Heat pipe structure

A heat pipe and structure technology, used in indirect heat exchangers, lighting and heating equipment, etc., can solve problems such as difficulty in achieving power generation, excessive distance between magnet rings and power output coils, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

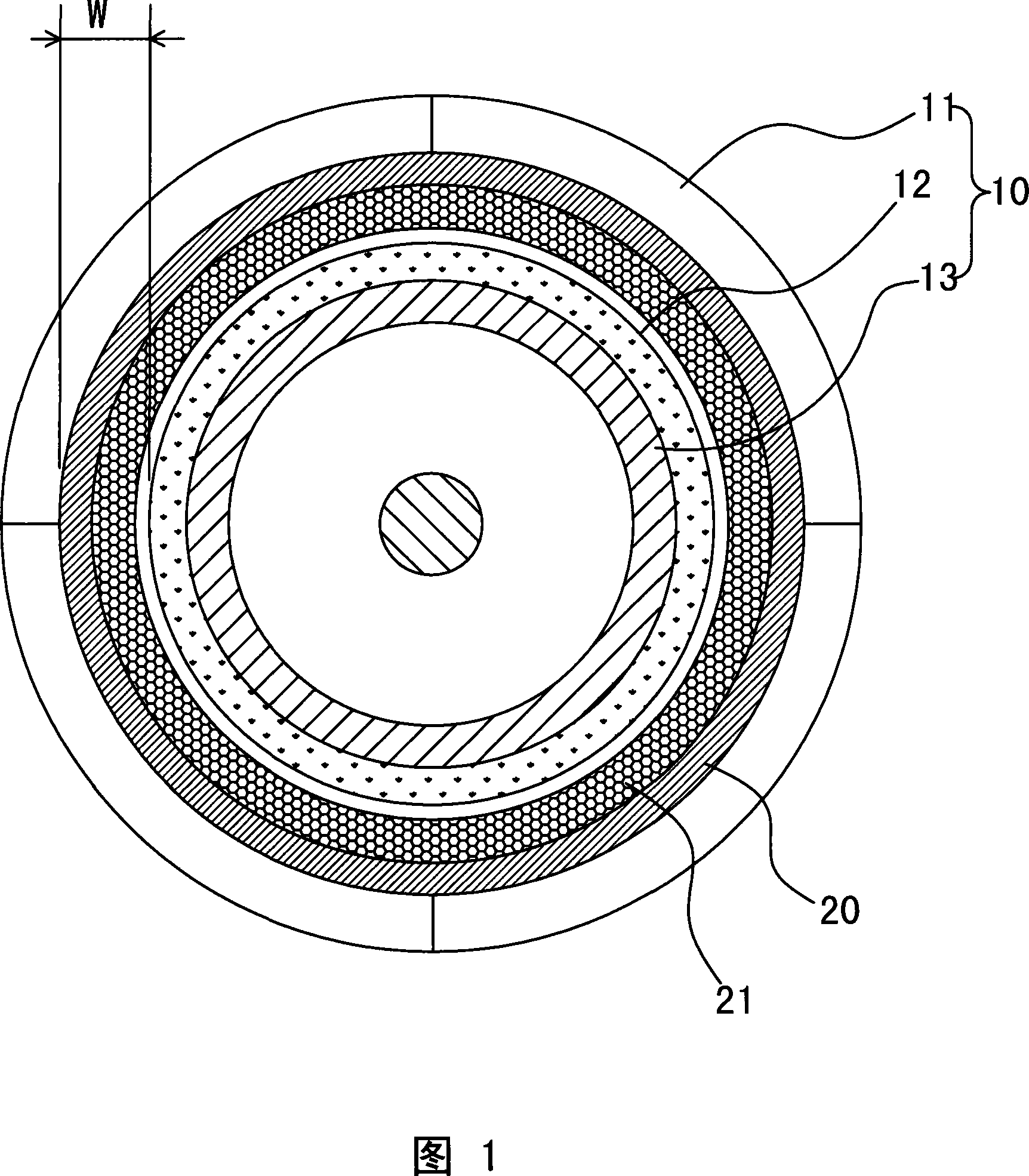

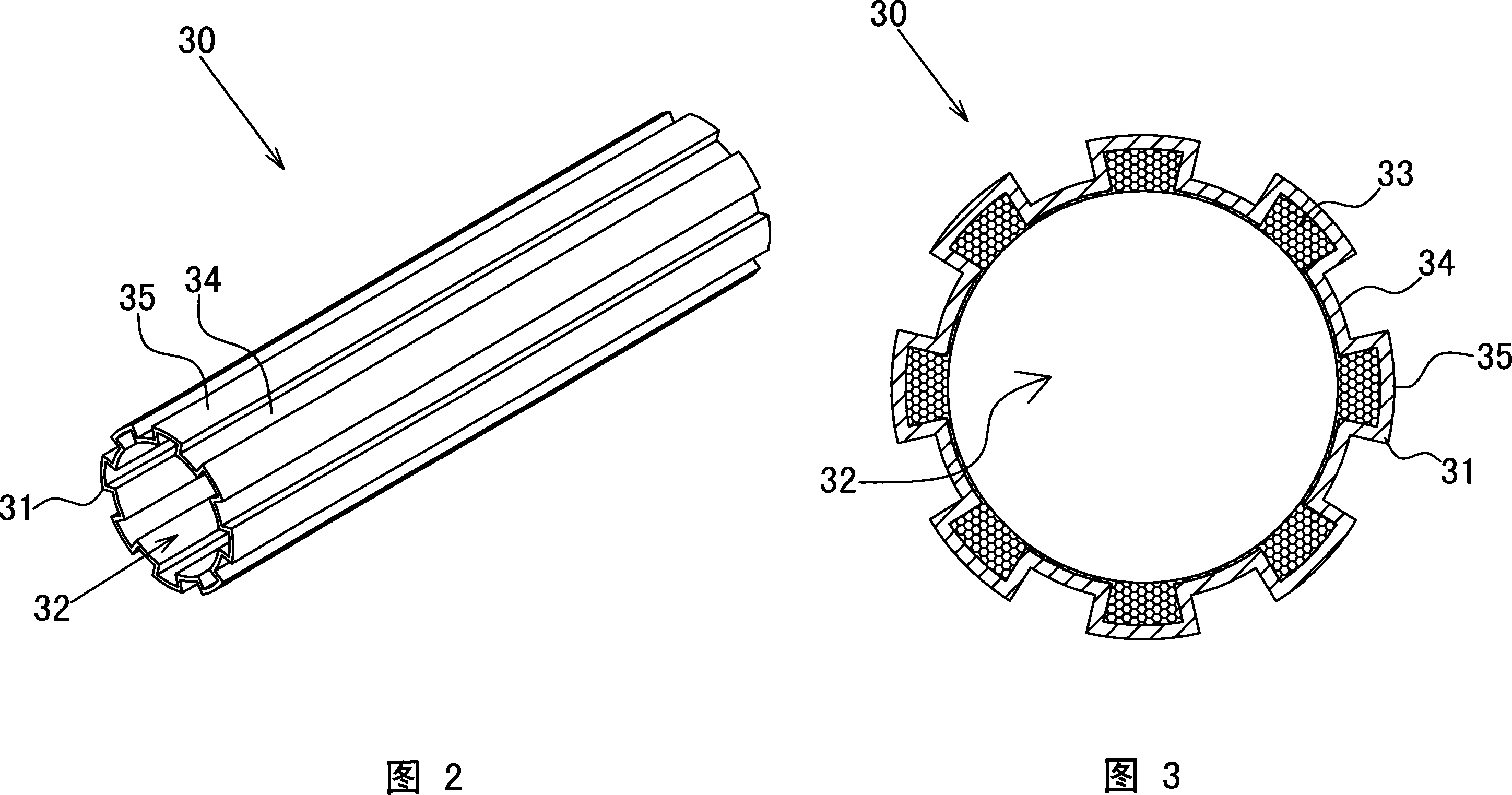

[0028] Please refer to Figures 2 to 3, which are preferred embodiments of the heat pipe structure of the present invention,

