Passive combined multi-purpose thimble device

A multi-purpose, thimble technology, used in electrical components, electrical components and other directions, can solve the problems of unstable work, insufficient support density, and the inability of the placement machine to meet the requirements, and achieve the effect of strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

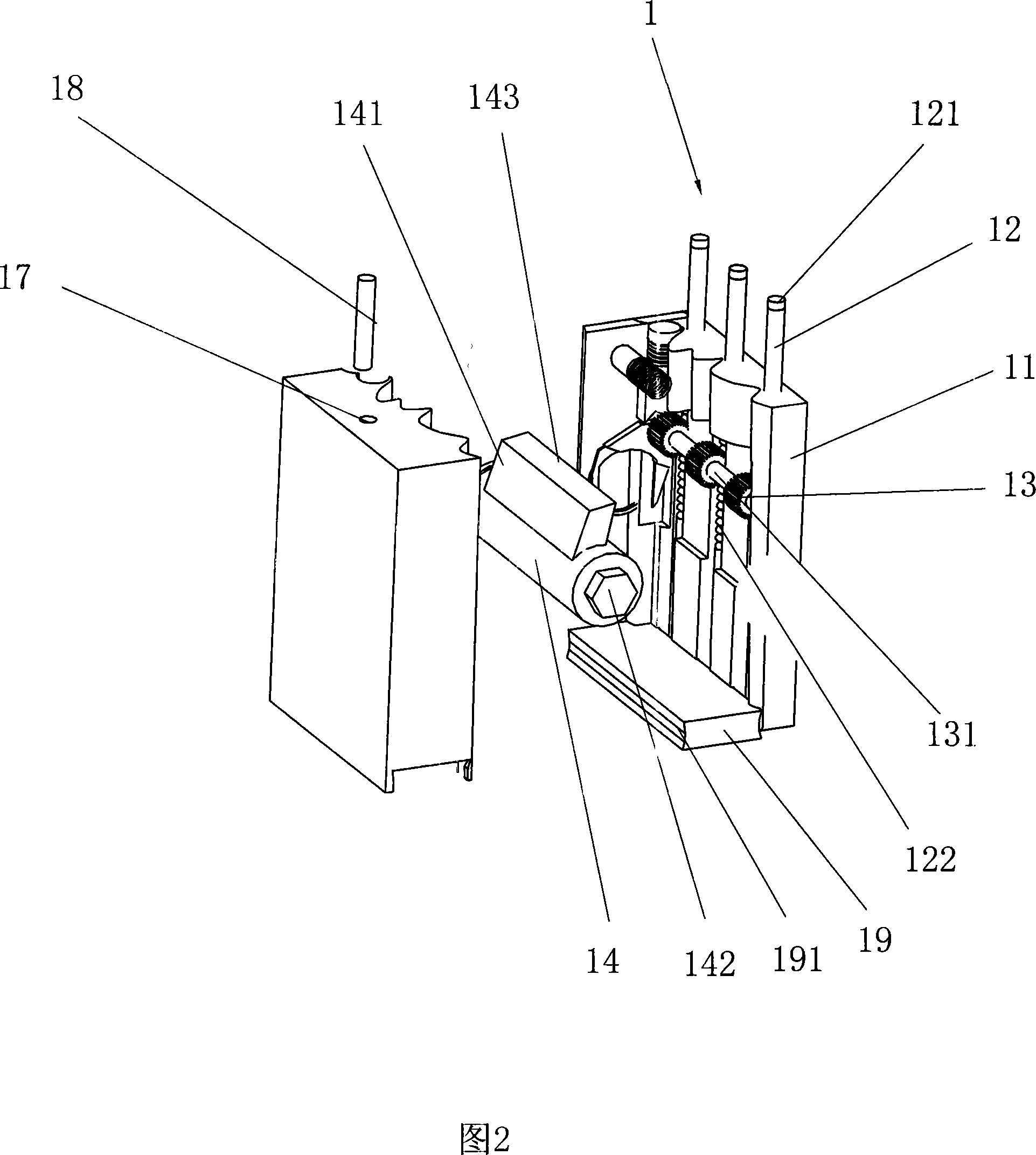

