Chip welding quality checking method

A technology for chip welding and testing methods, which is applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of inaccurate positioning of welding quality problems, long development cycle of test programs, etc., to achieve rapid reuse and improve detection efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

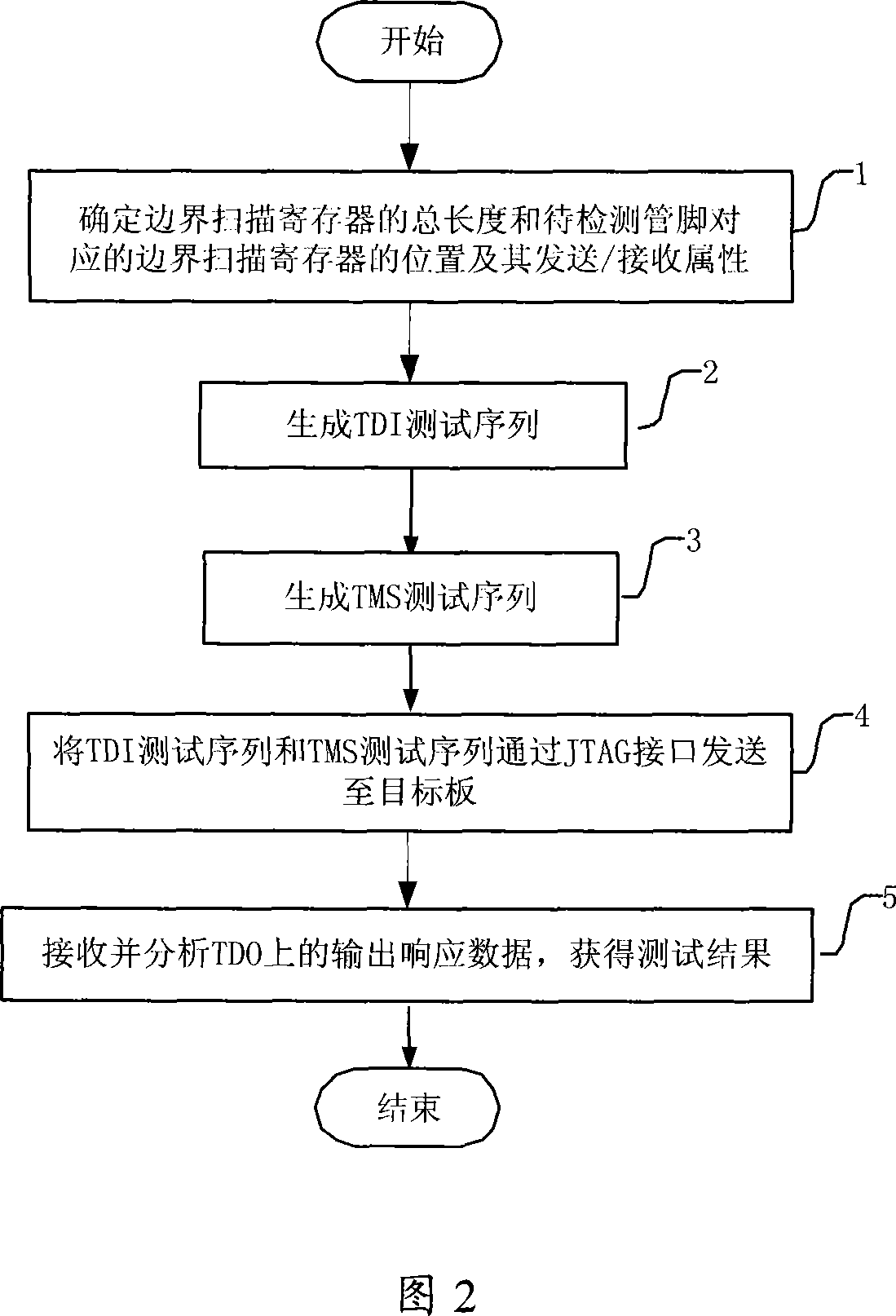

[0023] The key points of the technical scheme of the present invention are: generate a specific test data packet containing a TDI test sequence and a corresponding TMS test sequence according to the position information of the JTAG shift register corresponding to the solder joint to be detected in the PCB board, and test the The data packet is sent to the device to be tested through the JTAG interface, and the welding quality is accurately detected by analyzing the output response of the device to be tested.

