Light sandwich compound material using hollow circular tube backbone

A hollow circular tube, composite material technology, applied in the direction of sheet/board, building elements, etc., can solve the problems of small opening rate of the sandwich layer, inability to achieve multi-functionality, low flexibility, etc., and achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

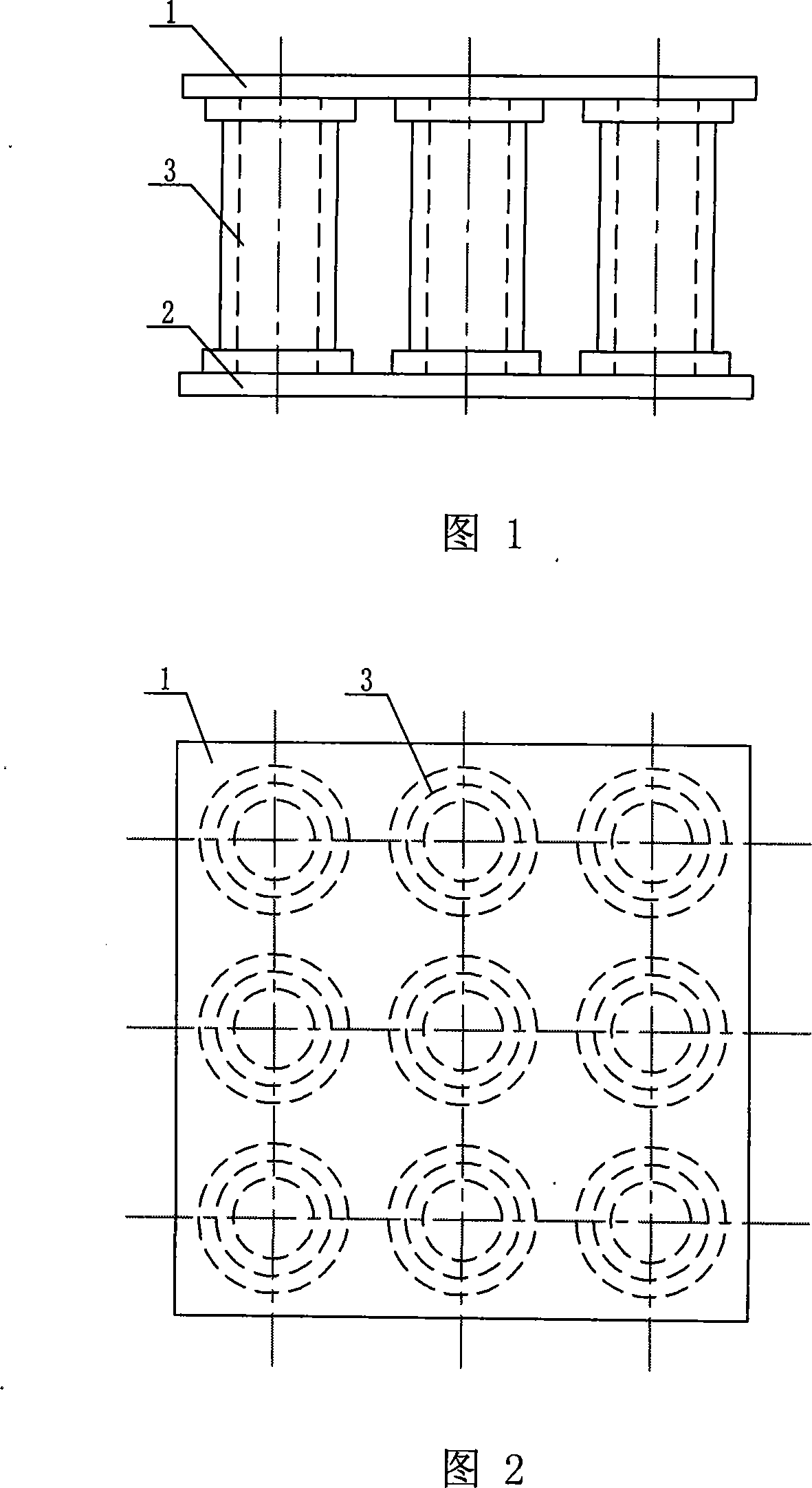

[0007] Specific implementation manner 1: This implementation manner is described in conjunction with FIG. 1 . It is composed of an upper panel 1, a lower panel 2 and a plurality of hollow round tube skeletons 3, and a plurality of hollow round tube skeletons 3 are arranged between the upper panel 1 and the lower panel 2, and the upper end surfaces of the plurality of hollow round tube skeletons 3 and the upper panel The lower surface of 1 is connected, and the lower end surface of a plurality of hollow circular tube skeletons 3 is connected with the upper surface of the lower panel 2 to form.

specific Embodiment approach 2

[0008] Specific embodiment two: the upper end face of a plurality of hollow circular tube skeletons 3 described in this embodiment and the lower surface of the upper panel 1 and the lower end surface of a plurality of hollow circular tube skeletons 3 and the upper surface of the lower panel 2 are bonded by an adhesive film. catch.

[0009] The biggest difference between the present invention and the traditional composite material lies in its multifunctional potential and designability. It adopts a single hollow circular tube core, and the hollow circular tube core adopts different placement forms between the two panels. Different carrying functions can be realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com