Optical fiber laser processing optical path system

A fiber laser and optical path system technology, which is used in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problem that the structure of the processing device is not compact, the laser and the processed sample cannot be observed in real time, and the distance between the laser head and the processed item cannot be adjusted, etc. problem, to achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

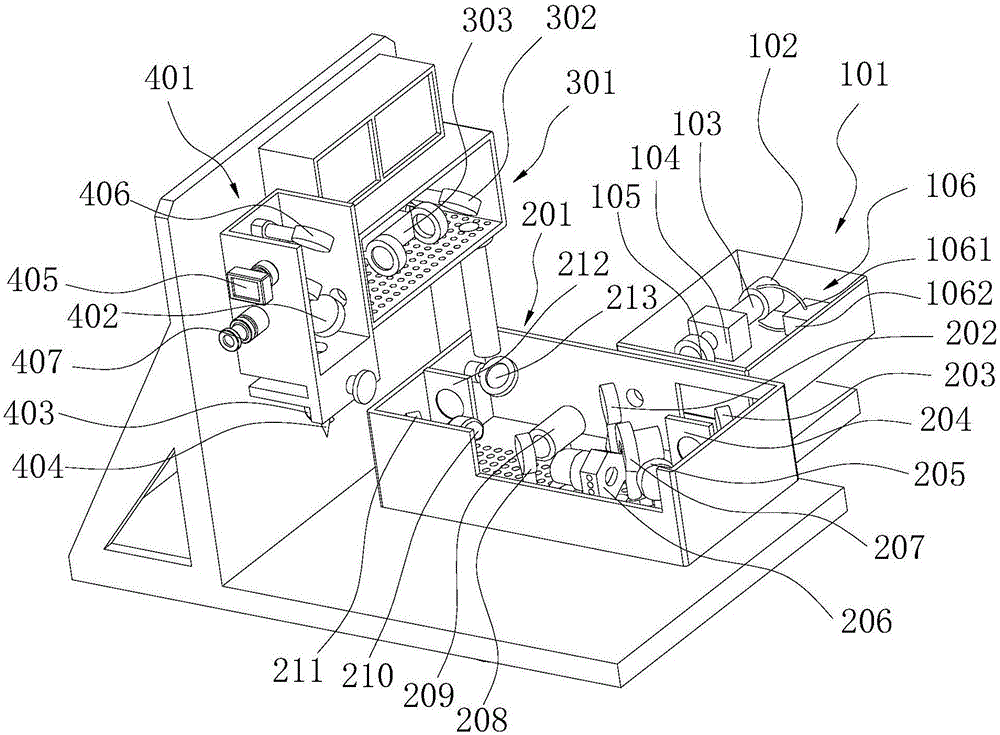

[0030] see figure 1 , figure 1 It is a structural schematic diagram of the fiber laser processing optical path system of this embodiment. The fiber laser device 101 is provided with a pump light source 102, an optical fiber 103, a resonant cavity 104, a laser amplifier 105, and a water cooling device 106. One end of the optical fiber 103 is connected to the pump light source 102. The other end is connected to the resonant cavity 104, the laser amplifier 105 is arranged on the laser light path of the resonant cavity 104, and the liquid circulation pipeline 1061 of the water cooling device 106 is connected to the pumping light source 102 and the delivery pump 1062;

[0031] The horizontal optical path device 201 is a box structure, arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com