Sanitary liquid electrical heating tank

A technology of electric heating and electric heater, which is applied in the field of sanitary liquid heating, can solve the problems of reduced heat transfer efficiency, difficulty in cleaning, and rise in operating temperature of electric heating tubes, and achieves low manufacturing cost, simple assembly process, and prevention of dry burning without water Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

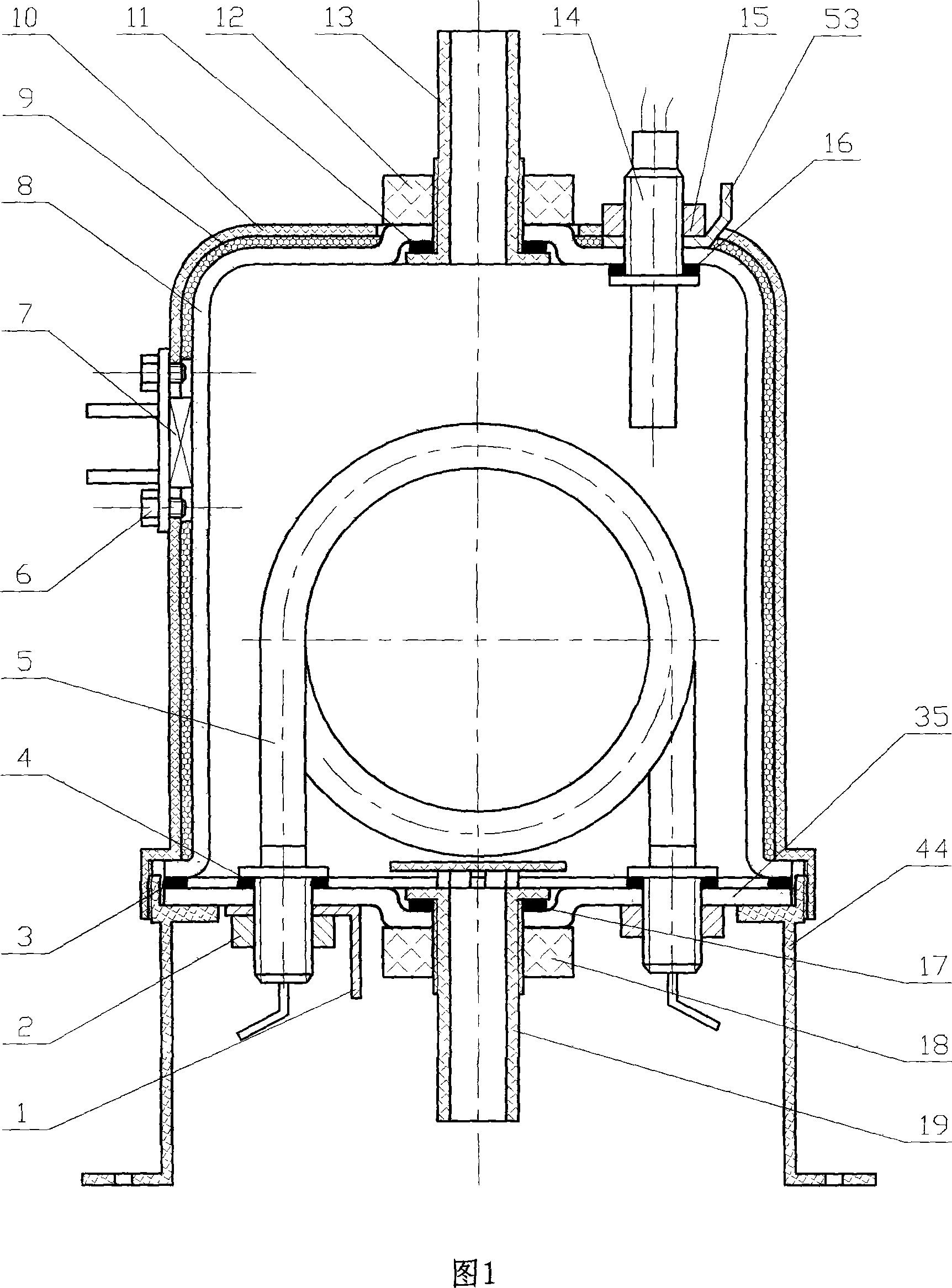

Embodiment 1

[0045] Embodiment one: in conjunction with Fig. 1 and shown in Fig. 2, the tank body of hot pot adopts purple sand pottery material to make, and tank body comprises upper tank body (8) and lower bottom (35) two parts, in upper tank body (8) and The joint of the lower bottom (35) is provided with a sealing ring (3), and the top of the upper tank body (8) is provided with an opening for installing a water outlet exhaust pipe (13) and a temperature measuring probe (14), which are close to the upper tank body The side wall of (8) is provided with manual reset thermostat (7), and bottom (35) is provided with the opening that can assemble electric heating tube (5) and water inlet and drain pipe (19); The outside of described tank body is provided with The shell, the shell includes two parts, the upper shell (10) and the lower shell (44), the upper shell (10) and the lower shell (44) are threadedly connected, the bottom of the upper shell (10) is provided with internal threads, and th...

