Rotating stripping head for cable stripping apparatus

A technology for stripping equipment and cables, which is applied in the field of rotary insulator stripping heads, can solve problems such as complex manufacturing processes, and achieve the effects of low production cost, easy production, and easy cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

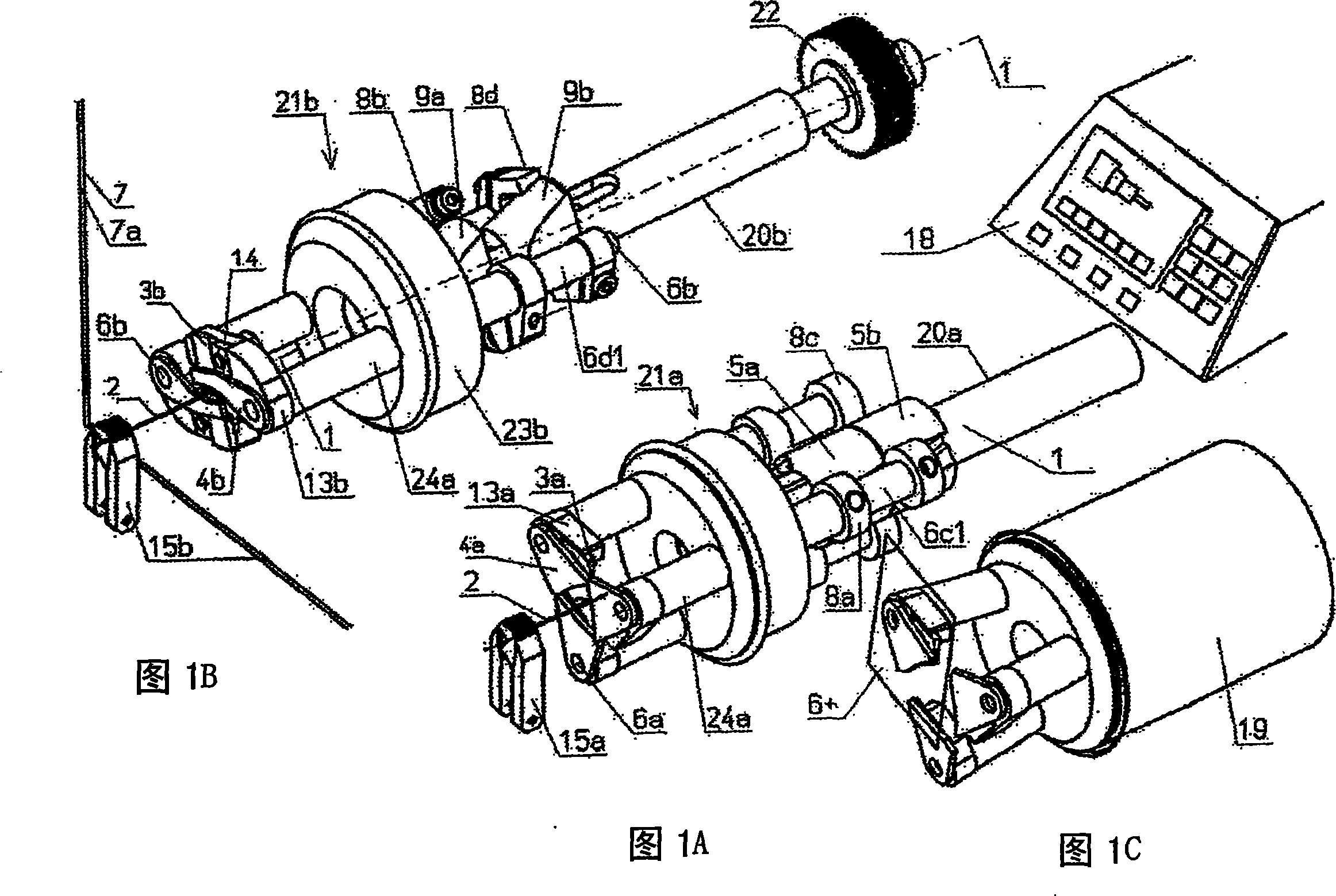

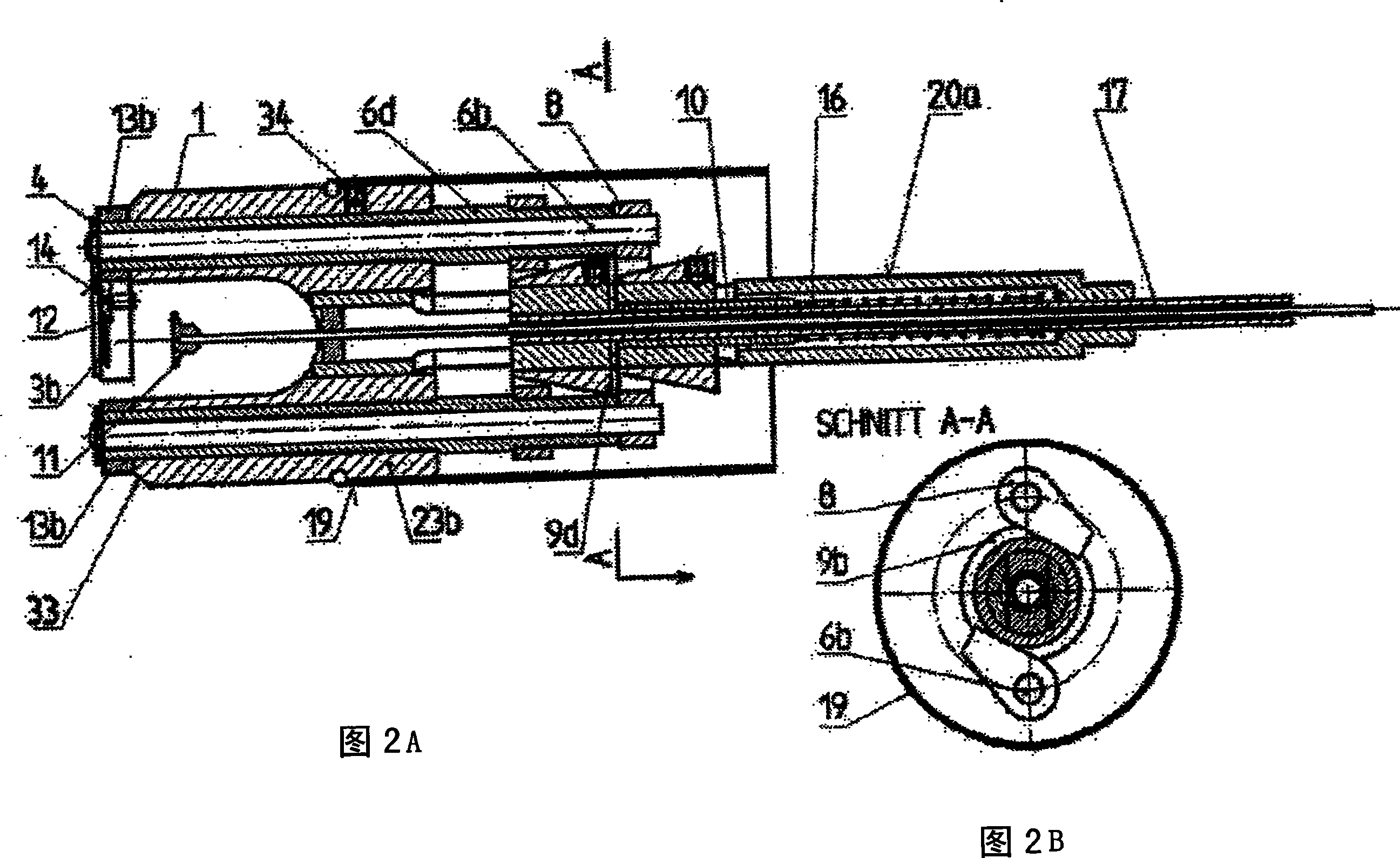

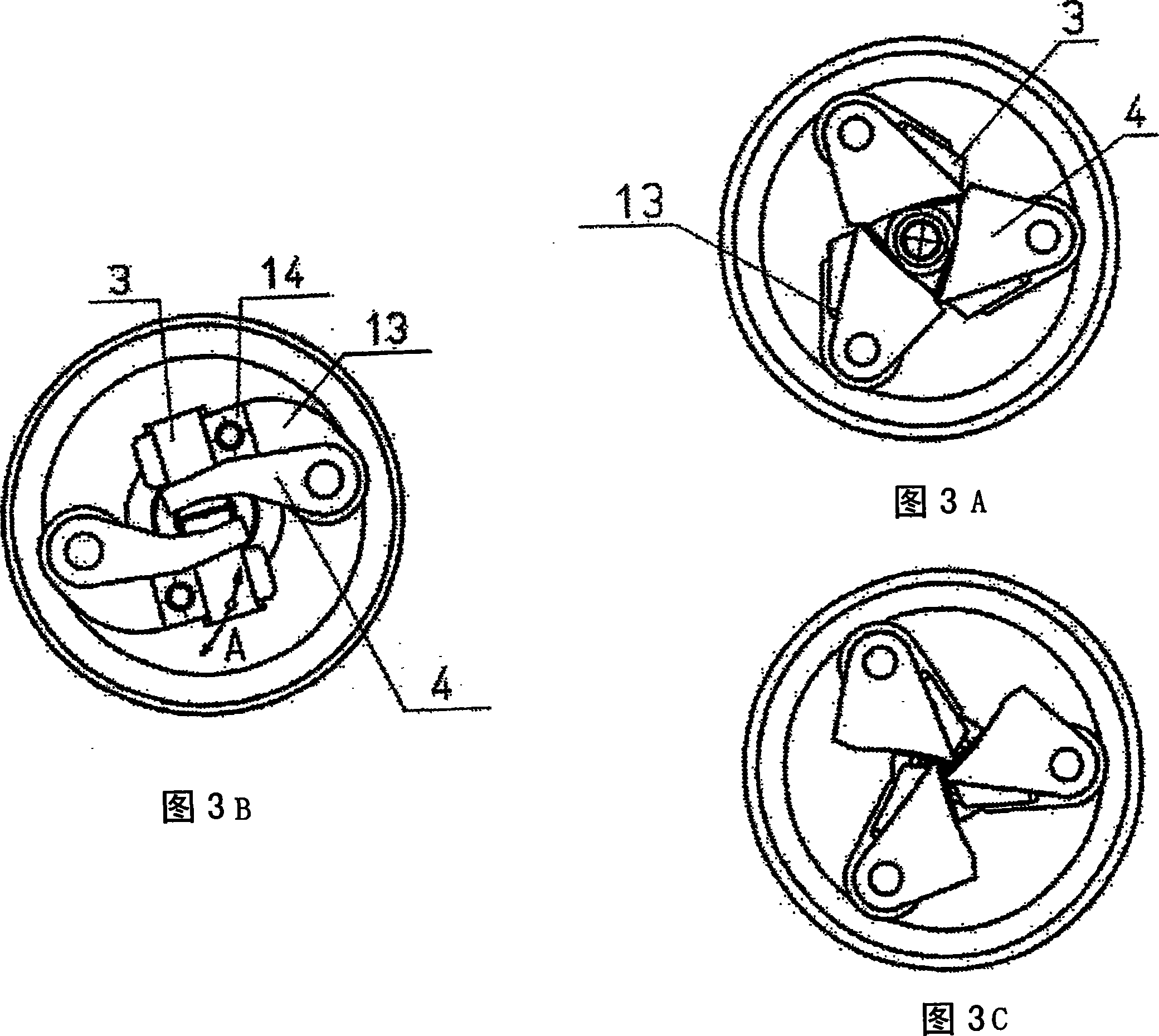

[0058] For a certain function, the different insulation stripping heads according to FIGS. 1 a and 1 b should be considered together.

[0059] For simplicity, they are both shown with their insulation stripping blades 3a, 3b in the normal plane 7 of the main axis 1 (common in the figure). According to an embodiment, the clamping device 15 is displaceable relative to this normal plane 7, so that, as shown in FIG. 7 is pushed into the space behind the insulation stripping blade 3a, and at the same time, in the diagram according to FIG. Pull out from the space behind the insulation stripping blade 3b and back before the normal plane 7, and pieces (not visible in the figure) have been removed. The fragments fall into the space behind the insulation stripping blade 3b, or remain on the conductors of the cable 2 etc. as long as a limited insulation stripping (with a "window") is set.

[0060]Especially in the case of those insulation stripping plants in which the clamping device i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com