Piezoelectric component and method for manufacturing same

A technology of piezoelectric components and piezoelectric vibration elements, applied in the direction of electrical components, impedance networks, etc., to achieve good visual confirmation and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

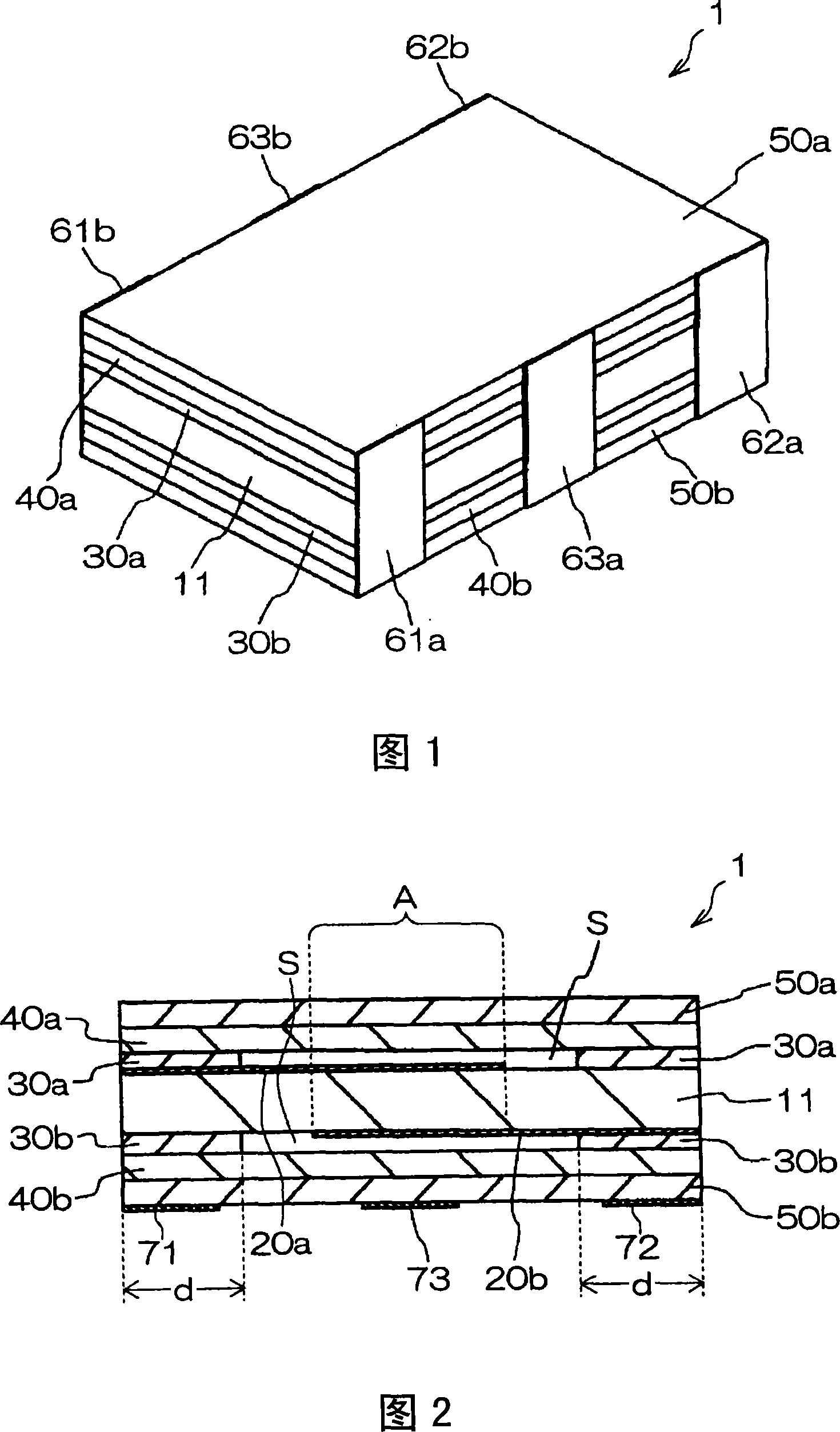

[0047] FIG. 1 is an external perspective view schematically showing a piezoelectric component according to an embodiment of the present invention.