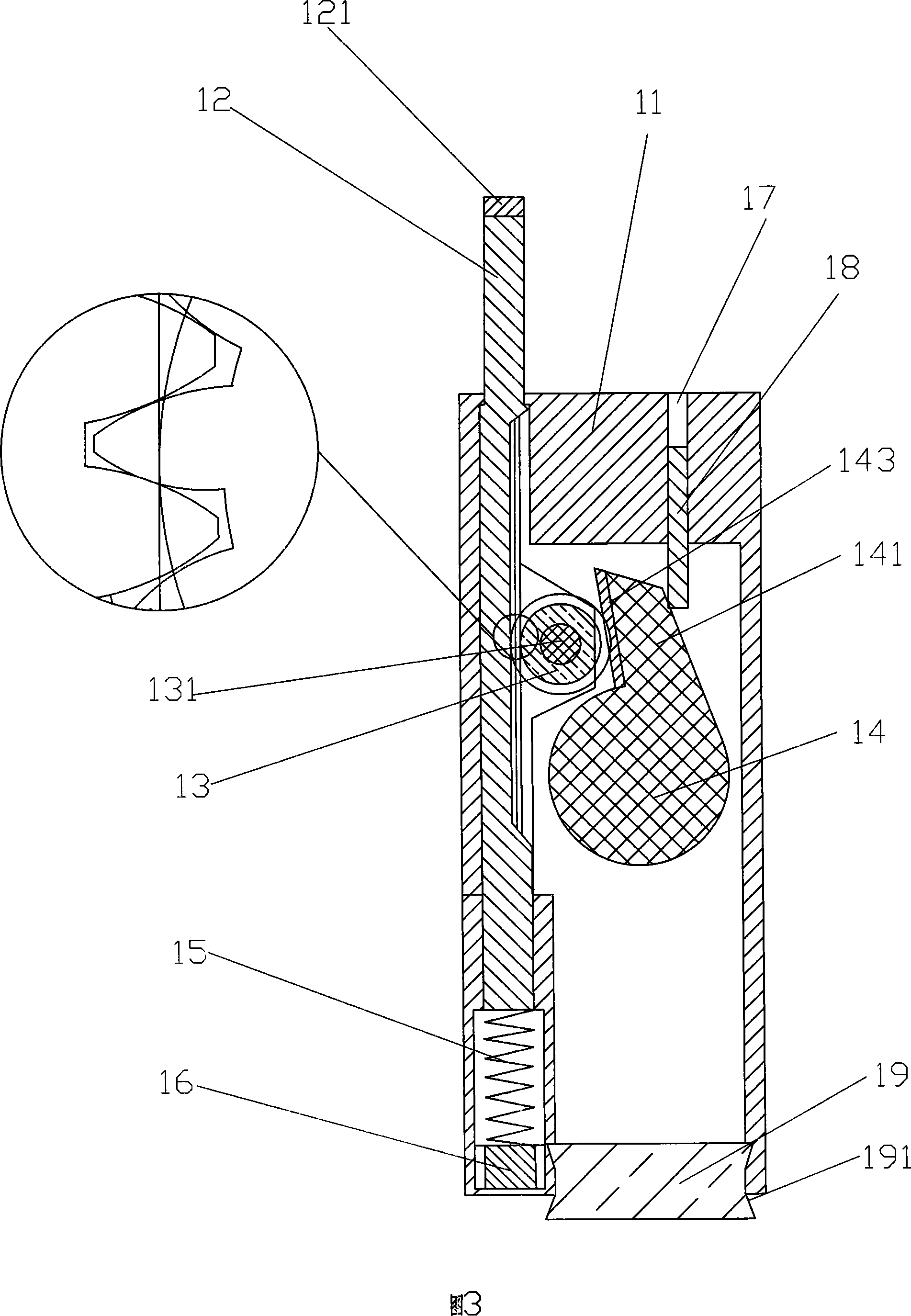

illustration:

[0020] 1. Ejector unit;

[0021] 11. Main frame; 12. Ejector with rack; 121. Soft layer; 122. Rack; 13. Gear; 131. Gear shaft; 14. Connecting shaft; 141. Brake block; 142. Protrusion; 143, rubber layer; 144, blind hole; 15, elastic member, 16, spring adjustment screw; 17, hole; 18, brake block locking column; 19, base connection block; 191, dovetail groove.