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

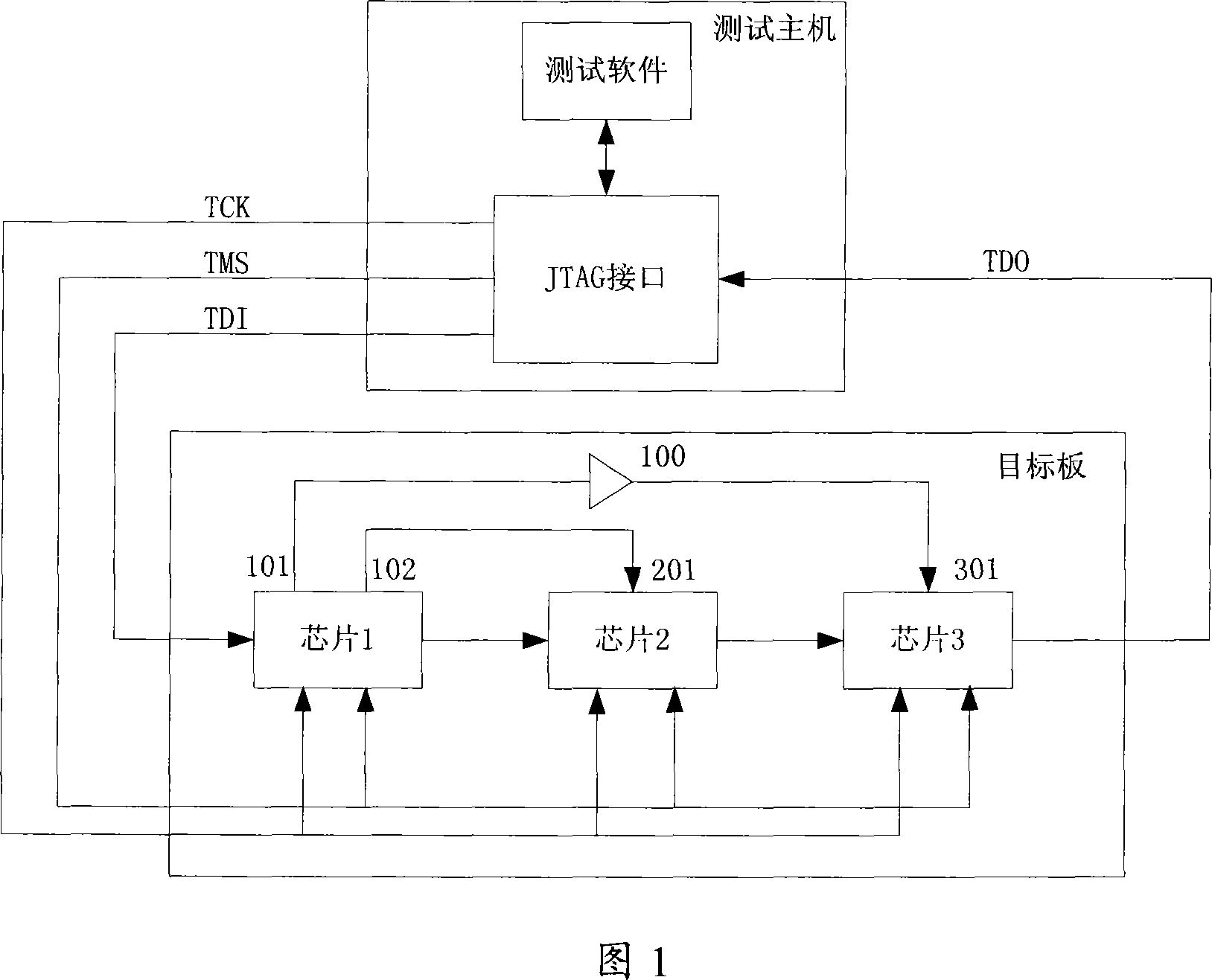

[0025] FIG. 1 is a schematic diagram of the system structure of the detection method for chip soldering quality of the present invention. As shown in Figure 1, the test software is run on the test host, and the test host is connected to the target board (PCB board) to be tested which contains 3 chips with JTAG ports through the JTAG interface. At the same time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com