Power factor correction circuit

A technology of power factor correction and power factor correction, which is applied in the field of power factor correction circuits, can solve problems such as peak high voltage, achieve the effect of reducing costs and meeting the requirements of electrical clearance and creepage distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

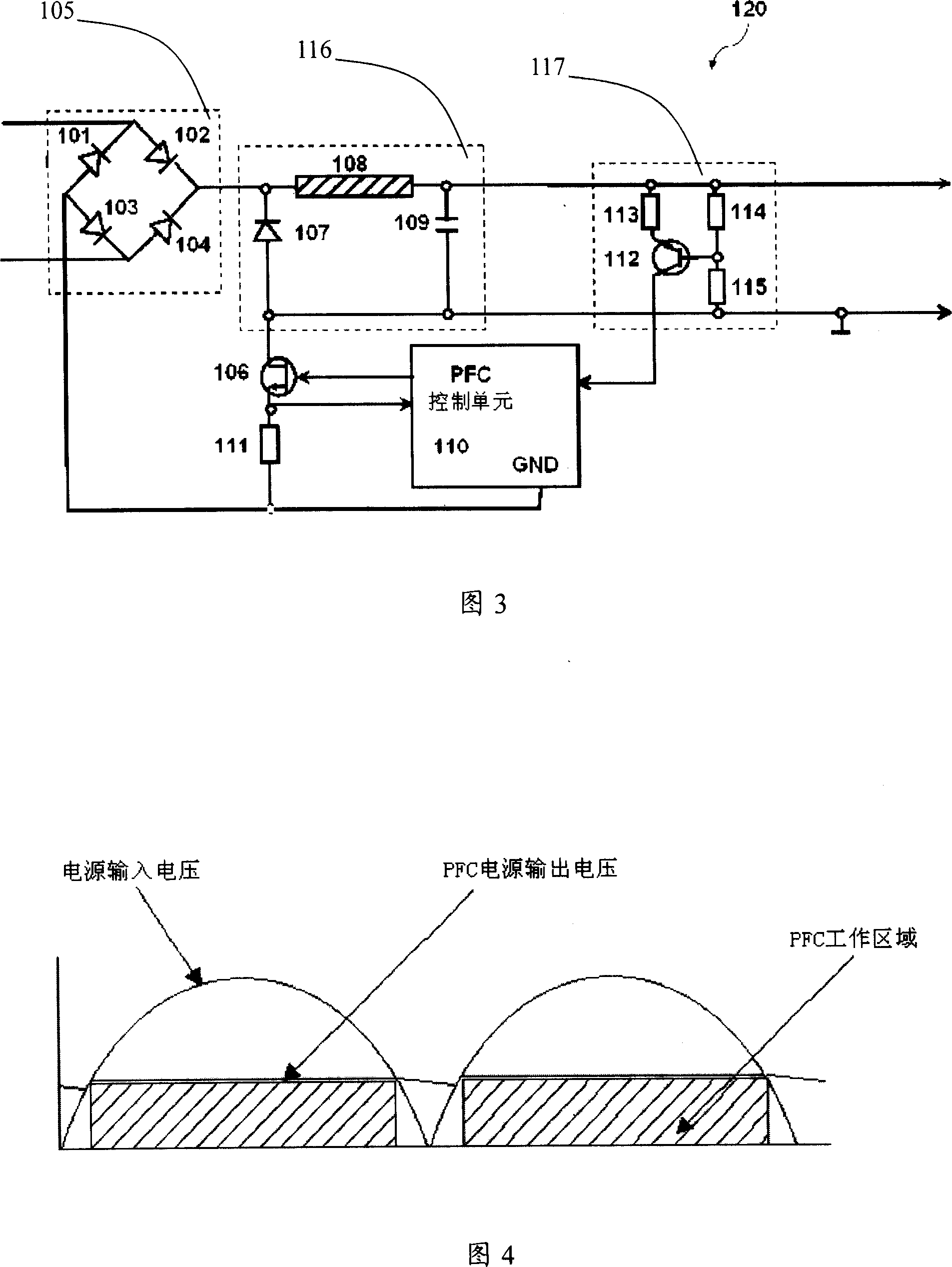

[0012] Please refer to FIG. 3 , which is a circuit diagram of the step-down regulator circuit of the present invention. The circuit includes a power supply (mains) rectifier 105 with four diodes 101, 102, 103, 104, a switch 106, a detection resistor 111, a step-down circuit 107 with a diode 107, an inductor 108, and a capacitor 109, a transistor 112 and three A current source 117 of resistors 113, 114, 115. The switch 106 and the transistor 112 can be bipolar transistors or MOS transistors. In this embodiment, the switch 106 is a MOS transistor, and the transistor 112 is a bipolar transistor.

[0013] In this circuit, one end of the inductor 108 is connected to the cathode of the diode 107 , and the other end is connected to one end of the capacitor 109 . The other end of the capacitor 109 and the anode of the diode 107 are both connected to the drain of the switch 106, the cathode of the diode 107 is also connected to one end of the power rectifier 105, and the ground pin of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com