White potato delivery pump

A delivery pump and potato technology, applied in the field of starch processing, can solve problems such as easy adhesion of crystallization and sediment, poor metal corrosion resistance, failure to meet design parameters, etc., to achieve strong material passing ability, long practical life, and stable performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

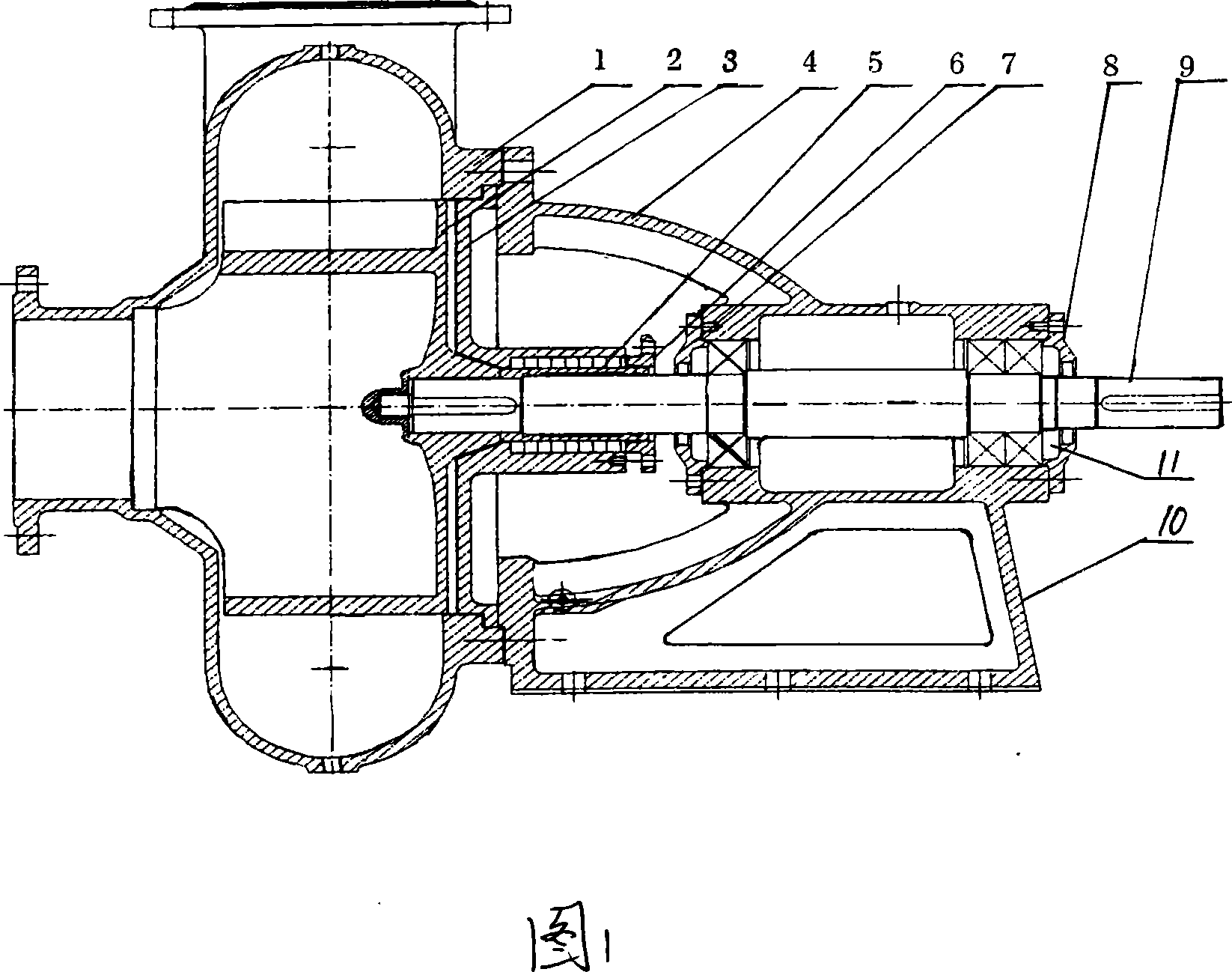

[0011] The present invention comprises a pump body 1, an impeller 2, a pump casing 4, a base 10, a bearing seat is provided at the rear end of the pump casing 4, the pump body 2 is installed on the pump casing 4, a pump cover 3 is installed at the front end of the pump casing 4, and the pump cover 3 and There is a sealing ring at the joint between the pump casings 2 for sealing, and the impeller 2 and the central shaft 9 are fixedly connected, and the central shaft 9 passes through the shaft cylinder on the pump cover 3 and is fixedly installed in the bearing in the bearing seat. There is an interference fit of a shaft sleeve 5 inside the shaft cylinder. There is a seal and a sealing gland 6 between the shaft sleeve 5 and the central shaft 9. The two ends of the bearing seat are fixedly installed with bearings 7. The bearings can be selected from two single-row bearings. The core packing can use flexible wear-resistant rubber skeleton oil seal as packing, and the sealing perfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com