Embodiment 2

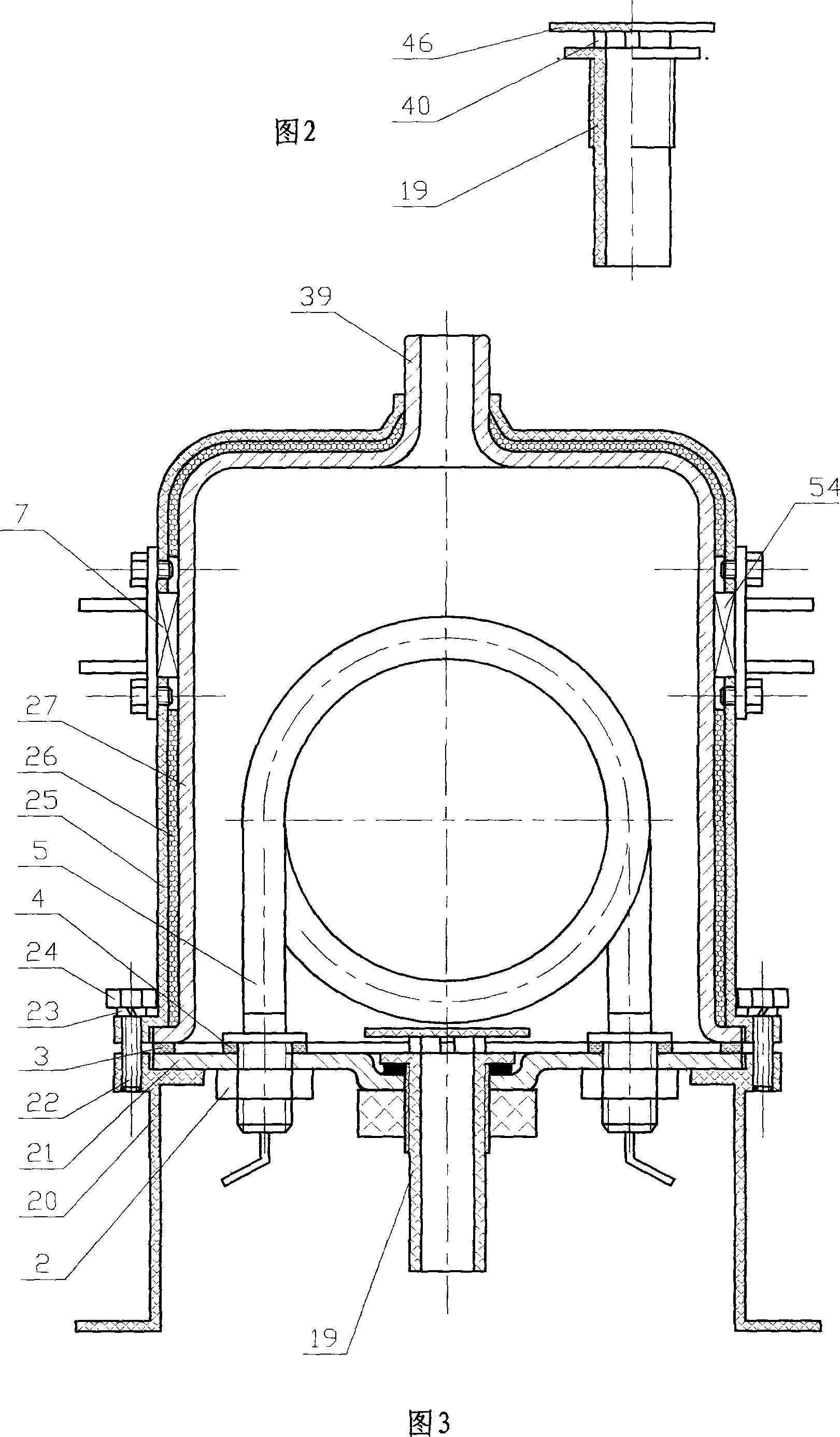

[0046] Embodiment two: in conjunction with shown in Fig. 3, the tank body of heat tank adopts heat-resistant glass to make, and tank body comprises upper tank body (27) and lower bottom (21) two parts, in upper tank body (27) and lower bottom ( 21) is provided with a sealing ring (3) at the joint, the top of the upper tank (27) is provided with a water outlet exhaust pipe (39), and the side wall of the upper tank (27) is provided with a manual reset thermostat ( 7) and an automatic reset thermostat (54), the lower bottom (21) is provided with an opening that can be assembled with a water inlet and drain pipe (19) and an electric heating tube (5); the outside of the tank body is provided with a shell, and the shell includes The upper shell (25) and the lower shell (20) are two parts, the upper shell (25) and the lower shell (20) are fixedly connected by screws (24) and washers (23), the upper shell (25) and the lower shell (20) The connecting part is provided with screw holes, ...

