Under well explosion-proof strong-magnetic dipole deironing device

An iron remover and strong magnetic technology, applied in the fields of magnetic separation, chemical instruments and methods, solid separation, etc., can solve the problem that the excitation coil of the magnetic core is easy to cause explosion, affect the production process, scratch the belt, etc., and increase the effective area. , The effect of a wide range of applications and prolonged action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

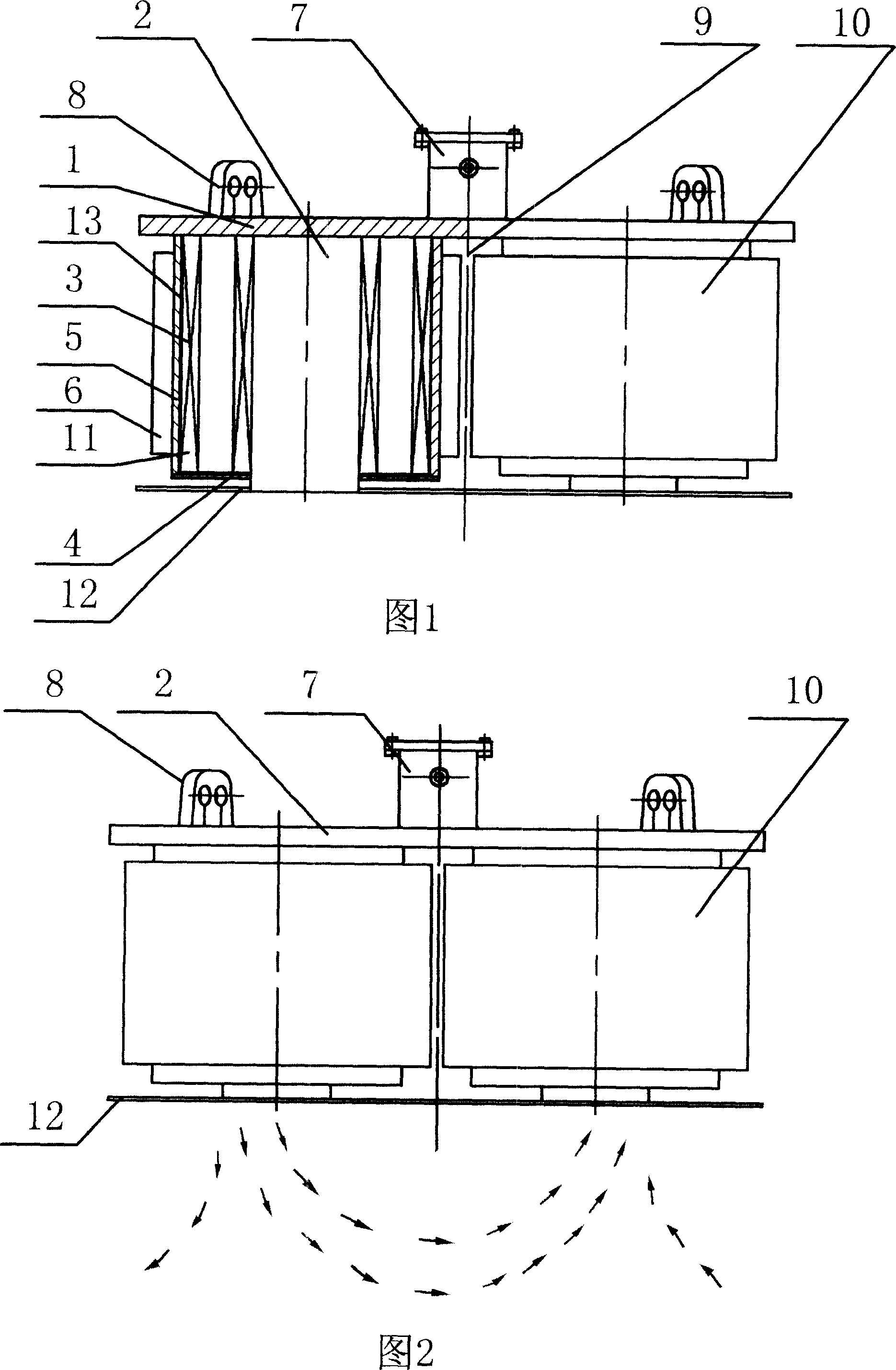

[0008] It can be seen from FIG. 1 and FIG. 2 that the present invention includes a yoke plate 1 , lifting lugs 8 installed on the yoke plate 1 , a junction box 7 and a lower supporting plate 12 . Two electromagnetic cores 10 are arranged side by side between the yoke plate 1 and the lower supporting plate 12 , and a certain distance 9 is left between the two magnetic cores 10 . It can greatly widen the magnetic field action area, and the magnetic field lines are tight. The electromagnetic core 10 includes an iron core 2 welded on the lower end of the yoke plate 1 , an exciting coil 3 and an inner supporting plate 4 . The excitation coil 3 is wound on the outside of the iron core 2 according to the best heat dissipation conditions. An annular sealing cylinder 11 surrounded by an outer sealing layer 5 , a lower inner support plate 4 , an upper yoke plate 1 and an inner iron core 2 is provided outside the excitation coil 3 . The upper and lower ends of the sealing layer 5 are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com