Fume automatic ventilated spraying system for adsorption tower

A technology of automatic cooling and spraying system, applied in the field of spraying system, can solve the problems of damage to the anti-corrosion rubber lining of the absorption tower and the components of the FRP pipe demister in the spraying layer, etc., and achieve the effect of saving manpower and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

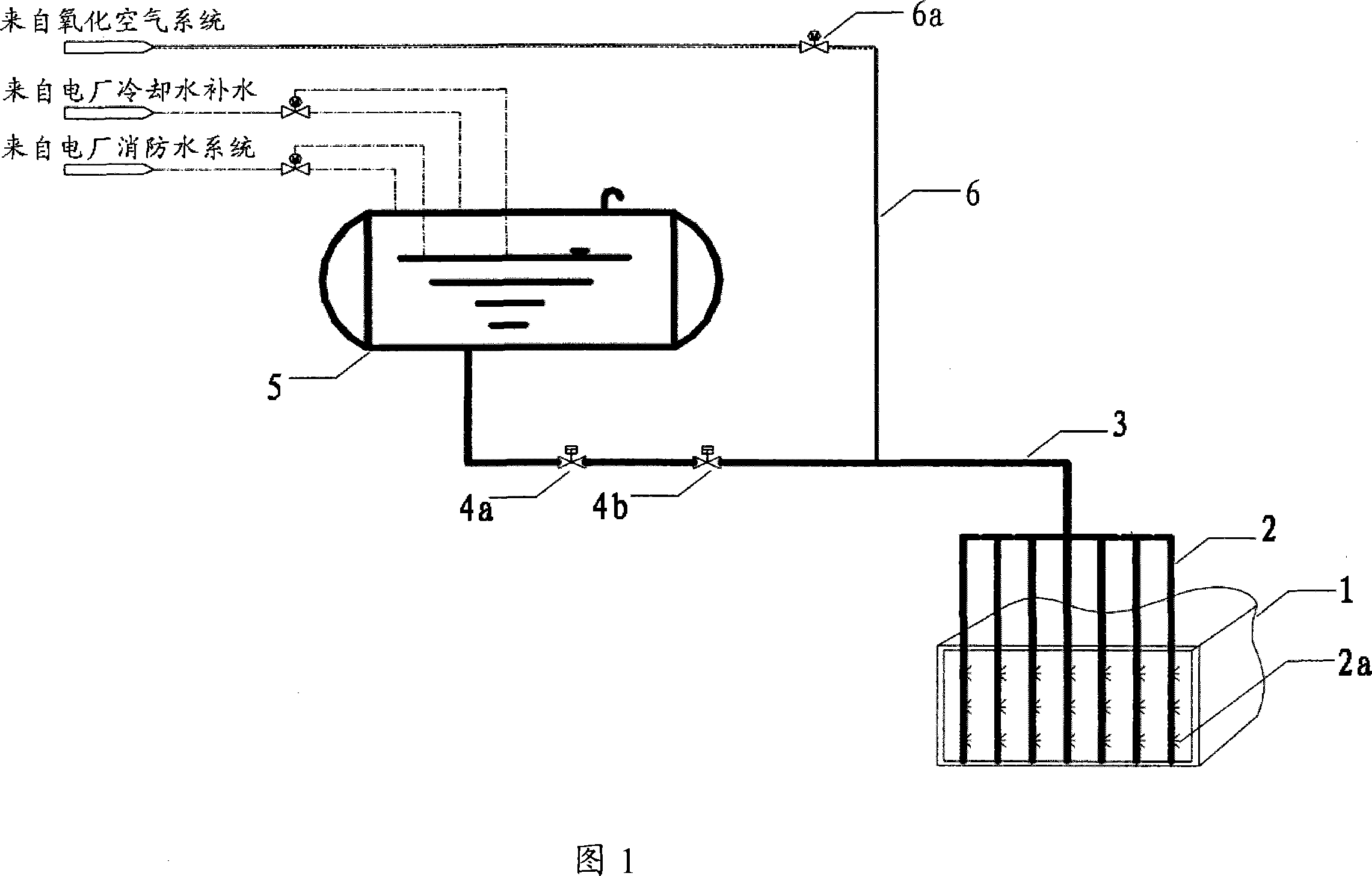

[0031] Embodiments of the present invention will be described below with reference to the accompanying drawings.

[0032] In the flue gas automatic cooling spraying system for the absorption tower of the present invention, the flue gas automatic cooling spraying system includes: a spraying subsystem and a control subsystem.

