A processing method of noodle

A processing method and noodle technology, which is applied in the field of noodle processing, can solve the problems of shortening processing time and limitations of cooking methods, and achieve the effects of shortening processing time, achieving continuity, and smooth taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

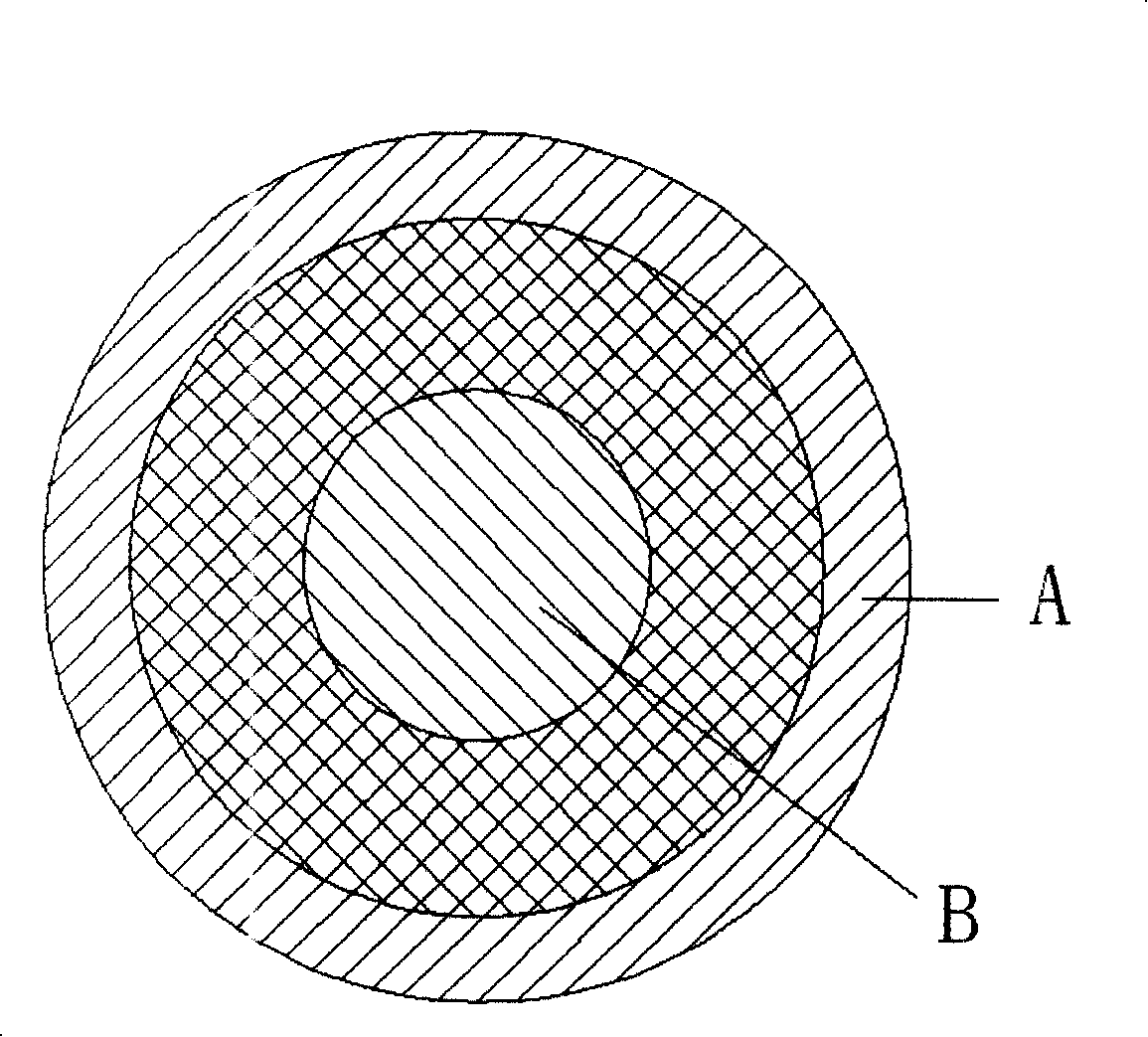

Image

Examples

Embodiment 1

[0018] Embodiment 1: Mix flour and water, and stir until fully; place the dough obtained after stirring in an airtight heat preservation container and suffocate for a certain period of time; then press the dough into sheets and place it in an airtight heat preservation container for a certain period of time , and then stretched into Yangchun noodles to obtain semi-finished Yangchun noodles, put the semi-finished products in the cooking room on the noodle hanging rod for curing, the temperature of the cooking room is controlled at 80-110°C, and the curing heating time is ≤30 minutes, after that, stop heating and Lower the temperature of the cooking room. When the temperature drops to 60-30°C, keep warm for ≤2 hours; then cool down to room temperature and shape according to the desired shape. Finally, dry the semi-finished Yangchun noodles in the sun. The finished product of Yangchun noodles is obtained.

Embodiment 2

[0019] Embodiment 2: Mix flour and water, and stir until fully; the dough obtained after stirring is pressed into sheets and drawn into strips, and then placed in an airtight heat preservation container and stuffed for a certain period of time to obtain semi-finished noodles. Put the obtained semi-finished product on the noodle hanging rod in the cooking room for curing. The temperature of the cooking room is controlled at 110-170°C, and the cooking heating time is ≤20 minutes. After that, stop heating and lower the temperature of the cooking room. When the temperature drops to 50-30°C, Carry out heat preservation, the heat preservation time is less than 4 hours; then, cool to room temperature, and shape according to the required shape, and finally, dry the semi-finished thread surface after shaping to obtain the finished thread surface.

Embodiment 3

[0020] Embodiment 3: Mix flour, water and salt, and stir until fully; Place the dough obtained after stirring in an airtight heat preservation container and suffocate for a certain period of time; Afterwards, press the dough into sheets and place it in an airtight heat preservation container and then suffocate After a certain period of time, it is stretched into thin strips to obtain semi-finished noodles and noodles. The semi-finished products are placed on the noodle hanging rod in the cooking room for curing. The temperature of the cooking room is controlled at 100±5°C, and the curing heating time is ≤15 minutes. After that, stop heating And reduce the temperature of the cooking room. When the temperature drops to 40-30°C, keep warm for ≤ 3 hours; then cool to room temperature and shape according to the required shape. Finally, dry the semi-finished thread and surface after shaping. , to obtain the finished line surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com