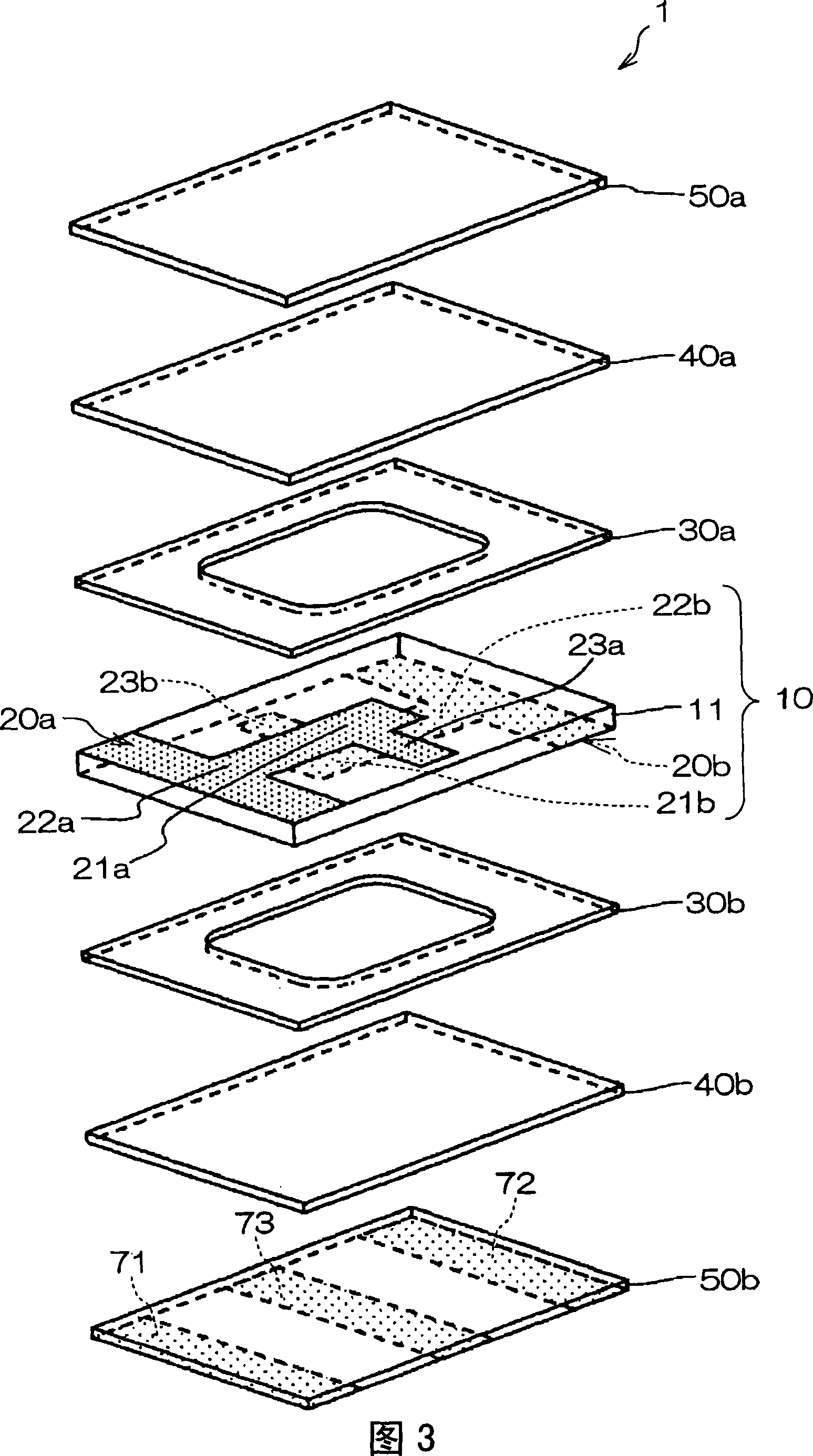

[0048] 2 is a longitudinal sectional view of the piezoelectric component shown in FIG. 1 , and FIG. 3 is an exploded perspective view of the piezoelectric component shown in FIG. 1 .