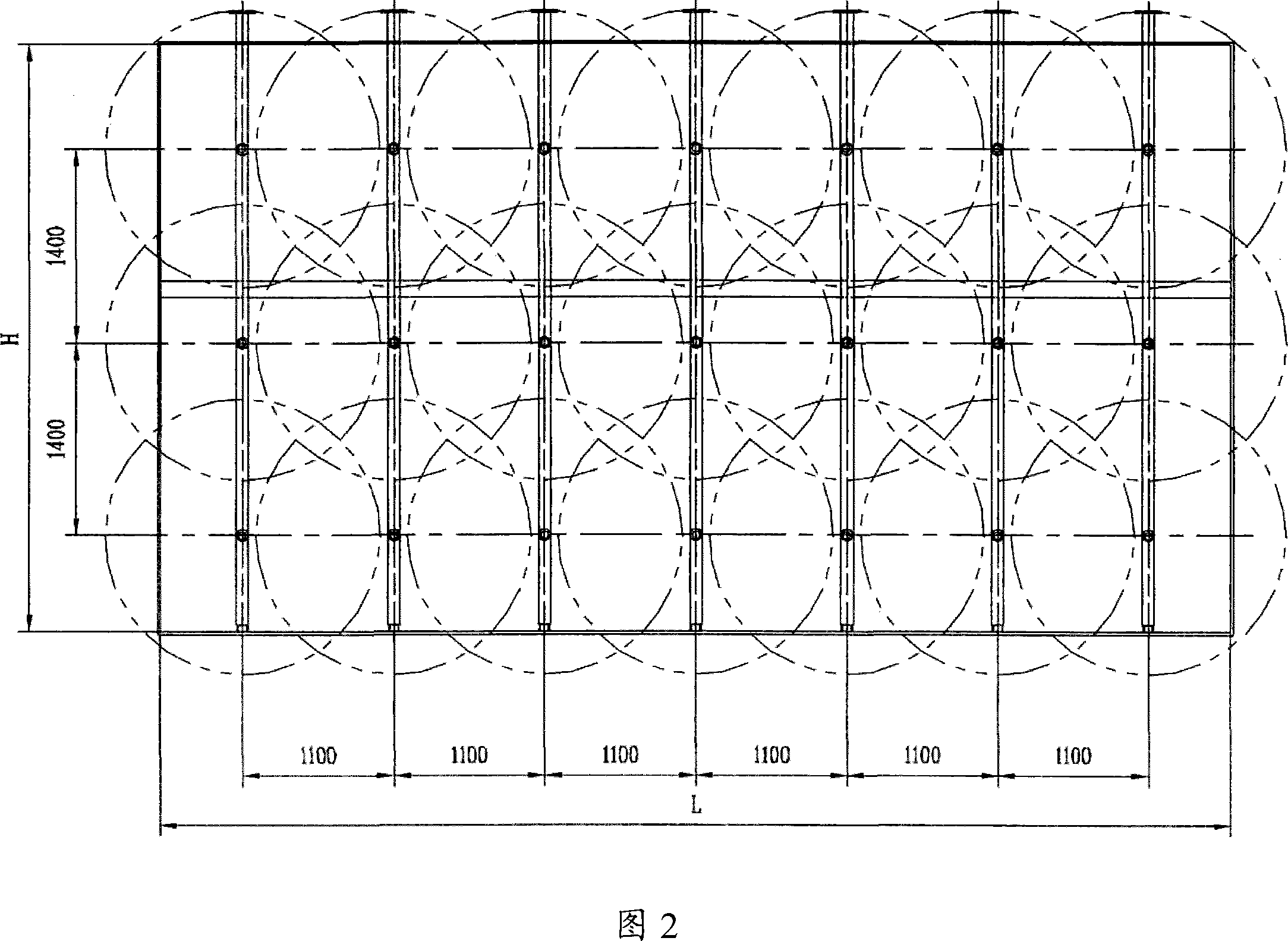

[0033] As shown in Figure 1, the spray subsystem has: an emergency cooling water tank 5 for water storage; a spray main pipe 3 connected to the emergency cooling water tank 5 at one end, and the spray main pipe 3 has at least one automatic valve 4a; The other end of the spray main pipe 3 is connected to the spray device 2, the spray device 2 is arranged in the flue 1 before the entrance of the absorption tower, and has a plurality of nozzles 2a. In practical applications, in order to achieve a more secure and tighter seal when closed, the shower main pipe 3 may also have another automatic valve 4b. Moreover, the control subsystem and the automatic valves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com