Embodiment 3

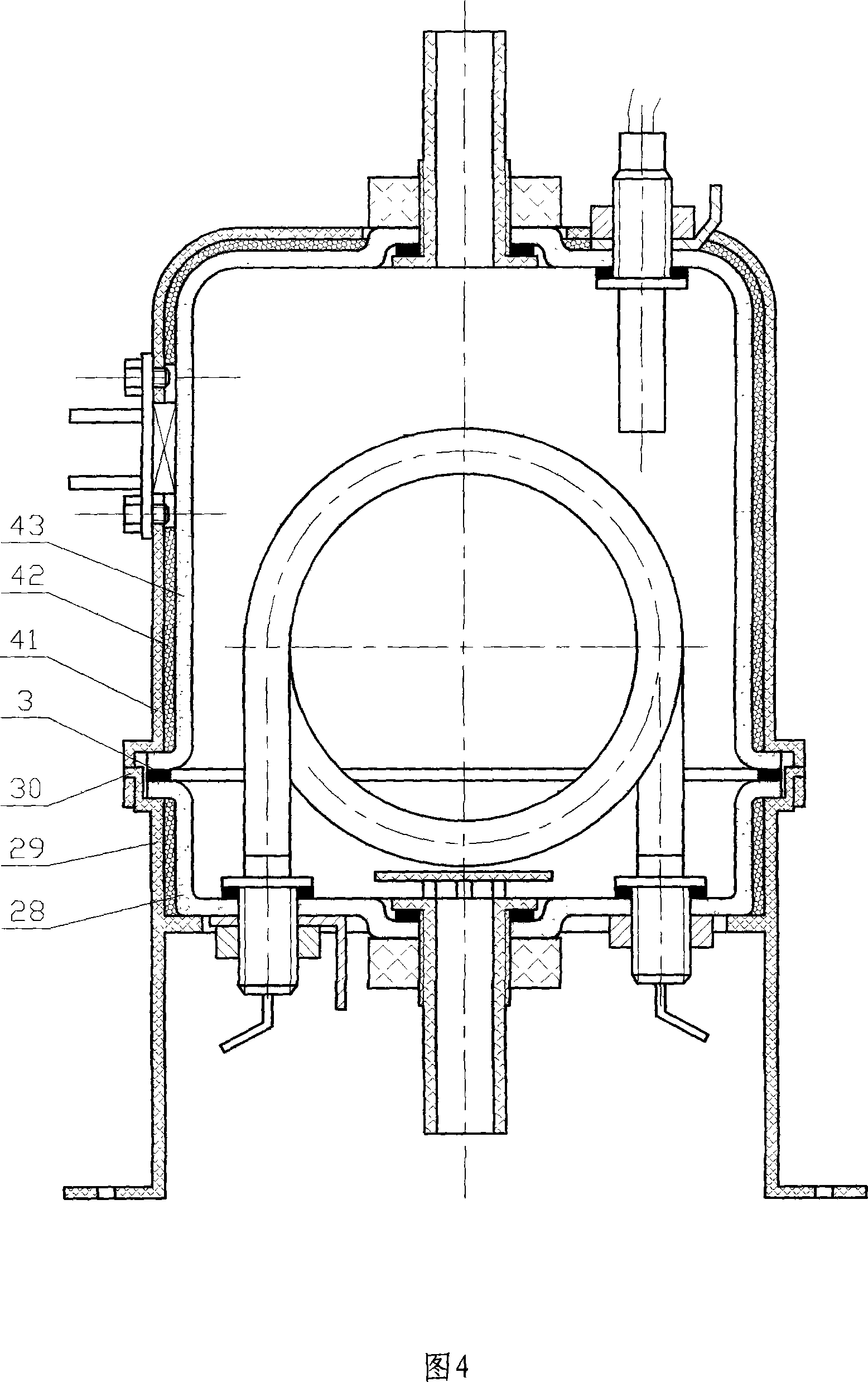

[0047] Embodiment three: in conjunction with shown in Fig. 4, the tank body of hot pot adopts porcelain material to make, and tank body comprises upper tank body (43) and lower tank body (28) two parts, in upper tank body (43) and lower tank body The junction of (28) is provided with sealing ring (3); The outside of described tank body is provided with shell, and shell comprises upper shell (41) and lower shell (29) two parts, upper shell (41) and lower shell ( 29) It is connected by buckle, the lower part of the upper shell (41) is provided with a bayonet, the upper part of the lower shell (29) is provided with a locking tooth (30), and the locking tooth (30) of the lower shell (29) is snapped into the upper shell After the bayonet joint of (41), upper tank body (43) and lower tank body (28) can be connected into one, and sealing ring (3) can be compressed to keep the joint surface in a sealed state; Insulation layer (42) is arranged. Other requirements of this embodiment ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com