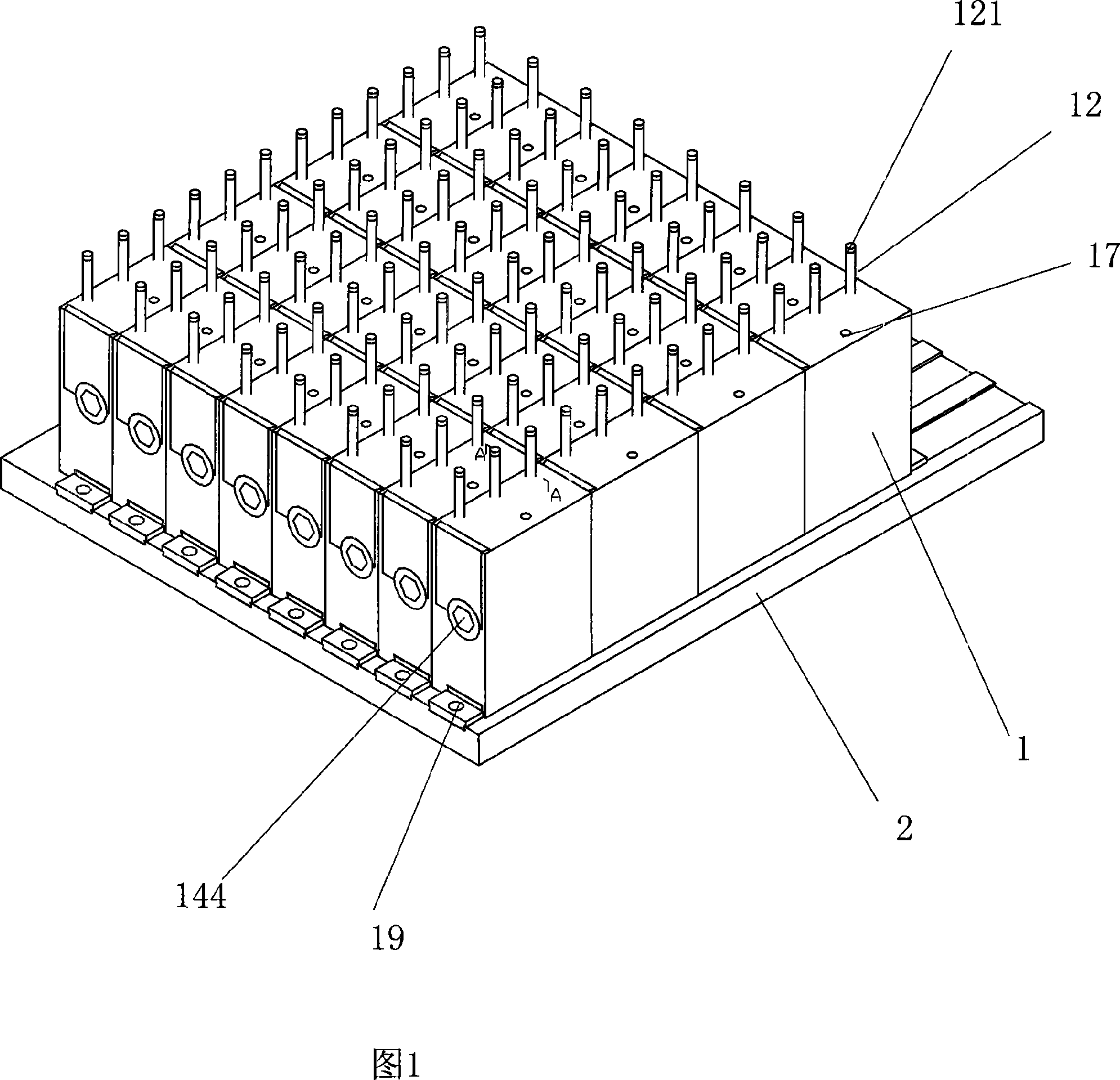

[0022] Please refer to Fig. 1, it is a passive combined multi-purpose thimble device, it has 32 thimble units 1 arranged on the base 2 of a whole board, and the thimble units 1 are detachably arranged on the base through the base connecting block 19 on the base 2.

[0023] Apparently, the aforementioned bases 2 can also be strip-shaped, and one or more thimble units 1 can be arranged on each base 2 , and two or more strip-shaped bases 2 can be assembled into an integral structure.

[0024] Please refer to Figure 2 and Figure 3, Figure 2 is a schematic cross-sectional view of the thimble unit in Figure 1;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com