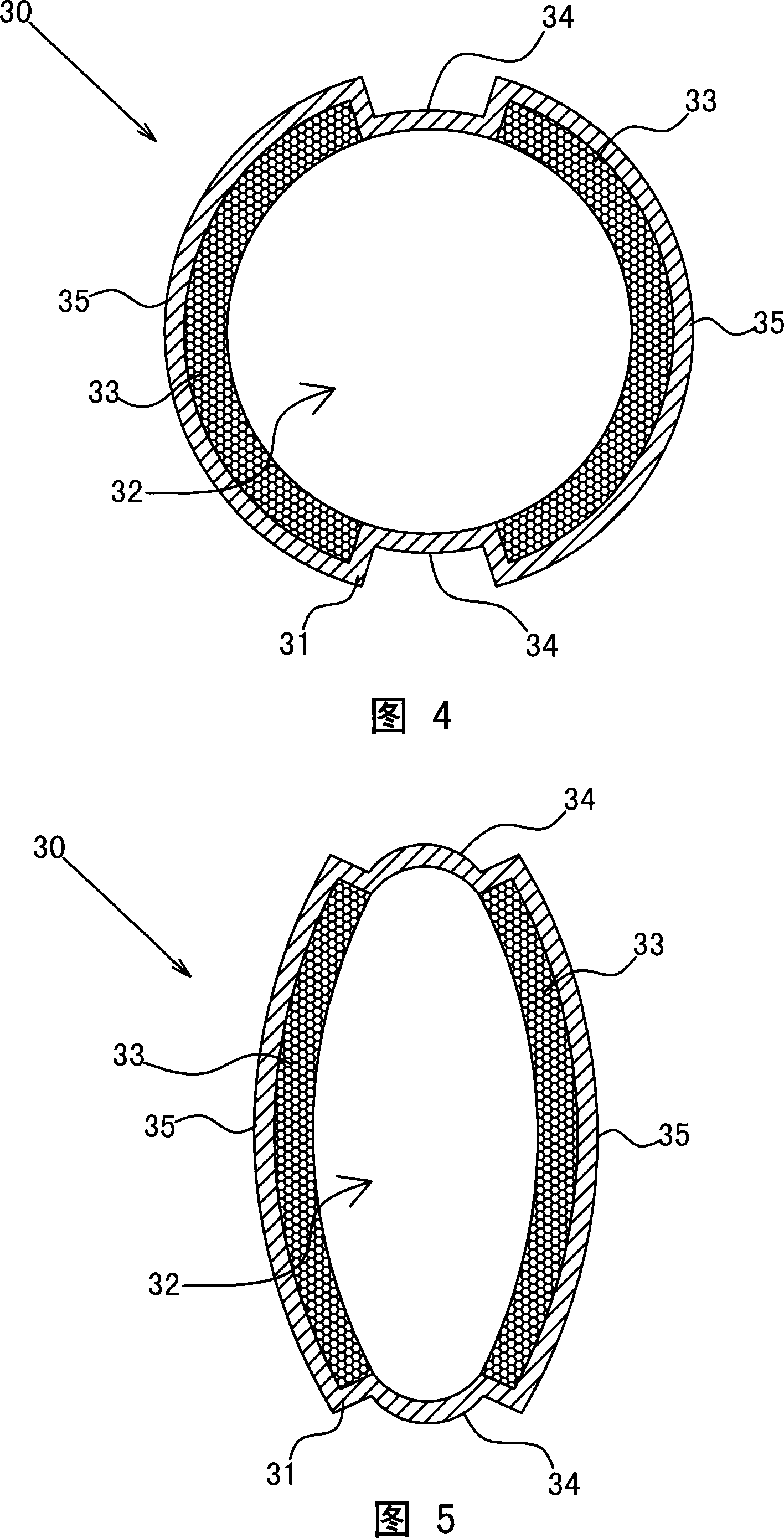

[0029] The heat pipe 30 is a hollow tube body with both ends closed, including a tube wall 31 and a hollow tube groove 32, the inner side of the tube wall 31 is provided with capillary tissue 33, and the inside of the hollow tube groove 32 is in a vacuum state and Filled with working fluid (please refer to the state of the heat pipe shown in FIG. 8 ), the pipe wall 31 of the heat pipe 30 is concave-convex and wrinkled, and a plurality of concave edge portions 34 and flange portions 35 are formed.

[0030] Wherein, as shown in Figure 2, the concave edge portion 34 and the flange portion 35 can be distributed in the structural form of the entire section of the heat pipe 30 wall 31, or the heat pipe 30 as shown in Figure 5, the concave edge portion 34B and the flange portion 35B are structural forms distributed in a local section of the tube wall 31 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com