Semiconductor laser device, its manufacturing method and optical pickup head device using the same

A laser device and semiconductor technology, applied in the direction of semiconductor lasers, semiconductor devices, optical recording heads, etc., can solve problems such as difficult heat dissipation of light-emitting elements, damage to the reliability of semiconductor laser devices, and deterioration of light-emitting elements, etc., to achieve miniaturization , prolong life, and prevent deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Preferred embodiments of the present invention will be described in detail below with reference to the drawings.

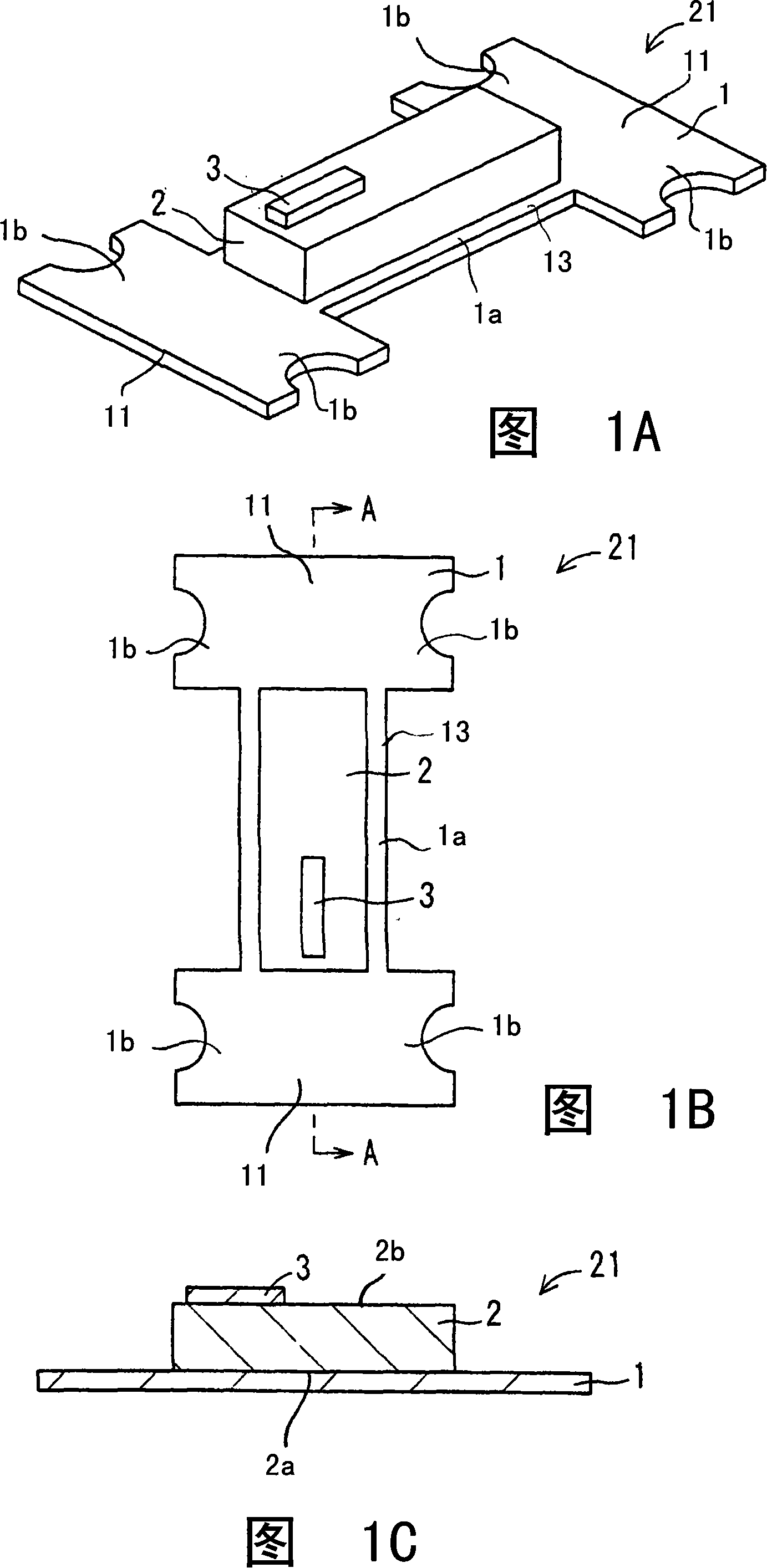

[0059] 1A is a perspective view showing a semiconductor laser device 21 according to a first embodiment of the present invention, FIG. 1B is a plan view, and FIG. 1C is a cross-sectional view taken along line A-A of FIG. 1B . The semiconductor laser device 21 includes a flat plate 1 , a bulk body 2 , and a laser chip 3 . The flat plate 1 is a member for joining with the housing, and includes: a rectangular joining portion 1a joined to the block 2; The exposed part 11. That is, the exposed portion 11 is provided on the flat plate 1 in which a part of one side surface joined to the block body 2 is exposed. The block 2 is formed in a rectangular parallelepiped, and is joined to a surface perpendicular to the thickness direction of the joining portion 1 a of the flat plate 1 . The laser chip 3 is bonded to the surface 2 b of the bulk body 2 opposite to the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com