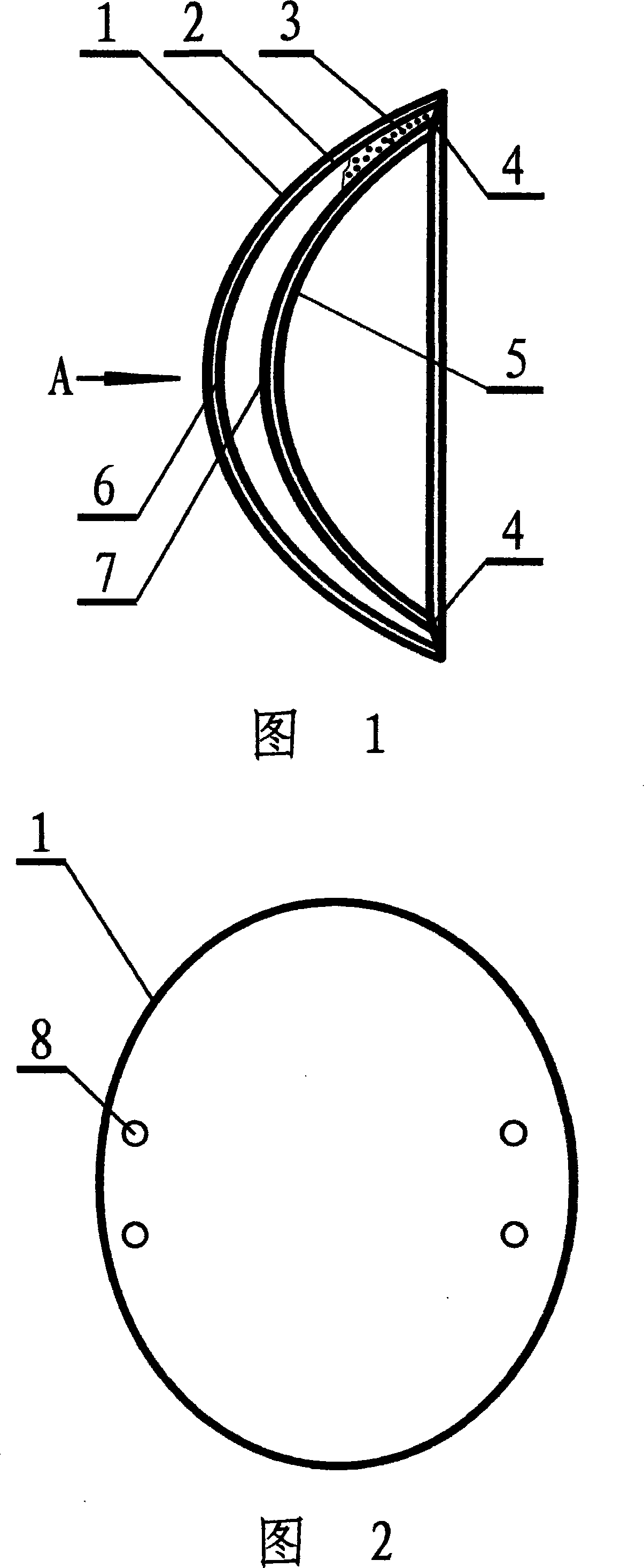

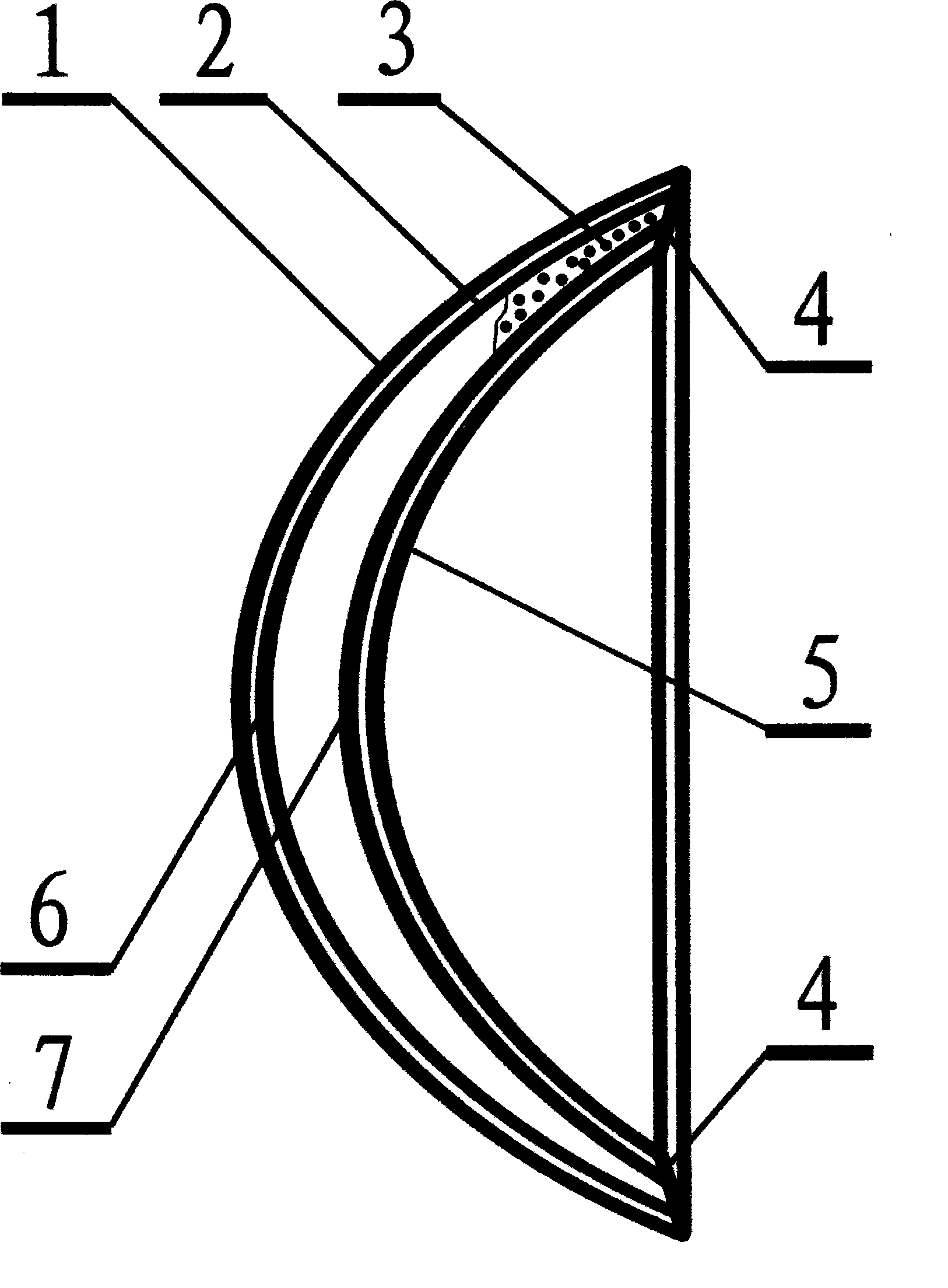

[0025] The production method of the adsorption filter mask is: select the degreasing gauze with good air permeability of one deck on the left side of the natural mineral adsorption filter mask (2), and design it as an outer layer fabric ( 1), use two layers of sterilized medical gauze with good air permeability on the right side of the natural mineral adsorption filter mask (2), and design it as the inner lining (5) according to the shape of the natural mineral adsorption filter mask groove (7). The natural mineral adsorption filter mask (2) is sewn between the outer layer fabric (1) and the inner layer lining (5), and the mask inner layer lining (5) contacts the human body face (4) to the groove cavity (7) ) incline at 6 degrees to ensure the tight contact between the mask and the face. At the positions of the four through holes on the front of the natural mineral adsorption filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com