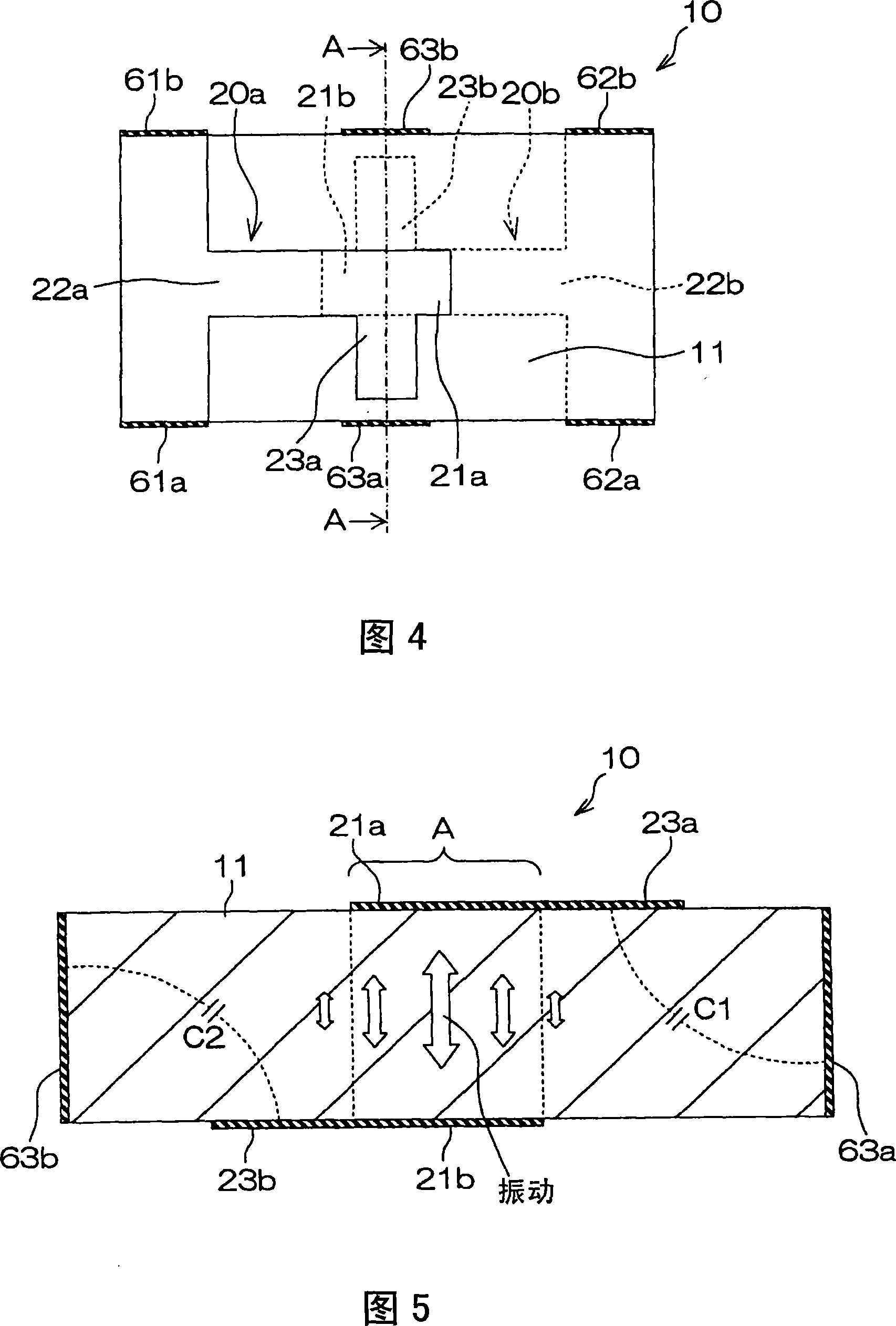

[0049] 4 is a plan view of a piezoelectric substrate used in the piezoelectric component shown in FIG. 1 , and FIG. 5 is a cross-sectional view taken along line A-A of FIG. 4 .

[0050] FIG. 6 is an equivalent circuit diagram of the piezoelectric component shown in FIG. 1 .

[0051] The structure of the piezoelectric component 1 includes: a piezoelectric vibrating element 10, which has a pair of electrodes 20a, 20b formed on both main surfaces of a piezoelectric substrate 11 so as to face each other through the piezoelectric substrate 11; a pair of frames 30a , 30b, which are arranged on both main surfaces of the piezoelectric substrate 11 so as to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com